Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

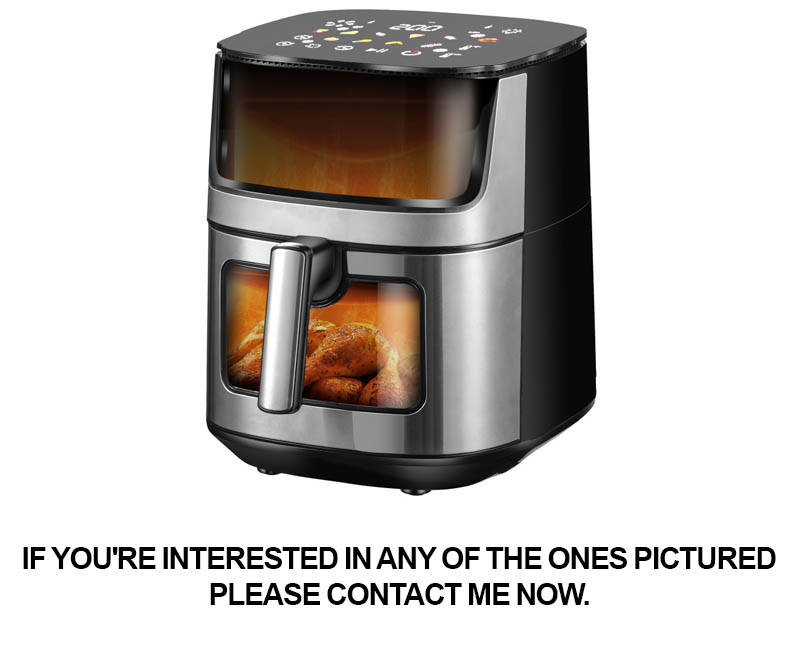

As the demand for healthier cooking options continues to soar, the air fryer has emerged as a versatile and popular kitchen appliance. Its ability to offer crispy, delicious fried foods with significantly less oil has not only caught the attention of health-conscious consumers but has also sparked innovation in the OEM industry. This article explores the significance of turnkey UL certification air fryer OEM projects, highlighting their impact on the market and offering insights into the strategies shaping the industry’s future.

The Western kitchen has seen a remarkable transformation over the years, with appliances and cooking methods evolving to cater to health-conscious consumers and busy lifestyles. At the forefront of this culinary revolution is the air fryer, a game-changer that has quietly but surely become a staple in modern kitchens across Europe and the United States.

Once a niche product, air fryers have surged in popularity due to their ability to mimic the crispy texture of fried foods without the excessive oil. This healthful alternative has resonated with health enthusiasts and those looking to reduce their calorie intake while still enjoying their favorite dishes. The compact and efficient design of air fryers has made them a convenient choice for individuals and families alike, fitting seamlessly into small apartments and bustling homes.

As the demand for healthier cooking options has grown, so too has the variety of air fryer models available. From countertop units to built-in ovens, the market has expanded to offer a wide range of sizes and features. Smart technology has also become a standard, with many models now offering programmable settings, digital displays, and even the ability to connect to smartphones for remote monitoring and control.

The convenience factor cannot be overstated. Air fryers are designed to be easy to use, with minimal cleanup required. Their ability to cook a variety of foods, from vegetables to meats to even desserts, has made them a versatile addition to any kitchen. The quick cooking times have also been a hit, as they can often prepare meals in a fraction of the time it takes to deep-fry, without sacrificing taste.

In the European market, where health and wellness are deeply ingrained in the culture, air fryers have found a particularly receptive audience. The region’s culinary landscape, rich with traditional fried dishes, has been ripe for the adoption of air fryer technology. Brands have responded by offering air fryers that cater to local tastes, featuring recipes and cooking modes that are tailored to European cuisine.

Similarly, in the United States, air fryers have become a staple in the quest for healthier eating habits. The American market has seen a surge in the sale of air fryers, with a growing number of consumers looking for ways to enjoy their favorite fried foods without the guilt. The rise of health-focused cooking shows and celebrity chefs has also played a role in promoting the air fryer as a healthy cooking option.

The environmental impact of cooking methods has also become a significant factor in consumer choices. Air fryers are a greener alternative to traditional frying, as they require less oil and produce less waste. This eco-friendly aspect has been a strong selling point, especially among environmentally conscious consumers.

