Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

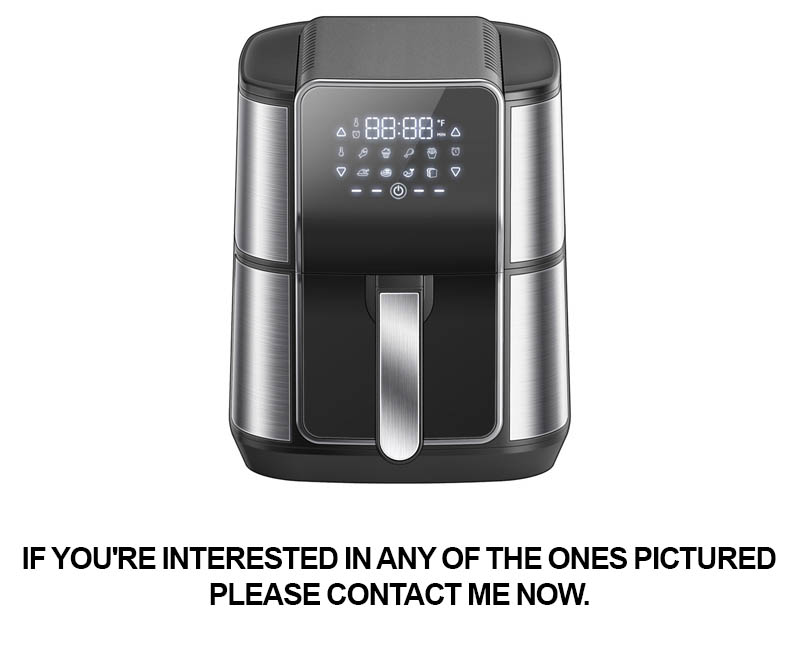

In recent years, the kitchen appliance industry has witnessed a surge in innovation, particularly with the advent of air fryers. These modern cooking devices have not only changed the way we prepare our favorite dishes but have also sparked a wave of creativity among manufacturers. As the market continues to evolve, we delve into the world of OEM air fryers and the mold-making service that’s shaping the future of kitchen appliances.

Revolutionizing Kitchen Appliances: The Rise of OEM Air Fryers with Mold Making Service

In the ever-evolving world of kitchen appliances, the air fryer has emerged as a game-changer, offering a healthier alternative to traditional frying methods. This surge in popularity has led to a new trend in the industry: OEM air fryers with mold making service. These customized appliances are not just catching on; they’re becoming a cornerstone of innovation in the culinary world.

The sleek and efficient design of air fryers has already won over many consumers, but the introduction of OEM (Original Equipment Manufacturer) options has taken this trend to another level. By offering mold making services, manufacturers are enabling brands to create unique and tailored air fryers that cater to specific market needs and consumer preferences.

One of the standout features of these custom air fryers is their ability to offer a wide range of functionalities. From adjustable temperature settings to different sizes and shapes, the possibilities are virtually limitless. This versatility allows for a diverse array of products that can be branded and sold under various labels, appealing to a broader audience.

The process of mold making for these air fryers is a meticulous one, requiring precision and expertise. It starts with the design phase, where engineers and designers collaborate to create a product that not only looks appealing but also functions flawlessly. Advanced software is used to simulate the manufacturing process, ensuring that every detail is accounted for before production begins.

Once the design is finalized, the mold making process begins. This involves crafting a mold that will be used to create the air fryer’s body. The mold is typically made from high-quality steel or aluminum, chosen for its durability and ability to withstand the heat and pressure of the manufacturing process. The mold must be perfectly aligned to ensure that the air fryers produced are uniform and meet the highest quality standards.

The mold making service also includes the creation of intricate parts that make up the air fryer’s components. These parts include the heating element, fan, and the fry basket, among others. Each component is designed to work in harmony, ensuring that the air fryer performs optimally.

As the demand for custom air fryers continues to grow, so does the importance of efficient production. Manufacturers are investing in state-of-the-art machinery to streamline the mold making process and reduce lead times. This not only allows for quicker delivery to customers but also keeps costs competitive.

One of the most exciting aspects of OEM air fryers with mold making service is the opportunity for innovation. Brands can now collaborate with manufacturers to develop unique features that set their product apart from the competition. For example, some brands are incorporating smart technology, allowing users to control their air fryer remotely via an app.

