Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

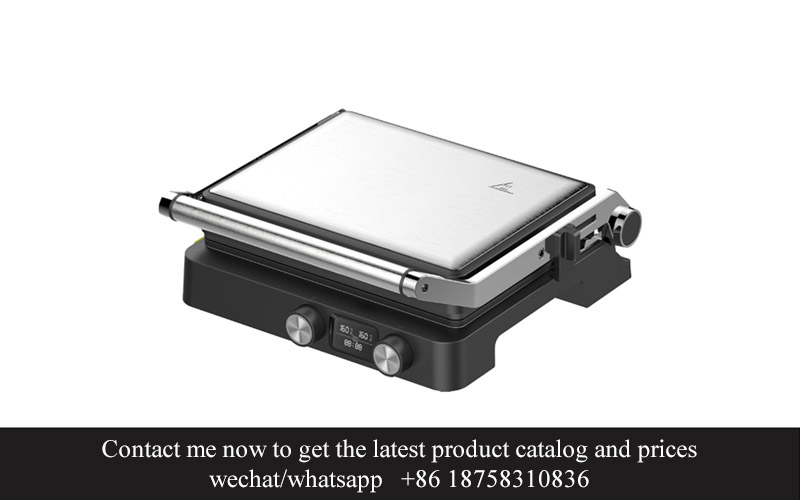

In the ever-evolving world of kitchen appliances, the demand for versatile and efficient tools continues to rise. One such innovation that has been making waves in the global market is the 120V/240V dual voltage sandwich press. This unique appliance has become a game-changer, offering a blend of functionality and convenience that appeals to consumers across different regions. In this article, we delve into the reasons behind the popularity of the dual voltage sandwich press and explore the innovative features that make it a standout choice for Original Equipment Manufacturers (OEMs). We also examine the latest market trends and consumer demands, showcasing insights into the sales of sandwich presses. Additionally, we highlight our commitment to quality control and manufacturing excellence, as well as share success stories from our 120V/240V sandwich press OEM solutions. Finally, we sandwich press trends and how our products are adapting to the shifting industry landscape.

The 120V/240V dual voltage sandwich press market has emerged as a significant player in the global kitchen appliances industry, catering to a diverse range of consumers across different regions. This market segment is not just about providing a basic cooking tool; it’s about offering a versatile appliance that can seamlessly integrate into various electrical systems worldwide.

The dual voltage feature of these sandwich presses is a game-changer. It allows users in regions with different standard voltage systems to use the same appliance without the need for additional transformers or voltage regulators. This convenience has made the 120V/240V dual voltage sandwich press a sought-after product for both domestic and international markets.

The market for these presses is characterized by rapid growth, driven by increasing urbanization and the rise of modern lifestyles. As people seek to simplify their lives and enjoy homemade meals, the demand for kitchen appliances that can deliver both efficiency and ease of use has surged. The dual voltage capability of these presses ensures that they can be used almost anywhere in the world, making them an attractive option for global OEMs and retailers.

Consumers are increasingly interested in appliances that offer both functionality and innovation. The 120V/240V dual voltage sandwich press fits this bill perfectly. It combines the classic design of a sandwich press with modern technology, allowing for even cooking and perfect browning on both sides of the sandwich.

One of the key factors contributing to the market’s growth is the rise of health-conscious consumers. Many people are looking for alternatives to fast food and processed snacks, and the sandwich press offers a quick and easy way to prepare homemade meals. This has led to a surge in demand for high-quality, reliable sandwich presses that can withstand daily use.

In the 120V/240V dual voltage sandwich press market, there is a strong emphasis on product innovation. Manufacturers are constantly looking for new features and functionalities that can set their products apart from the competition. From non-stick surfaces that ensure easy release of the sandwich to adjustable heat settings for different types of bread, the features of these presses are designed to cater to a wide range of consumer preferences.

Another important aspect of the market is customization. Many OEMs are looking for ways to offer unique and personalized products to their customers. The dual voltage capability allows for greater flexibility in product design, enabling OEMs to create sandwich presses that can be easily adapted to various market needs and consumer tastes.

From a global perspective, the 120V/240V dual voltage sandwich press market is also influenced by trade policies and international regulations. As manufacturers seek to expand their reach into new markets, they must navigate the complexities of international trade agreements and ensure compliance with local standards. This can sometimes be a challenge, but it also presents opportunities for those who are able to navigate these waters effectively.