The success of air fryers in the Western kitchen has not gone unnoticed by manufacturers. As a result, the industry has seen a surge in innovation, with new features and designs being introduced regularly. From air fryer ovens that can bake, roast, and dehydrate to air fryer presses that mimic the texture of pan-fried foods, the possibilities are endless.

Moreover, the rise of air fryers has opened up new opportunities for Original Equipment Manufacturers (OEMs). These companies are now able to offer turnkey solutions that include not just the air fryer itself but also the necessary certifications, such as the prestigious UL certification. This certification ensures that the air fryer meets stringent safety standards, giving consumers peace of mind when purchasing these appliances.

In conclusion, the rise of air fryers in the Western kitchen is a testament to the evolving landscape of culinary preferences and health consciousness. As the market continues to grow, it’s clear that air fryers are here to stay, bringing with them a healthier, more convenient, and eco-friendly way to enjoy our favorite foods.

In the ever-evolving OEM (Original Equipment Manufacturer) market, the demand for turnkey solutions has surged, becoming a cornerstone for success. These comprehensive packages offer manufacturers a streamlined path to market, encompassing everything from design to production, ensuring a seamless transition for clients.

The essence of a turnkey solution lies in its ability to provide a complete package that eliminates the need for customers to source components, manage logistics, or deal with regulatory hurdles. This holistic approach is particularly valuable in the fast-paced and highly competitive OEM landscape.

With the complexity of global supply chains, manufacturers often struggle with the challenges of coordinating various suppliers and ensuring quality control. Turnkey solutions mitigate these issues by consolidating the process under one roof, reducing the risk of delays and inconsistencies.

Customization is another key aspect where turnkey solutions excel. OEMs can often tailor the product to specific market needs or customer preferences without the hassle of managing multiple suppliers or handling complex negotiations. This level of flexibility is crucial for staying ahead in a market that values innovation and personalization.

Turnkey solutions also offer a significant cost advantage. By handling all aspects of production and supply, manufacturers can leverage economies of scale, reducing the overall cost per unit. This cost efficiency translates into competitive pricing for the OEM, enhancing their market position and profitability.

Moreover, turnkey solutions are designed with scalability in mind. As an OEM’s business grows, the turnkey partner can adapt and expand production capabilities, ensuring that the supply chain remains robust and capable of meeting increased demand.

Innovation is a driving force in the OEM market, and turnkey providers are often at the forefront of adopting new technologies and methodologies. This forward-thinking approach allows OEMs to bring cutting-edge products to market quickly, capitalizing on emerging trends.

The quality assurance aspect of turnkey solutions cannot be overstated. With a single point of contact for all aspects of the manufacturing process, quality control becomes more manageable and effective. This consistency is essential for building a reputation for reliability and excellence in the OEM sector.

Another benefit is the reduction in administrative overhead. By outsourcing the entire production process, OEMs can redirect their internal resources towards core business activities such as marketing, sales, and customer service, which can ultimately lead to higher customer satisfaction and retention.

Furthermore, turnkey solutions provide a level of risk mitigation that is hard to achieve independently. From intellectual property protection to navigating international trade regulations, turnkey partners can handle the complexities that often overwhelm smaller OEMs.

In a market where time-to-market is a critical factor, turnkey solutions offer a significant advantage. The integrated approach means that the product development cycle can be significantly shortened, allowing OEMs to bring products to market faster than their competitors.

The environmental impact of manufacturing processes is also a growing concern for consumers and businesses alike. Turnkey providers often prioritize sustainability, ensuring that the production of OEM products is eco-friendly and meets the latest environmental standards.

Lastly, the long-term relationship built with a turnkey partner can be invaluable. This collaboration can lead to ongoing improvements in product design, production efficiency, and market responsiveness, as both parties work together to achieve mutual success.

In summary, the importance of turnkey solutions in the OEM market is undeniable. They offer a comprehensive, cost-effective, and efficient way to bring products to market, while also providing the flexibility and innovation needed to thrive in a dynamic and competitive industry.

In the competitive OEM (Original Equipment Manufacturer) market, where products are designed, sourced, and manufactured to be branded and sold by another company, the significance of UL certification cannot be overstated. This certification is more than just a label; it’s a benchmark for quality, safety, and compliance that can make or break a product’s acceptance in the global marketplace.