The environmental benefits of air fryers are also a major draw for consumers. These appliances use less oil than traditional frying methods, making them a more sustainable choice. With mold making services, manufacturers can create air fryers that are not only eco-friendly but also have a sleek, modern design that appeals to environmentally conscious consumers.

The market for OEM air fryers with mold making service is also being driven by health trends. As more people become aware of the health risks associated with deep-frying, they are turning to air fryers as a healthier alternative. The ability to customize these appliances to meet specific health and wellness standards is a significant advantage for manufacturers and brands alike.

In conclusion, the rise of OEM air fryers with mold making service is a testament to the power of innovation in the kitchen appliance industry. By offering customized solutions, manufacturers are not only meeting consumer demands but also driving the industry forward. As the market continues to evolve, we can expect to see even more innovative designs and features that will further revolutionize the way we cook at home.

In recent years, the kitchen appliance market has been buzzing with excitement, and one product that has captured the hearts and minds of consumers worldwide is the air fryer. This nifty gadget has transformed the way we cook, offering a healthier alternative to traditional frying methods. With its ability to cook delicious, crispy foods with minimal oil, the air fryer has become a staple in many modern kitchens.

The air fryer’s popularity can be attributed to several factors. For starters, health-conscious consumers are always on the lookout for ways to reduce their fat intake, and the air fryer delivers on this front by using a fraction of the oil compared to deep-frying. This not only makes for a healthier meal but also saves on calories and fats, making it a favorite among diet enthusiasts.

Moreover, the convenience factor cannot be overlooked. Air fryers are compact, easy to use, and require minimal cleanup. Their ability to cook a variety of foods, from crispy French fries to juicy chicken wings, in a short amount of time has won over even the busiest of cooks. The versatility of these appliances has made them a must-have for anyone looking to simplify their cooking routine.

Another reason for the air fryer’s surge in popularity is its environmental appeal. By using less oil, these fryers contribute to a reduction in kitchen waste and a smaller carbon footprint. As more people become environmentally aware, the air fryer has positioned itself as a sustainable choice that aligns with eco-friendly values.

Cooking enthusiasts have also embraced the air fryer for its ability to replicate the taste and texture of fried foods without the guilt. The technology behind air frying involves circulating hot air around the food, which creates a crispy outer layer while keeping the inside tender and juicy. This process is not only impressive but also incredibly satisfying for those who love to indulge in their favorite fried treats without the associated health risks.

The air fryer’s rise has also been fueled by social media and influencer marketing. As chefs and home cooks alike share their air fryer recipes and cooking tips online, the device has become a topic of conversation and a source of inspiration. From air fryer challenges to viral recipes, the internet has played a significant role in promoting the air fryer as a must-have kitchen gadget.

In addition to individual consumers, the air fryer has also caught the attention of the foodservice industry. Fast-casual restaurants and even some high-end establishments have started incorporating air fryers into their menus, offering customers a healthier option without compromising on taste. This trend has further propelled the demand for air fryers, as more people seek out these appliances for both home and commercial use.

The air fryer’s versatility doesn’t stop at fried foods. Many users have discovered that these appliances can also be used for roasting, baking, and even dehydrating. This multipurpose functionality means that the air fryer is not just a fryer but a versatile tool that can help streamline meal preparation in the kitchen.

As the air fryer continues to gain traction, manufacturers are responding by introducing new models with advanced features. From programmable settings to digital displays, the latest air fryers are designed to make cooking even more intuitive and enjoyable. These innovations are not only enhancing the user experience but also expanding the possibilities for what can be cooked in an air fryer.

In conclusion, the air fryer’s rise to kitchen appliance fame is a testament to its ability to cater to the modern consumer’s needs for health, convenience, and sustainability. With its wide appeal and endless cooking possibilities, the air fryer is not just a trend; it’s a game-changer that is here to stay.

An OEM air fryer with mold making service is a specialized solution that has been gaining traction in the kitchen appliance industry. This innovative approach offers manufacturers and brands the chance to create custom air fryers tailored to their specific needs and design preferences. Let’s delve into what exactly this service entails and how it benefits the market.