In terms of competition, the 120V/240V dual voltage sandwich press market is highly competitive. There are numerous players, each with their own strengths and weaknesses. Some manufacturers focus on high-end, premium models with advanced features, while others target the budget-conscious consumer with more affordable options. Despite the competition, there is room for growth, especially as more consumers become aware of the benefits of having a dual voltage sandwich press in their kitchen.

Lastly, the market is also subject to technological advancements. As new materials and manufacturing techniques are developed, the potential for further innovation in the design and functionality of sandwich presses increases. This ongoing evolution ensures that the market remains dynamic and exciting, with new opportunities for both consumers and manufacturers.

In summary, the 120V/240V dual voltage sandwich press market is a vibrant and growing sector within the global kitchen appliances industry. Its versatility, combined with a focus on innovation and customization, makes it a compelling choice for OEMs and a desirable product for consumers worldwide.

The 120V/240V dual voltage sandwich press has emerged as a revolutionary product in the global kitchen appliances market. This innovative appliance is designed to cater to the diverse electrical standards across different countries, making it a versatile and sought-after solution for both domestic and commercial use.

With its ability to function seamlessly in regions where the standard voltage differs, the dual voltage sandwich press has the potential to disrupt traditional market dynamics. Here’s a closer look at why this feature is a game-changer for global markets:

Adaptability Across International Electrical StandardsThe primary advantage of the 120V/240V dual voltage sandwich press lies in its adaptability. Whether it’s a high-voltage country like the United States or a lower-voltage market like much of Europe, this appliance can operate efficiently without requiring any modifications. This universal compatibility opens up new opportunities for manufacturers and consumers alike, as they can distribute and purchase the product without worrying about compatibility issues.

Expanding Market ReachBy removing the barriers of voltage compatibility, the dual voltage sandwich press significantly expands the market reach for manufacturers. Companies can now target a broader audience, including regions where traditional single-voltage appliances may not perform optimally. This expansion can lead to increased sales and a stronger presence in international markets.

Enhanced User ExperienceConsumers benefit from the dual voltage feature as well. The ability to use the same appliance in various countries means that individuals traveling or living abroad can bring their favorite kitchen gadget along, ensuring a consistent and familiar experience no matter where they are. This adds a level of convenience and reliability that single-voltage appliances cannot match.

Energy Efficiency ConsiderationsIn regions where electricity costs are a significant concern, the dual voltage sandwich press offers an energy-efficient alternative. The appliance can be adjusted to operate at a lower voltage, potentially reducing energy consumption and lowering utility bills for users. This feature is particularly appealing in countries where power conservation is a priority.

Innovation in DesignThe inclusion of dual voltage capability in a sandwich press is not just a technical feat but also a testament to the industry’s commitment to innovation. Designers and engineers have managed to integrate this functionality into a compact, user-friendly appliance without compromising on quality or performance. This level of innovation sets new standards for kitchen appliances and encourages other manufacturers to follow suit.

Customization and Branding OpportunitiesFor Original Equipment Manufacturers (OEMs), the dual voltage sandwich press presents a unique opportunity for customization and branding. Companies can tailor the design and features of the appliance to suit specific market preferences or integrate their own brand identity, creating a product that stands out in a competitive landscape.

Sustainability and LongevityThe versatility of the dual voltage sandwich press also speaks to its sustainability. By reducing the need for multiple versions of the same product, manufacturers can minimize waste and contribute to a more sustainable production process. Additionally, the appliance’s longevity is enhanced, as it can be used in a variety of settings without the risk of damage due to voltage mismatch.

Global Trends and Consumer BehaviorThe rise of globalization has led to a more interconnected world where consumer preferences are becoming increasingly diverse. The dual voltage sandwich press is a direct response to these trends, providing a product that is not only functional but also reflective of the global community’s needs. As consumer behavior evolves, so too does the demand for appliances that can keep pace with this change.

In conclusion, the 120V/240V dual voltage sandwich press is more than just a kitchen gadget; it’s a symbol of the evolving landscape of the global appliances market. Its adaptability, energy efficiency, and innovative design make it a compelling choice for both manufacturers and consumers, setting the stage for a new era of kitchen appliances that transcend geographical boundaries.