The assurance of safety is paramount, especially when it comes to electronic devices like appliances. UL certification verifies that a product meets stringent safety standards, ensuring that it doesn’t pose a risk to users or the environment. This is particularly crucial in the OEM sector, where the end consumer may not be aware of the original manufacturer behind the product.

Compliance with regulatory requirements is another critical aspect. Different countries have their own safety codes and standards, which can be incredibly complex and challenging to navigate for manufacturers. UL certification simplifies this process by certifying that a product meets the necessary standards across various jurisdictions. This can save OEMs valuable time and resources that would otherwise be spent on compliance testing.

Brand reputation is a delicate matter, and UL certification can significantly bolster it. The presence of the UL mark on a product is a symbol of trust and quality. It reassures consumers that the product has been thoroughly evaluated by a reputable third-party organization, which adds a layer of credibility that can be difficult to achieve through other means.

Market access is often dependent on certifications like UL. In some regions, certain standards are mandatory for a product to be sold, and without them, entry into these markets is impossible. For OEMs, this means that not having UL certification could mean missing out on significant revenue streams and market share.

The process of obtaining UL certification is thorough and rigorous. It involves not just testing the product itself, but also the manufacturing process and quality control measures in place. This ensures that the product is consistent and reliable, which is essential for maintaining a strong reputation and customer loyalty.

Moreover, the UL certification process encourages innovation. By setting high standards, UL challenges manufacturers to improve their designs and manufacturing techniques. This can lead to more advanced and safer products, which can be a significant differentiator in the OEM market.

Cost considerations are often a concern when it comes to certification processes. However, when weighed against the potential costs of recalls, product liability lawsuits, or loss of market access, the investment in UL certification can be seen as a wise and necessary one. It’s an insurance policy for the manufacturer’s reputation and financial stability.

In the case of air fryers, a highly popular product in the OEM market, UL certification is especially important. These devices are electrical and involve high temperatures and potentially hazardous materials, making safety and compliance a top priority. The UL mark can make a significant difference in the consumer’s perception of the product’s reliability.

Additionally, the certification process ensures that the product’s marketing claims are substantiated. For instance, if an air fryer claims to be energy-efficient, UL certification would confirm that this claim is accurate. This can be a major selling point for consumers who are increasingly looking for sustainable and eco-friendly products.

Lastly, the global nature of the OEM market means that manufacturers often need to adapt their products to different cultures and preferences. UL certification can help in this regard, as it is recognized worldwide. It allows OEMs to cater to a broader customer base with a product that is not only safe and compliant but also meets the expectations of various markets.

In summary, UL certification is a cornerstone for OEMs looking to establish themselves in the market. It ensures safety, compliance, and brand reputation, while also opening doors to new markets and opportunities. The thorough nature of the certification process drives innovation and quality, making it an indispensable part of the OEM landscape.

The sleek, modern aesthetic of air fryers has become a staple in European and American kitchens, but the evolution of these appliances extends far beyond their looks. Here’s a look at the latest innovations shaping the design of air fryers for these key markets:

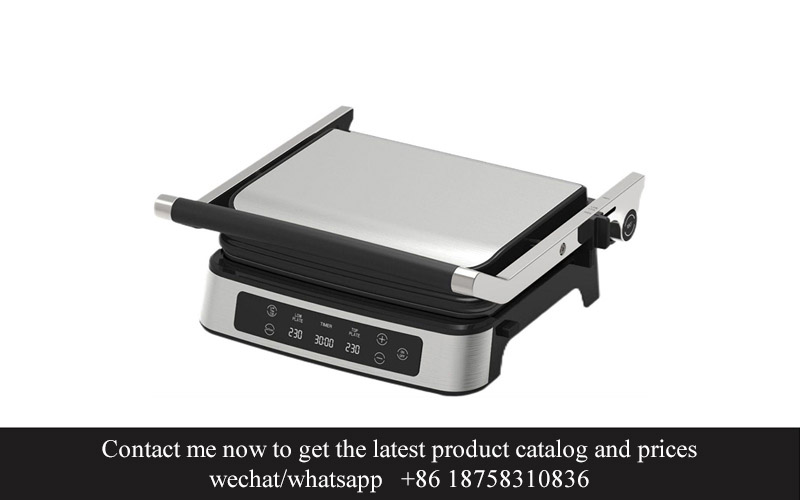

In the quest for healthier lifestyles, air fryer manufacturers are now focusing on incorporating intuitive and user-friendly interfaces. Touchscreens with clear, easy-to-read displays have replaced traditional dials and buttons, allowing users to navigate settings and cooking modes with a simple touch.