Mold making, in the context of OEM air fryers, refers to the process of crafting precision molds that shape the components of the air fryer. These molds are crucial for producing air fryers with consistent quality and design. The process involves designing the mold based on the desired specifications, creating a prototype, and then mass-producing the molds for large-scale manufacturing.

The molds themselves are typically made from high-quality materials like steel or aluminum, which are durable and can withstand the high temperatures and pressures of the manufacturing process. The complexity of the mold can vary greatly, depending on the design of the air fryer. Some may be simple, with a straightforward shape, while others might feature intricate details and unique features that set them apart from the competition.

When it comes to the “OEM” aspect, it stands for Original Equipment Manufacturer. This means that the mold making service is provided to a company that wants to produce air fryers under its own brand or for another company’s brand. The OEM air fryer, therefore, is a product that is designed and manufactured by one company but sold under another’s label.

One of the key advantages of opting for an OEM air fryer with mold making service is the ability to customize the design. Companies can specify everything from the size and shape of the air fryer to the type of materials used, ensuring that the final product aligns with their brand identity and meets the needs of their target market. This level of customization is not always possible with standard, off-the-shelf air fryers.

The mold making service also allows for rapid prototyping. Before a full-scale production run, manufacturers can create a working prototype of the air fryer. This prototype can then be tested for functionality, safety, and design before the molds are finalized. This iterative process helps in identifying and correcting any potential issues early on, which can save both time and resources in the long run.

In addition to customization and prototyping, the mold making service offers scalability. As market demands change, companies can modify the molds to create new models or update existing ones. This flexibility is particularly valuable in the fast-paced kitchen appliance industry, where trends can shift rapidly.

The quality of the molds is paramount in the production of air fryers. A poorly made mold can lead to inconsistencies in the product, affecting both its appearance and performance. High-quality molds ensure that every air fryer produced is uniform, with tight tolerances and a smooth finish. This not only enhances the user experience but also reduces the likelihood of product recalls due to defects.

Another aspect of the mold making service is the integration of new technologies. As the industry evolves, so do the capabilities of molds. Advanced mold-making techniques, such as 3D printing, allow for the creation of complex designs that were once impossible. These technologies can lead to air fryers with innovative features, such as adjustable temperature controls or smart connectivity, which can be a significant selling point for consumers.

The environmental impact of manufacturing processes is also a growing concern. Mold making services are increasingly incorporating sustainable practices, such as using recycled materials and reducing energy consumption during the production of molds. This not only benefits the environment but can also appeal to consumers who are looking for eco-friendly products.

In terms of the supply chain, the mold making service plays a critical role in ensuring a smooth flow of production. By providing high-quality molds, the service helps to minimize downtime and production bottlenecks. This is particularly important in the OEM model, where the manufacturer relies on the efficiency of the supply chain to meet delivery deadlines and customer expectations.

In conclusion, an OEM air fryer with mold making service is a comprehensive solution that offers customization, rapid prototyping, scalability, and quality assurance. It empowers manufacturers to bring unique and innovative air fryers to market, meeting the evolving demands of consumers and staying ahead of industry trends. With the ability to tailor every aspect of the air fryer’s design and functionality, this service is a game-changer in the kitchen appliance industry.

The surge in demand for OEM air fryers with mold making service is a testament to the evolving landscape of kitchen appliances. Here’s a closer look at the factors driving this upward trend:

The health-conscious consumer shift has significantly impacted the appliance market. With a growing awareness of the health risks associated with traditional frying methods, consumers are increasingly seeking healthier alternatives. Air fryers, which use hot air to cook food with minimal oil, have become a popular choice for those looking to maintain a balanced diet without compromising on taste.

The convenience factor cannot be overlooked. Modern lifestyles are fast-paced, and the convenience of air fryers has made them a must-have for busy households. These appliances can cook a variety of foods, from crispy French fries to tender chicken, in a fraction of the time it takes with traditional cooking methods. The ease of use and clean-up time have also contributed to the rising demand.

Innovation in technology has played a pivotal role in the popularity of OEM air fryers. With advancements such as adjustable temperature settings, programmable cooking times, and smart features that allow for remote control via smartphones, these appliances have become more versatile and user-friendly. The ability to customize the cooking experience to individual preferences has opened up new possibilities for both manufacturers and consumers.