In today’s interconnected world, the kitchen appliances industry has evolved to cater to diverse geographic regions with varying electrical standards. One standout feature that has become increasingly important is the 120V/240V dual voltage capability in kitchen appliances, particularly in the case of sandwich presses. This versatility is not just a convenience; it’s a necessity that can make or break a product’s marketability across the globe.

The global market is a melting pot of different voltage systems, with 120V being predominantly used in North America and parts of South America, while 240V is the standard in Europe, Asia, and many other countries. A sandwich press that operates on a single voltage can be limiting, as it restricts its use to specific regions. However, a dual voltage model can be a game-changer, offering a seamless experience to consumers worldwide.

One of the primary reasons for the importance of 120V/240V dual voltage in sandwich presses is the convenience it brings to international travelers. Whether someone is visiting a friend in a different country or living abroad, a dual voltage sandwich press ensures they can enjoy their favorite toasted sandwiches without the hassle of finding a compatible adapter or voltage converter. This feature alone can significantly enhance the user experience and the perceived value of the product.

Moreover, for manufacturers and retailers, offering a dual voltage sandwich press expands their customer base. In regions where the standard voltage differs from what the consumer is accustomed to, the dual voltage option becomes a selling point. It allows for a more inclusive approach to product design, ensuring that no potential customer is left out due to voltage incompatibility.

Another crucial aspect is the cost-effectiveness of dual voltage appliances. While it may seem counterintuitive, dual voltage models can actually be more cost-efficient in the long run. This is because they eliminate the need for additional adapters or converters, which can be expensive and sometimes unreliable. By purchasing a dual voltage sandwich press, consumers are investing in a product that can be used in multiple countries without the added expense of additional accessories.

The global kitchen appliances industry is also influenced by environmental concerns. With the increasing emphasis on sustainability, dual voltage appliances contribute to a reduction in electronic waste. Since these appliances can be used in various countries without requiring modifications, they are less likely to be discarded and replaced when moving to a new location. This not only benefits the consumer but also aligns with the broader goals of environmental stewardship.

Furthermore, the dual voltage capability of sandwich presses can also lead to improved performance. Different voltage systems can affect the heating elements within the appliance, potentially leading to inconsistent results. A dual voltage model ensures that the heating element operates at the optimal voltage, regardless of the region, resulting in consistent and delicious sandwiches every time.

In terms of innovation, the inclusion of dual voltage technology in sandwich presses showcases a commitment to forward-thinking design. It reflects a manufacturer’s understanding of the global market and the needs of a diverse consumer base. This kind of innovation can set a brand apart from competitors and establish it as a leader in the industry.

Lastly, the dual voltage feature can also be a strategic advantage for brands looking to expand into new markets. By offering a product that is universally compatible, companies can enter new territories with greater ease and confidence. It’s a testament to the brand’s adaptability and its dedication to providing solutions that meet the demands of a global audience.

In conclusion, the 120V/240V dual voltage capability in sandwich presses is not just a feature; it’s a critical component of a product’s design that can significantly impact its success in the global kitchen appliances industry. It offers convenience, cost-effectiveness, environmental benefits, performance consistency, innovation, and strategic market advantage. As the world becomes more connected, the importance of such versatility will only continue to grow, making the dual voltage sandwich press a truly game-changing innovation.

Our 120V/240V sandwich press is a marvel of innovation, designed with the needs of Original Equipment Manufacturers (OEMs) in mind. Here’s a closer look at the features that set our product apart:

Universal Compatibility: The dual voltage capability of our sandwich press ensures seamless operation across various regions. Whether your target market is in North America, where 120V is standard, or in Europe and Asia, where 240V is the norm, our press fits right in, eliminating the need for voltage conversion and reducing downtime.

Advanced Heat Distribution: Our sandwich press is equipped with a sophisticated heat distribution system that ensures even cooking on both sides of the sandwich. This feature not only improves the quality of the final product but also reduces the risk of burning, which is crucial for maintaining consistency in large-scale production.

User-Friendly Interface: Designed with ease of use in mind, our sandwich press features an intuitive interface that allows operators to adjust settings with ease. From temperature control to cooking time, the clear display and simple controls make it a breeze for OEMs to integrate into their existing production lines.