The compact and space-saving design of air fryers has always been a selling point, but recent innovations have pushed the boundaries even further. Miniature models are now available, designed to fit on a countertop or even a kitchen drawer, catering to the desire for convenience and minimalism.

With energy efficiency becoming a crucial concern, air fryers are now being equipped with eco-friendly features. Smart technology that adjusts power output based on the cooking requirements not only saves energy but also reduces the appliance’s overall carbon footprint.

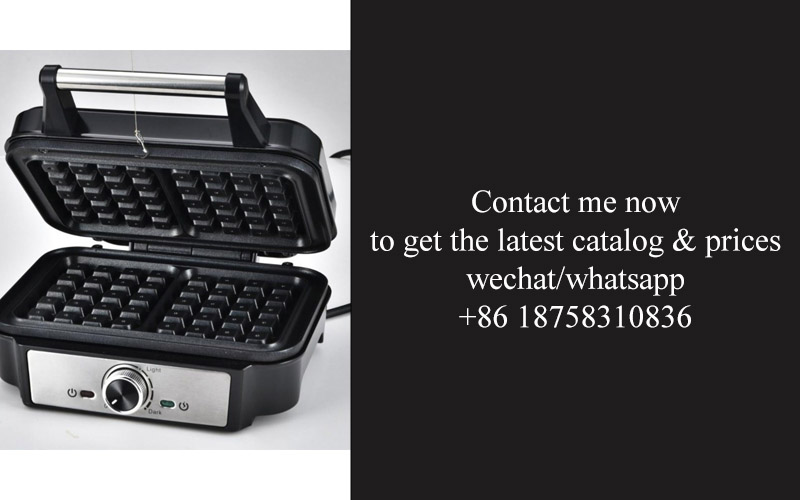

In Europe and the US, consumers are increasingly seeking versatility in their kitchen gadgets. Air fryer designs are now often multi-functional, incorporating features like rotisserie cooking, dehydrating capabilities, and even bread baking. This multipurpose approach is making air fryers a must-have for the home chef.

The use of high-quality materials has also seen a surge in air fryer design. Premium stainless steel exteriors are not only durable but also resistant to fingerprints and stains, appealing to those who value both form and function.

Air fryers have historically been noisy, but recent advancements have significantly reduced operational noise. Acoustic design improvements and quieter motor technologies have made these appliances much more pleasant to use, especially for those who enjoy cooking while relaxing in the kitchen.

Safety is a paramount concern in appliance design, and manufacturers are addressing this by integrating various safety features. From auto-shutoff timers to overheat protection and non-slip bases, air fryers are becoming safer than ever, reducing the risk of accidents.

For the tech-savvy consumer, smart connectivity has become a must-have. Air fryers that can be controlled via smartphone apps allow for remote monitoring and adjustment of cooking settings. This innovation not only adds convenience but also allows users to cook meals at their leisure.

Customizable cooking programs are another innovation that’s gaining popularity. Users can now program their air fryers to cook specific foods at varying temperatures and times, ensuring that each dish is cooked to perfection.

Incorporating the latest in smart technology, air fryers are now able to provide users with detailed analytics about their cooking sessions. From energy consumption to cooking times, these appliances offer insights that can help users optimize their cooking habits.

As sustainability becomes a driving force in consumer choices, air fryers are being designed with the environment in mind. Biodegradable packaging and eco-friendly manufacturing processes are becoming more common, aligning with the values of environmentally conscious consumers.

The design of air fryers has evolved to cater to diverse dietary needs. Features like adjustable cooking temperatures and the ability to cook with little to no oil are not only healthier but also accommodate those following low-carb, keto, or paleo diets.

Finally, the design of air fryers is now reflecting a greater focus on aesthetics. Sleek, rounded edges and contemporary colors are replacing the more traditional boxy shapes, making air fryers not just practical appliances but also pieces of modern kitchen decor.