The customization options offered through mold making service have become a game-changer for OEM air fryers. Consumers are no longer satisfied with generic models; they want products that cater to their specific needs and tastes. Mold making allows for the creation of unique designs and features that can differentiate a product in a crowded market, leading to increased consumer interest.

The environmental movement has also had a substantial impact on the demand for air fryers. With the growing concern over carbon emissions and the negative impact of food waste, air fryers have emerged as a more sustainable cooking solution. They use less energy than deep fryers and can help reduce the carbon footprint, making them an environmentally friendly choice for eco-conscious consumers.

The global market for kitchen appliances has seen a shift towards more energy-efficient products. As energy costs continue to rise, consumers are more inclined to invest in appliances that can help them save money on their utility bills. Air fryers are not only energy-efficient but also cost-effective in the long run, making them an attractive option for budget-conscious shoppers.

The rise of online shopping has made it easier for consumers to access a wider range of products, including OEM air fryers. With just a few clicks, customers can explore different models, read reviews, and make purchases from the comfort of their homes. This ease of access has helped to drive the demand for these appliances, as consumers can now compare and choose products that best meet their needs.

Lastly, the influence of social media and influencer marketing cannot be underestimated. As more people share their cooking experiences and product reviews online, the trend of owning an air fryer has become a status symbol. The buzz generated by satisfied customers and influencers has created a viral effect, further fueling the demand for OEM air fryers with mold making service.

In conclusion, the soaring demand for OEM air fryers with mold making service is a multifaceted phenomenon. It’s driven by a health-conscious consumer base, the convenience and innovation of the technology, the customization options, environmental concerns, energy efficiency, easy access through online shopping, and the influence of social media. As these factors continue to shape the market, it’s clear that the air fryer industry is here to stay and is poised for even greater growth.

In the realm of kitchen appliances, innovation has always been a driving force, pushing the boundaries of what’s possible. The rise of OEM air fryers with mold-making services has brought a wave of creativity that’s reshaping the landscape of cooking. These cutting-edge designs are not just about making cooking easier; they’re about transforming the way we interact with our kitchens.

From sleek and modern aesthetics to functionalities that enhance health and convenience, the following paragraphs delve into the innovative designs that are fueling this revolution in kitchen appliances.

Sleek and Minimalist AestheticsThe sleek, minimalist design of modern air fryers is more than just a trend; it’s a reflection of the times. Consumers today are looking for appliances that blend seamlessly into their kitchen decor without overpowering it. The clean lines and compact size of these air fryers make them a perfect match for both modern and traditional kitchen settings.

Functionality Meets FashionOne of the key innovations in the OEM air fryer market is the integration of fashion with function. Designers are now creating appliances that not only look good but also serve a purpose. For example, some models come with digital interfaces that are not only easy to use but also visually appealing, offering a touch of sophistication to the kitchen counter.

Health and Wellness-Oriented FeaturesAs awareness of health and wellness grows, so does the demand for kitchen appliances that support these lifestyle choices. Air fryers with mold-making services are responding by incorporating features that promote healthier cooking. For instance, models with adjustable temperature controls allow users to tailor the cooking process to their preferred level of fat content, reducing the calorie count without sacrificing flavor.

Customization and PersonalizationThe ability to customize and personalize kitchen appliances is a game-changer. With mold-making services, OEM air fryers can be tailored to specific customer needs or brand identities. This means that not only can you get an air fryer that fits your kitchen’s style, but you can also choose the exact features and design elements that you prefer, making it a truly unique piece of kitchen equipment.

Smart Technology IntegrationSmart technology has made its way into kitchen appliances, and air fryers are no exception. New models are being equipped with features like WiFi connectivity, allowing users to control their appliances remotely. This not only adds a layer of convenience but also opens up possibilities for app-based recipes and cooking tutorials, making the air fryer an interactive and educational tool.

Environmental ConsiderationsInnovation isn’t just about creating something new; it’s also about considering the impact on the environment. Air fryers that are designed with eco-friendly materials and energy-efficient technology are becoming increasingly popular. Mold-making services can help manufacturers create appliances that are both sustainable and durable, reducing waste and long-term costs for consumers.