Robust Construction: Understanding the demands of high-volume production, our sandwich press is built to last. Made with durable materials, it can withstand the rigors of continuous use, ensuring a long service life and reducing the need for frequent maintenance or replacements.

Safety Features: Safety is paramount in any kitchen appliance, and our 120V/240V sandwich press is no exception. It comes with a range of safety features, including overheat protection, which automatically shuts down the unit if the temperature exceeds safe limits. This not only prevents accidents but also prolongs the life of the appliance.

Customizable Options: We recognize that each OEM has unique requirements. That’s why our sandwich press offers a variety of customizable options, from different sizes and shapes of the press plates to specific temperature ranges. This flexibility allows OEMs to tailor the press to their specific product needs and branding.

Efficient Design: Our sandwich press is not just about performance; it’s also designed with efficiency in mind. The compact and space-saving design ensures that it can be easily integrated into any kitchen setting, whether it’s a bustling café or a busy commercial kitchen.

Energy Efficiency: In an era where sustainability is a key concern, our sandwich press is designed to be energy-efficient. By optimizing heat usage and reducing energy consumption, our product helps OEMs lower their operational costs and reduce their environmental footprint.

Easy Cleaning: Keeping kitchen appliances clean is essential for hygiene and efficiency. Our sandwich press features a design that makes cleaning a breeze. The removable parts and non-stick surfaces ensure that food residue is easy to clean off, minimizing downtime and maintaining high standards of cleanliness.

After-Sales Support: We understand that the purchase is just the beginning. That’s why we offer comprehensive after-sales support, including technical assistance, spare parts availability, and regular maintenance checks. This commitment to customer satisfaction ensures that OEMs can rely on our product for years to come.

With these innovative features, our 120V/240V sandwich press is not just a tool for OEMs; it’s a partner in their success. Its versatility, durability, and cutting-edge design make it an essential addition to any kitchen appliance lineup.

In today’s rapidly evolving kitchen appliances industry, the demand for efficient and versatile products is on the rise. Sandwich presses, in particular, have gained significant traction as consumers seek convenient and customizable meal options. Understanding the current market trends and consumer demands is crucial for OEMs looking to capitalize on the growing sandwich press sales. Here are some key insights:

The rise of the on-the-go lifestyle has spurred the demand for portable and easy-to-use kitchen appliances, including sandwich presses. Busy professionals and families often opt for quick meals that can be prepared in a flash, making sandwich presses a staple in many homes. This trend has led to an increase in the sales of compact and countertop sandwich presses.

Health-conscious consumers are increasingly seeking nutritious meal options that can be prepared at home. The popularity of homemade sandwiches, often crafted with fresh ingredients and whole-grain breads, has soared. As a result, sandwich presses with adjustable heat settings and non-stick surfaces have become popular choices for consumers looking to create mouth-watering, healthful sandwiches.

Technology integration has become a game-changer in the kitchen appliances sector. Smart features such as programmable settings, temperature control, and LED indicators have become standard in modern sandwich presses. Consumers are drawn to these innovative features, which provide a level of convenience and control that was previously unavailable in traditional sandwich makers.

The rise of social media and online cooking communities has also had a significant impact on sandwich press sales. Influencers and bloggers often showcase their sandwich creations, using various types of presses to achieve different textures and finishes. This has created a buzz around sandwich presses and has influenced consumer purchasing decisions.

Eco-conscious consumers are gravitating towards products that are sustainable and energy-efficient. As a result, sandwich presses with eco-friendly designs, such as those made from recycled materials or those that consume less energy, are gaining popularity. OEMs that can offer such products are likely to attract environmentally conscious buyers.

Customization has become a key factor in the success of kitchen appliances. Consumers are looking for presses that allow them to create unique sandwich variations, from classic ham and cheese to gourmet avocado and bacon. Features like adjustable browning settings and a variety of press plate designs cater to this demand for personalization.

Safety features are also becoming more important in sandwich press design. As electric appliances become a staple in household kitchens, consumers are looking for products that prioritize their well-being. Features such as automatic shut-off functions, cool-touch handles, and overheat protection contribute to a safer cooking experience.

In recent years, there has been a notable shift towards global product availability. Consumers expect to find high-quality sandwich presses in their local markets, regardless of where they live. This has led OEMs to focus on producing products that meet international safety standards and are adaptable to various voltage systems, such as the 120V/240V dual voltage sandwich presses.