In the ever-evolving landscape of the kitchen appliance market, air fryers have emerged as a staple in European and American households. As Original Equipment Manufacturers (OEMs) navigate this dynamic industry, understanding market trends becomes crucial in shaping their strategies. These trends not only dictate the direction of product development but also influence how OEMs position themselves in a competitive landscape.

The demand for healthier cooking methods has surged, and air fryers have capitalized on this by offering a healthier alternative to traditional frying. Consumers are increasingly aware of the benefits of air frying, such as reduced oil usage and lower calorie content, making it a preferred choice for health-conscious buyers. OEMs must stay abreast of this trend and incorporate it into their strategies by emphasizing the health benefits of their air fryer models.

Smart technology integration is another significant trend that is reshaping the air fryer market. Modern consumers are not just looking for cooking appliances; they are seeking smart devices that can enhance their daily lives. This means air fryers with WiFi connectivity, mobile app control, and recipe integration are becoming more popular. OEMs that invest in these technologies can differentiate their products and appeal to a tech-savvy audience.

Energy efficiency is a growing concern, not just for environmental reasons but also for cost savings. As energy costs rise, consumers are more likely to opt for appliances that consume less power. OEMs can leverage this trend by focusing on energy-efficient designs and certifications that highlight their product’s eco-friendliness. This not only attracts environmentally conscious consumers but also opens up new markets, such as the European Union, which has stringent energy efficiency standards.

Customization is also a key trend that is influencing air fryer OEM strategies. Consumers are looking for products that can cater to their unique needs and preferences. This could mean adjustable temperature controls, various cooking modes, or even modular designs that allow for different attachments. OEMs that offer a range of customizable options can tap into a broader market segment and increase customer satisfaction.

Sustainability is becoming a core value for many consumers, and this extends to the products they purchase. Air fryer OEMs that prioritize sustainable practices, such as using recycled materials, minimizing packaging waste, and ensuring their supply chains are ethical, can build a strong brand reputation. This trend is particularly prominent in Europe, where sustainability is deeply ingrained in consumer culture.

The rise of e-commerce has changed how consumers discover and purchase products. Air fryer OEMs need to adapt their strategies to include online marketing and sales channels. This means optimizing product listings, leveraging social media, and engaging with customers through digital platforms. Understanding the online shopping habits of European and American consumers is essential for OEMs looking to capture a larger market share.

Another trend that is reshaping the air fryer market is the demand for versatility. Consumers are looking for appliances that can perform multiple tasks, such as roasting, baking, and even defrosting. OEMs that can offer a multi-functional air fryer with a compact design are likely to attract customers who want to streamline their kitchen appliances.

Finally, the importance of brand storytelling cannot be overstated. In a crowded market, OEMs that can create a compelling narrative around their brand and products stand out. This could involve highlighting the brand’s history, commitment to innovation, or the story behind the product design. Emotional connections with consumers can lead to increased loyalty and repeat purchases.

In conclusion, market trends play a pivotal role in shaping air fryer OEM strategies. By focusing on health, smart technology, energy efficiency, customization, sustainability, e-commerce, versatility, and brand storytelling, OEMs can develop products that resonate with consumers and carve out a competitive edge in the European and American markets. Keeping a pulse on these trends and adapting accordingly is the key to long-term success in the air fryer industry.

In the competitive landscape of the air fryer market, several turnkey projects have emerged as shining examples of successful partnerships between OEMs and manufacturers. Let’s delve into a few of these case studies to understand the intricacies and successes of these collaborations.

The Eco-Friendly Air Fryer: A Project Aimed at European Health Conscious ConsumersThis project focused on creating an air fryer that not only met the stringent safety standards set by UL Certification but also catered to the growing demand for eco-friendly kitchen appliances in Europe. The design team introduced a range of materials that were recyclable and energy-efficient, appealing to the environmentally conscious consumers. The partnership between the OEM and the manufacturer resulted in a product that quickly gained traction, thanks to its innovative approach and UL Certification.

The Compact and Stylish Air Fryer: A Hit in the American MarketRecognizing the trend towards compact kitchen appliances in the US, an OEM partnered with a manufacturer to develop a sleek, space-saving air fryer. This project highlighted the importance of design in the air fryer market, as the unit was not only UL Certified for safety but also featured a modern aesthetic that resonated with American consumers. The partnership leveraged market trends to create a product that combined functionality with style, leading to strong sales and positive customer feedback.