Safety and Ease of UseSafety has always been a top priority in kitchen appliances, and innovative designs are pushing the envelope even further. Features like automatic shut-off, non-slip bases, and easy-to-clean surfaces are becoming standard in modern air fryers. The goal is to make cooking safer and more accessible to all users, regardless of their skill level.

Culinary CapabilitiesInnovation in air fryer design isn’t just about the appliance itself; it’s about what it can do. New models are offering a wider range of cooking options, from crispy fried foods to tender roasts. With advanced heat distribution and precise temperature controls, these air fryers are capable of replicating the texture and taste of deep-fried foods without the guilt.

Ergonomic and Comfortable to UseThe design of kitchen appliances has evolved to prioritize the user experience. Air fryers with mold-making services are now incorporating ergonomic handles, intuitive controls, and compact storage solutions. These features make the appliance not just a cooking tool but also a part of the kitchen that adds to the overall comfort and convenience of cooking.

As the demand for OEM air fryers with mold-making services continues to soar, it’s clear that innovation is the key to staying ahead in the kitchen appliance market. By focusing on aesthetics, functionality, health, and sustainability, manufacturers are not only meeting consumer expectations but also setting new standards for what’s possible in the kitchen.

In the realm of kitchen appliances, the rise of OEM air fryers has been nothing short of a game-changer. These fryers, tailored to meet the specific needs of Original Equipment Manufacturers (OEMs), are not just a product; they are a solution that’s reshaping the market. The process of custom mold making plays a pivotal role in this transformation, offering a plethora of benefits that are driving the demand for these specialized air fryers.

The precision and uniqueness of custom molds are the cornerstone of the OEM air fryer market. These molds are designed to cater to the exact specifications of each manufacturer, ensuring that the air fryers they produce are not just functional but also aesthetically pleasing and durable. Let’s delve into the various advantages that custom mold making brings to the table.

Tailored Aesthetics: One of the most apparent benefits of custom mold making is the ability to create air fryers that stand out visually. Each OEM can choose from a wide array of materials, colors, and finishes to match their brand identity or to cater to specific market trends. This level of customization allows manufacturers to offer products that resonate with consumers on an emotional level, making them more likely to choose their brand over competitors.

Enhanced Functionality: Custom molds enable the creation of air fryers with unique features and functionalities. From adjustable temperature controls to various cooking modes, these fryers can be designed to meet the exact cooking requirements of different food types. This not only enhances the user experience but also opens up new possibilities for consumers who are looking for more versatile kitchen appliances.

Quality Assurance: The use of custom molds ensures a high level of quality control. Each mold is meticulously crafted to produce air fryers with precise dimensions and uniformity. This consistency in manufacturing leads to a product that is reliable and performs consistently, reducing the likelihood of defects and customer returns.

Cost Efficiency: While custom mold making may seem like an expensive venture, it can actually lead to cost savings in the long run. By creating molds that are specific to their needs, OEMs can avoid the costs associated with modifying standard molds or dealing with subpar products that require frequent repairs or replacements. Additionally, the ability to produce large batches of air fryers with a single mold can lower unit costs.

Environmental Impact: Custom mold making can also contribute to a more sustainable approach to manufacturing. By producing air fryers that are more durable and less likely to break, OEMs can reduce waste and extend the lifespan of their products. This not only benefits the environment but also enhances the perceived value of the product in the eyes of the consumer.

Market Adaptability: The flexibility offered by custom molds allows OEMs to quickly adapt to changing market demands. Whether it’s a shift in consumer preferences or the introduction of new technologies, having the ability to modify molds means that manufacturers can bring new products to market swiftly, staying ahead of the competition.

Innovation and Differentiation: Custom mold making fosters innovation within the OEM air fryer market. Manufacturers can push the boundaries of design and functionality, leading to a continuous stream of new products that differentiate them from their competitors. This differentiation is crucial in a crowded marketplace where consumers are bombarded with choices.

Brand Loyalty: The unique and high-quality air fryers produced through custom mold making can help build brand loyalty. When consumers experience the excellence of a product that has been crafted with attention to detail, they are more likely to become repeat customers and advocates for the brand.

Global Reach: With the ability to create air fryers that cater to specific regional preferences and standards, OEMs can expand their global reach. Custom molds allow for the creation of products that are not only safe and compliant with international regulations but also resonate with local tastes and cooking habits.