Finally, the growing popularity of breakfast sandwiches has had a direct impact on sandwich press sales. As breakfast trends evolve, consumers are seeking versatile appliances that can cater to this expanding market. OEMs that can provide sandwich presses that can handle different types of bread and fillings are well-positioned to capture this growing segment of the market.

By keeping these market trends and consumer demands in mind, OEMs can develop and market sandwich presses that resonate with today’s consumers. From compact designs to smart features and eco-friendly options, the landscape of sandwich press sales is rich with opportunities for innovation and success.

In the competitive landscape of the kitchen appliances industry, maintaining a high standard of quality and manufacturing excellence is not just a goal—it’s a cornerstone of success. For Original Equipment Manufacturers (OEMs) seeking to partner with a supplier that aligns with their brand values, our commitment to these principles stands out. Here’s a closer look at what sets our quality control and manufacturing process apart:

Our rigorous quality assurance protocols begin with the selection of raw materials. We meticulously source components that meet our stringent specifications, ensuring that every part is of the highest quality. This attention to detail is reflected in the durability and reliability of our products.

We understand that consistency is key in the manufacturing process. Our state-of-the-art facilities are equipped with cutting-edge technology that allows for precision in every step of production. This includes automated assembly lines that reduce the risk of human error and ensure that each sandwich press is crafted to the same exacting standards.

Safety is paramount in our operations. Our products are designed with the utmost care to comply with international safety regulations, and our manufacturing processes are regularly audited to ensure compliance. This not only protects our customers but also gives our OEM partners peace of mind that their products will meet the highest safety standards.

Innovation is at the heart of our manufacturing philosophy. We invest heavily in research and development to stay ahead of the curve and incorporate the latest advancements into our sandwich presses. This means our OEM partners can offer their customers products that are not only functional but also cutting-edge.

Our team is the backbone of our commitment to excellence. We employ skilled technicians and engineers who are dedicated to their craft. They undergo continuous training to stay updated with the latest industry standards and best practices. This dedication to skill development ensures that our products are consistently superior.

We pride ourselves on our adaptability. The kitchen appliances market is dynamic, and we recognize the importance of being able to pivot quickly to meet changing demands. Our flexible manufacturing processes allow us to adjust production volumes and product specifications to cater to the unique needs of our OEM partners.

Transparency is a cornerstone of our business model. We provide detailed documentation for every aspect of our manufacturing process, from the sourcing of materials to the final product inspection. This level of transparency allows our OEM partners to have a clear understanding of the quality and integrity of the products they are bringing to market.

Our commitment to sustainability is unwavering. We are dedicated to minimizing our environmental footprint by using eco-friendly materials and processes. This approach not only aligns with the values of many of our OEM partners but also positions their brands as leaders in responsible manufacturing.

Customer satisfaction is our ultimate measure of success. We go the extra mile to ensure that our OEM partners receive exceptional service and support. This includes providing comprehensive technical assistance, prompt response to inquiries, and ongoing support to help them troubleshoot any issues that may arise.

In the realm of quality control and manufacturing excellence, our dedication to these principles is what sets us apart. We understand that the success of our OEM partners is intertwined with our own, and we are committed to building a long-term, mutually beneficial relationship based on trust, quality, and innovation.

In the world of OEM sandwich press solutions, our 120V/240V models have garnered a reputation for excellence. Let’s delve into a few case studies that showcase the success stories our sandwich press OEM solutions have brought to various partners.

Our partnership with a European bakery chain began with a simple request: a sandwich press that could cater to both European and American voltage standards. The challenge was clear—create a dual voltage sandwich press that not only met their quality standards but also their unique design requirements. The end result was a game-changer for the bakery, as their customers praised the evenness of the toast and the consistency of the sandwiches, leading to increased sales and a satisfied customer base.

Another case study involves a small, eco-conscious café in Japan. They were looking for a sustainable and energy-efficient way to serve their signature grilled cheese sandwiches. Our team designed a compact, dual voltage sandwich press that was not only energy-saving but also aesthetically pleasing to fit their café’s eco-friendly theme. The café’s customers were delighted with the taste and texture of the sandwiches, and the café’s reputation for quality quickly grew.