The Smart Air Fryer: Embracing Technology for Enhanced Cooking ExperienceIn response to the tech-savvy consumer, a turnkey project focused on integrating smart technology into an air fryer. The result was a UL Certified appliance that allowed users to control their cooking through a smartphone app. This case study demonstrated how market trends towards smart kitchen appliances have influenced OEM strategies, leading to a product that not only meets safety standards but also offers convenience and connectivity.

The Healthy and Customizable Air Fryer: Tailoring Options for Diverse DietsWith a growing number of people adopting specific diets, an OEM sought to address this trend by collaborating with a manufacturer to create an air fryer that could cater to various dietary needs. The turnkey project involved developing a range of air fryer models with customizable settings for low-fat, gluten-free, and vegetarian cooking. The success of this project can be attributed to its alignment with market trends, as it offered a versatile solution that met the demands of a diverse consumer base.

The Energy-Efficient Air Fryer: Harnessing Market Demand for SustainabilityThe trend towards sustainability in the appliance market prompted an OEM to launch a turnkey project focused on creating an energy-efficient air fryer. The manufacturer worked closely with the OEM to ensure that the product was UL Certified and met the highest safety standards. The result was a highly efficient air fryer that also offered cost savings to consumers. This case study illustrates how market trends have driven the development of products that not only perform well but also contribute to a greener planet.

The Collaborative Approach: Enhancing Turnkey Projects with Market InsightsEach of these case studies showcases the collaborative approach between OEMs and manufacturers. By staying attuned to market trends and consumer demands, these partnerships have successfully brought to market turnkey air fryer projects that not only meet safety standards but also exceed customer expectations. The shared knowledge and resources have resulted in innovative products that stand out in a crowded market.

The Future of Turnkey Air Fryer Projects: Anticipating Market ShiftsThese successful turnkey projects serve as a blueprint for future developments in the air fryer market. As consumer preferences continue to evolve, OEMs and manufacturers must be ready to adapt and anticipate market shifts. By focusing on safety, innovation, and market trends, the industry can ensure that turnkey air fryer projects remain successful and sustainable in the long term.

The air fryer OEM industry is on the brink of significant transformation, and predictions for its future are as varied as they are intriguing. From technological advancements to consumer preferences, several factors are poised to reshape the landscape.

Consumers are increasingly health-conscious, and this shift is driving the demand for air fryers. As a result, OEMs are expected to focus on producing models that offer healthier cooking alternatives without compromising on taste or convenience. The integration of smart technology, such as apps that track nutritional content and cooking times, could become standard features.

Energy efficiency is another area where the industry is likely to see growth. With rising energy costs and environmental concerns, OEMs that can offer air fryers with lower power consumption and longer lifespans may gain a competitive edge. Innovations like heat exchange systems and improved insulation materials could play a crucial role in this evolution.

Customization is also a trend that’s gaining traction. Consumers are looking for appliances that can cater to their specific needs and preferences. OEMs may see success in offering air fryers with adjustable cooking settings, multiple baskets for different types of food, and modular components that allow for easy upgrades or replacements.

The rise of e-commerce has expanded the global market for air fryers. OEMs that excel in international shipping and distribution may find new opportunities in regions where the air fryer market is still emerging. This requires a nuanced understanding of local regulations and consumer behaviors, as well as the ability to adapt products to meet diverse needs.

Sustainability is a critical factor in the future outlook. OEMs that invest in eco-friendly materials and production processes are likely to attract environmentally conscious consumers. Recyclable packaging, energy-efficient manufacturing, and responsible sourcing are just a few ways companies can demonstrate their commitment to sustainability.

The integration of health and wellness into kitchen appliances is another prediction. Air fryers could become part of a larger ecosystem of smart kitchen gadgets, working in tandem to provide a holistic approach to healthy living. This could include features like meal planning, fitness tracking, and even integration with smart home systems for seamless kitchen management.

Technological advancements are not limited to just smart features; they also extend to safety and performance. OLED displays for precise temperature control, self-cleaning functions to reduce maintenance, and smart sensors that prevent overheating are all potential areas of innovation. These advancements could lead to increased consumer confidence and market share for OEMs that can implement them effectively.

The rise of private labels and direct-to-consumer (DTC) models could disrupt traditional OEM relationships. Companies that can establish strong DTC brands may have a direct line to customers, allowing for more personalized marketing and quicker response to market trends. This could mean a shift in how OEMs operate, with a greater emphasis on building their own brands and customer loyalty.