In conclusion, the benefits of custom mold making for OEM air fryers are multifaceted. From enhancing aesthetics and functionality to ensuring quality, cost efficiency, and sustainability, these advantages are driving the demand for tailored air fryers in the market. As innovation continues to shape the kitchen appliance industry, the role of custom mold making will undoubtedly remain a cornerstone in the success of OEMs looking to stand out in a highly competitive landscape.

In the world of OEM air fryers, several brands have managed to carve out a niche for themselves, each with their unique approach and innovative solutions. Let’s delve into a few success stories that highlight the impact of custom mold making on the OEM air fryer market.

Story 1: The Eco-Friendly Air FryerOne company that stands out is EcoChef, known for its commitment to sustainability. They leveraged custom mold making to create an air fryer that is not only efficient but also eco-friendly. The molds allowed them to design a fryer with a unique shape that maximizes airflow while reducing energy consumption. The result was a product that not only appealed to environmentally conscious consumers but also won awards for design and innovation.

Story 2: The Compact Kitchen GadgetAnother success story comes from CompactGadgets, a brand that targets urban dwellers with limited kitchen space. Their custom mold-making service enabled them to develop an air fryer that is smaller than traditional models without compromising on performance. The innovative design won over customers who appreciated the ease of use and the ability to enjoy their favorite fried foods without taking up valuable countertop space.

Story 3: The Smart Air FryerSmartAirFryer Co. took the concept of smart appliances to a new level by integrating advanced technology into their air fryer designs. Custom molds allowed them to create intricate designs that house the latest smart features, such as Bluetooth connectivity and a mobile app for remote control. This fusion of technology and culinary innovation turned their air fryers into must-have gadgets for tech-savvy consumers.

Story 4: The Health-Conscious SolutionHealthyFry, a brand focused on providing health-conscious consumers with alternative cooking methods, used custom mold making to create an air fryer that could cook a variety of foods with minimal oil. The molds helped them design a fryer with a special non-stick coating that withstands high temperatures and ensures food doesn’t stick, making it a favorite among those looking to reduce their fat intake.

Story 5: The Customizable Air FryerCustomizeIt Air Fryers caught the attention of the market by offering a line of fryers that customers could personalize. With custom molds, they developed a range that allowed buyers to choose from different colors and even add their initials or names to the appliance. This level of customization turned the air fryer into more than just a kitchen gadget; it became a statement piece that customers could proudly display in their homes.

Story 6: The Global AppealGlobalFryAir, a company that distributes its products worldwide, used custom mold making to create air fryers that cater to various cultural preferences. By developing molds that accommodate different types of food preparation, they were able to offer products that were well-received in diverse markets. This approach not only expanded their customer base but also positioned them as a global leader in air fryer technology.

Story 7: The Budget-Friendly OptionAffordableAirFryers hit the market with a budget-friendly air fryer that still offered high-quality features. Custom molds allowed them to create a fryer that was both cost-effective and efficient. The affordability of their product made air frying accessible to a wider audience, contributing to the soaring demand for air fryers in general.

Story 8: The Brand StorytellingOne of the most compelling success stories is that of StorytellerAirFryers, which used custom mold making to design fryers that told a story. Each mold was crafted to create a unique design that represented a different cultural landmark or famous invention. This not only added a touch of nostalgia to the cooking experience but also made their air fryers a conversation starter.

These case studies illustrate the power of custom mold making in the OEM air fryer market. By allowing companies to tailor their products to specific needs and preferences, custom molds have been a key factor in driving innovation and success in this rapidly growing industry.

In the ever-evolving landscape of kitchen appliances, air fryers have emerged as a game-changer. These nifty gadgets have not only transformed the way we cook but have also sparked a wave of innovation. As we look ahead, several trends and predictions are shaping the future of air fryers, promising a blend of convenience, health, and technological advancement.

The integration of smart technology is one of the most notable trends. Air fryers are becoming increasingly connected, allowing users to monitor and control their appliances remotely via smartphones. This connectivity isn’t just about convenience; it’s also about safety and efficiency. Imagine being able to turn off your air fryer from the comfort of your bed if you forgot to switch it off before leaving the house.