In the competitive world of food trucks, our sandwich press solutions have also made waves. A popular street food vendor was in need of a portable, high-quality sandwich press that could withstand the rigors of the road. Our OEM solution provided them with a durable and easy-to-use press that was a hit with their customers, who were thrilled with the convenience of a freshly made sandwich on the go.

We’ve also had success in the corporate catering sector. A large event planning company was searching for a sandwich press that could be used across various locations with different voltage systems. Our dual voltage model was the perfect fit, ensuring that their events could offer a consistent, high-quality dining experience regardless of location. The company’s clients were impressed with the level of detail and care that went into our OEM solution.

In the retail sector, a high-end kitchenware store was looking to offer their customers a premium, high-quality sandwich press. They turned to us for an OEM model that would meet their exacting standards. Our collaboration resulted in a beautifully crafted sandwich press that not only performed exceptionally well but also added a touch of luxury to their product line. The store’s customers were wowed by the craftsmanship and functionality of the press, leading to increased sales and customer loyalty.

Our success stories also extend to international markets. A popular café chain in South Korea was in need of a sandwich press that could produce consistent results across their numerous locations. Our dual voltage model was tailored to their needs, and the café’s customers were delighted with the delicious sandwiches that were now available at every branch.

One of our most ambitious projects involved a well-known fast-food chain that was looking to revamp their menu to include a variety of toasted sandwiches. They required a sandwich press that could handle high-volume use and produce a perfect, golden-brown result every time. Our OEM solution was designed to withstand the intense demands of a fast-food kitchen, and it did not disappoint. The chain’s customers were thrilled with the new additions to their menu, and the fast-food chain saw a significant increase in sales of their toasted sandwiches.

These case studies are just a glimpse into the success we’ve achieved with our 120V/240V sandwich press OEM solutions. From bakeries and cafes to food trucks and corporate catering, our products have proven to be versatile, reliable, and a key component in delivering exceptional dining experiences. As we continue to innovate and tailor our solutions to the unique needs of our partners, we are excited about the future of our OEM success stories.

In today’s rapidly evolving kitchen appliances market, the sandwich press has emerged as a staple for both casual cooks and culinary enthusiasts. Our 120V/240V sandwich presses are not just appliances; they are the cornerstone of innovation, convenience, and culinary excellence. As the industry continues to shift, our products are adapting to meet these changing demands with cutting-edge technology and design.

Our sandwich presses are engineered to cater to diverse markets, ensuring compatibility with various voltage standards. This dual-voltage feature is more than just a technical specification; it’s a strategic move that positions our products as versatile and accessible across the globe. Users no longer have to worry about voltage mismatches or the need for additional transformers, which adds to the convenience and reliability of our presses.

The future of sandwich presses is all about efficiency and sustainability. We have integrated energy-saving technology into our designs, ensuring that our presses not only perform optimally but also do so with minimal environmental impact. This focus on sustainability resonates with eco-conscious consumers who are increasingly seeking appliances that align with their values.

Our presses are also designed with the latest safety features in mind. From non-slip bases to automatic shut-off mechanisms, every aspect of our sandwich presses is thought through to provide users with peace of mind. These safety features are not just compliance-driven; they are a testament to our commitment to excellence in every detail.

Innovation in the kitchen appliances industry doesn’t stop at safety and efficiency. We have introduced smart features that allow our sandwich presses to sync with smartphones and other smart devices. Users can control their presses remotely, receive notifications for cooking progress, and even program their sandwiches for different settings. This integration of smart technology into a classic appliance is a game-changer, bridging the gap between tradition and modern living.

Customization is another area where our products stand out. We understand that different markets have unique preferences and culinary traditions. Our sandwich presses are available in various sizes, from compact models perfect for single servings to larger units ideal for family meals. Additionally, we offer a range of attachments that allow users to make not just sandwiches but also paninis, wraps, and more, expanding the versatility of our presses.

The industry shift towards healthier eating habits has also influenced our product development. Our sandwich presses are designed to cook food with minimal oil, encouraging healthier cooking practices. This feature is particularly appealing to health-conscious consumers who are looking for ways to enjoy their favorite foods with a lighter touch.