Lastly, the industry may see a rise in collaborative partnerships. OEMs that work closely with ingredient suppliers, software developers, and even foodservice providers could create more comprehensive solutions. For example, a partnership between an air fryer manufacturer and a food technology company could lead to the development of air fryer recipes and cooking techniques that are both innovative and user-friendly.

In conclusion, the future of the air fryer OEM industry is a tapestry of innovation, sustainability, and consumer-centric design. Those companies that can navigate these complex trends and adapt to the ever-changing demands of the market will likely be the ones that thrive in the years to come.

In the evolving landscape of the air fryer OEM industry, the integration of turnkey UL certification solutions has become a cornerstone for manufacturers aiming to thrive. As we delve into the nuances of this specialized market, it’s clear that the path to success is paved with strategic planning, innovation, and a keen understanding of market dynamics. Here’s a look at how these elements come together to shape the future of air fryer OEMs.

The air fryer market has seen a surge in demand, driven by health-conscious consumers and the allure of convenience. As OEMs look to capitalize on this trend, the ability to offer turnkey solutions becomes a key differentiator. These solutions not only streamline the production process but also ensure compliance with stringent safety standards, like those set by UL.

With UL certification, manufacturers gain a competitive edge by providing consumers with products that have been rigorously tested and deemed safe. This trust is invaluable in a market where safety concerns can quickly erode consumer confidence. OEMs that can offer a full-service approach, from design to certification, are better positioned to meet the needs of a diverse customer base.

One of the most significant challenges in the air fryer OEM industry is keeping up with technological advancements. Continuous innovation is necessary to stay ahead of the curve and meet the evolving demands of consumers. From energy efficiency to smart features, the landscape is constantly shifting. OEMs that invest in research and development are more likely to introduce groundbreaking products that resonate with customers.

Collaboration with design engineers is crucial in this regard. These professionals can help OEMs translate market trends into tangible product features that appeal to end-users. For instance, incorporating voice control or remote monitoring capabilities into air fryers can address the growing trend of smart home appliances.

Another critical aspect of the air fryer OEM landscape is the supply chain. A robust supply chain ensures that components are reliable, affordable, and readily available. Turnkey solutions often include supply chain management, which can help OEMs navigate the complexities of sourcing and inventory. This not only reduces costs but also minimizes the risk of production delays.

The regulatory environment plays a pivotal role in the air fryer OEM industry. Different markets have varying requirements for product safety and efficiency. For example, the European market may have different standards compared to the United States. OEMs that can adapt to these regulations and ensure compliance across multiple regions are more likely to succeed globally.

Marketing and branding are also vital components of an OEM’s strategy. With the right marketing efforts, a brand can establish itself as a leader in the air fryer market. This involves not just advertising but also storytelling—creating a narrative that resonates with consumers and highlights the unique benefits of the product.

As the industry grows, the importance of sustainability cannot be overstated. Consumers are increasingly aware of their environmental impact and are seeking out products that are eco-friendly. OEMs that prioritize sustainable practices, such as using recycled materials or reducing energy consumption, are likely to attract a loyal customer base.

The rise of e-commerce has also reshaped the air fryer OEM landscape. Online sales platforms offer new opportunities for OEMs to reach customers directly. However, it also means competing with a plethora of options. OEMs must leverage digital marketing and e-commerce strategies to stand out in this crowded space.

In the realm of customer service, OEMs that offer exceptional support can differentiate themselves. This includes everything from post-sales service to troubleshooting guides. A strong customer service infrastructure can lead to higher customer satisfaction and repeat business.

Looking ahead, the air fryer OEM industry is poised for continued growth. As consumer preferences shift towards healthier cooking methods and smart home integration, OEMs that can adapt and innovate will be well-positioned to capture market share. The key to success lies in a combination of technical expertise, market insight, and a customer-centric approach.

In conclusion, navigating the air fryer OEM landscape with turnkey UL certification solutions requires a multifaceted strategy. By focusing on innovation, compliance, supply chain management, marketing, sustainability, and customer service, OEMs can not only meet but exceed the expectations of today’s discerning consumers. As the industry continues to evolve, those who can stay agile and responsive will find themselves at the forefront of the air fryer revolution.