Energy efficiency is another key trend. With rising energy costs and growing environmental concerns, manufacturers are focusing on creating air fryers that consume less power without compromising performance. This not only saves users money on their utility bills but also contributes to a greener planet.

Health and wellness are at the forefront of consumer interests, and air fryers are responding by offering healthier cooking options. The allure of deep-frying has always been its ability to create crispy textures, but with air fryers, users can achieve a similar result with minimal oil. This is a significant shift towards healthier eating habits, as air-fried foods can have up to 80% less fat compared to their deep-fried counterparts.

Personalization is also on the rise. Consumers are looking for appliances that cater to their specific needs and preferences. Air fryer brands are responding by introducing a variety of sizes, capacities, and features. From compact models perfect for small apartments to large ones suitable for families, the market is becoming more diverse, allowing users to find an air fryer that fits their lifestyle.

Sustainability is becoming a crucial factor in the appliance industry, and air fryers are not exempt. Brands are exploring eco-friendly materials and practices in their manufacturing processes. This includes the use of recycled plastics, energy-efficient components, and responsible sourcing of materials.

The rise of electric kitchen gadgets has led to an increase in safety features. Air fryers are now equipped with features like automatic shut-off, overheating protection, and child safety locks. These innovations ensure that users can enjoy their cooking without worrying about accidents.

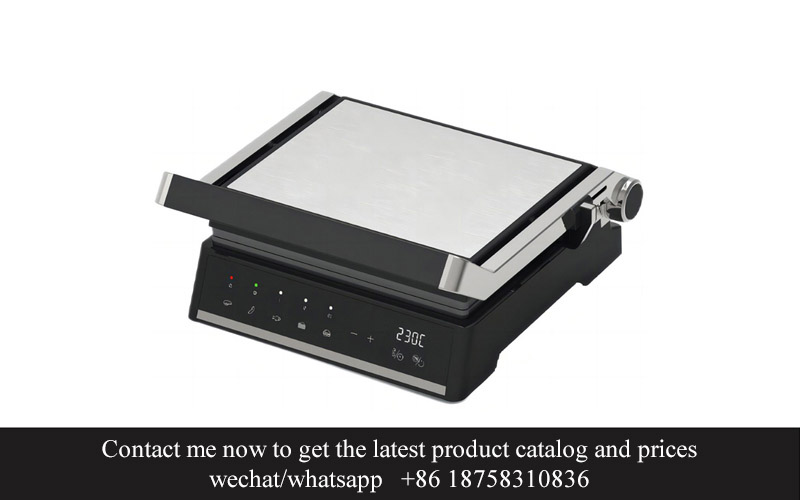

Another exciting trend is the fusion of air fryers with other cooking technologies. We’re seeing a blend of air frying with grilling, baking, and roasting capabilities. This integration opens up a world of culinary possibilities, allowing users to create a wide range of dishes with a single appliance.

As we look to the future, one prediction is that air fryers will become even more intuitive. Voice control and AI integration could become standard, making cooking even more hands-free and accessible. Imagine giving a simple voice command to start cooking, and the air fryer takes over, adjusting temperatures and times automatically.

Health-conscious consumers are likely to see more options for air fryer accessories. Brands may introduce attachments for different cooking methods, such as a rotisserie function or a pizza crust setting. This would allow users to expand their cooking repertoire without needing multiple appliances.

Lastly, the market is poised to see a surge in the use of air fryers for commercial purposes. From restaurants to food trucks, the convenience and health benefits of air frying are making them a popular choice in the foodservice industry. This could lead to the development of more robust and commercial-grade air fryers designed to withstand heavy use.

In conclusion, the future of air fryers is bright, with a focus on smart technology, energy efficiency, health, personalization, sustainability, safety, integration, and innovation. As the market continues to evolve, we can expect air fryers to become an even more integral part of modern kitchens, offering users a versatile, healthy, and convenient way to cook.

In the ever-evolving landscape of kitchen appliances, OEM air fryers are not just a trend; they’re a game-changer. These innovative cooking devices have captured the hearts and kitchens of consumers worldwide, and for good reason. They offer a healthier alternative to traditional frying methods, reducing oil content while still delivering delicious, crispy results. As we look to the future, the potential for growth and innovation in this sector is immense. Here’s why OEM air fryers are set to dominate the culinary scene for years to come.