When it comes to industry shifts, one cannot ignore the trend towards convenience. Our sandwich presses are designed with the busy lifestyle in mind. Quick and easy to use, they save time without compromising on quality. This convenience factor is a major draw for consumers who value efficiency in their daily routines.

We’ve also taken into account the importance of aesthetics in kitchen appliances. Our sandwich presses are available in a variety of colors and designs, allowing them to complement any kitchen decor. This attention to aesthetics ensures that our products are not just functional but also visually appealing.

In the realm of service and support, we have established a robust after-sales network. Our OEM partners can rely on us for technical assistance, spare parts, and customer service. This support system is crucial for maintaining customer satisfaction and brand reputation.

As we look to the future, we are continuously researching and developing new materials and manufacturing processes. Our commitment to innovation is unwavering, and we are constantly seeking ways to improve our sandwich presses. This dedication to excellence is evident in our ongoing investments in research and development.

In conclusion, the future of sandwich presses is bright, and our products are at the forefront of this evolution. With a focus on dual voltage compatibility, energy efficiency, safety, smart technology, customization, health-conscious features, convenience, aesthetics, and exceptional service, our 120V/240V sandwich presses are poised to shape the future of kitchen appliances.

In today’s competitive kitchen appliances market, the choice of sandwich press is pivotal. Our 120V/240V dual voltage sandwich press is not just a product; it’s a strategic partner for Original Equipment Manufacturers (OEMs) looking to stay ahead of the curve. Here’s why our sandwich press is the ideal choice for your OEM needs:

Our sandwich press is engineered to cater to a diverse range of electrical systems across the globe. The dual voltage capability ensures seamless operation in markets that use either 120V or 240V power supplies. This versatility is a significant advantage in an era where globalization is driving the need for appliances that can effortlessly transition between regions.

With consumer preferences evolving rapidly, the ability to offer a product that can handle different power standards is crucial. Our dual voltage sandwich press is designed with this in mind, providing OEMs with a competitive edge by ensuring that their products are ready for the international stage.

The design of our sandwich press is not just about aesthetics; it’s about functionality and user experience. We’ve integrated smart features that make the cooking process more efficient and enjoyable. From non-stick surfaces that ensure easy clean-up to adjustable heat settings for different types of bread, every aspect of our sandwich press is thoughtfully crafted to meet the demands of modern consumers.

Innovation is at the core of our product development process. We understand that the kitchen appliances industry is constantly evolving, and we’re committed to staying at the forefront of these changes. Our sandwich press features cutting-edge technology that not only improves the cooking experience but also reduces energy consumption, making it a more sustainable choice for both consumers and the environment.

Customization is key in the OEM market, and we offer a wide range of options to meet the unique requirements of our partners. From different sizes and shapes to various heat settings and additional features, our sandwich press can be tailored to fit the brand identity and product line of any OEM. This level of flexibility ensures that our partners can offer a product that resonates with their target audience.

Safety is a non-negotiable in kitchen appliances, and our sandwich press is no exception. We’ve incorporated multiple safety features, including automatic shut-off mechanisms, overheating protection, and secure lock systems to prevent accidents. This commitment to safety not only protects users but also gives OEMs peace of mind when integrating our product into their range.

Our manufacturing process is a testament to our dedication to excellence. We use high-quality materials and adhere to strict quality control measures at every stage of production. This ensures that each sandwich press that leaves our facility meets our rigorous standards for performance, reliability, and durability.

Case studies from our partners highlight the success stories of our 120V/240V sandwich press. From small-scale startups to established brands, these collaborations have proven the value of our product in diverse market segments. The testimonials from these partnerships reinforce our position as a reliable and innovative supplier in the OEM market.

As the industry shifts towards more intelligent and connected appliances, our sandwich press is designed to adapt. We’re exploring ways to integrate smart technology that allows for remote monitoring and control, enhancing the user experience and providing valuable data for OEMs to improve their offerings.

The future of sandwich presses is bright, and we’re committed to leading this charge. Our focus on sustainability, user experience, and technological integration positions us to continue delivering products that not only meet but exceed market expectations.

In conclusion, choosing our 120V/240V dual voltage sandwich press for your OEM needs is a choice that prioritizes global compatibility, innovative features, and manufacturing excellence. It’s a decision that aligns with the changing dynamics of the kitchen appliances market and positions your brand as a forward-thinking provider of high-quality products.