Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

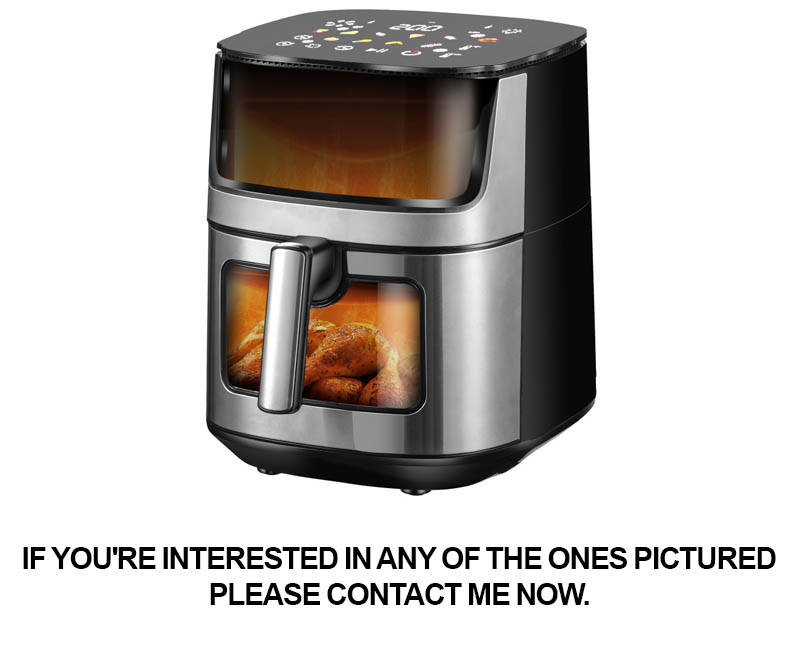

Navigating the world of air fryer manufacturers can be a daunting task. With so many options out there, it’s crucial to find a reliable factory that not only produces high-quality products but also understands your specific needs. In this article, we’ll delve into the process of identifying a trustworthy air fryer factory, focusing on key aspects such as product quality, certifications, factory facilities, customization capabilities, and the importance of networking and comparing quotes. By the end, you’ll be equipped with the knowledge to make an informed decision and secure a partnership with a manufacturer that aligns with your brand’s values and expectations.

Navigating the world of kitchen appliances can be a daunting task, especially when it comes to air fryers, which have surged in popularity for their health benefits and convenience. At the heart of this market is the air fryer factory, the place where the magic happens. Choosing the right factory is crucial for several reasons, and here’s why:

Firstly, the quality of the air fryer you purchase is directly tied to the factory that produces it. A reliable factory adheres to stringent quality control measures, ensuring that each unit meets or exceeds industry standards. This means you’re getting a product that’s not only durable but also safe to use, which is paramount when dealing with electrical appliances.

Secondly, the reputation of the factory reflects on the product. A factory with a history of delivering high-quality air fryers is likely to have a strong customer base and positive reviews. This is a good indicator that the company stands behind its products and is committed to customer satisfaction.

Thirdly, a reliable air fryer factory often invests in the latest technology and equipment. This not only allows for more efficient production but also means that the factory can offer innovative features and designs that set their products apart from the competition.

Moreover, when you partner with a reputable factory, you gain access to a wealth of technical support and after-sales service. This is particularly important for businesses that rely on air fryers for commercial use, as they need to ensure that their appliances are always in top condition.

Additionally, a trustworthy factory is more likely to offer competitive pricing without compromising on quality. They understand the value of a good deal and are often willing to negotiate terms that work for both parties, whether you’re a small business owner or a large-scale distributor.

Another aspect to consider is the factory’s capacity to scale production. As demand for air fryers continues to grow, you want to ensure that your supplier can meet your needs without delay. A reliable factory has the infrastructure and resources to handle increased orders without sacrificing quality.

Furthermore, environmental responsibility is a key factor in today’s market. A factory that prioritizes sustainability not only contributes to a healthier planet but also offers eco-friendly products that resonate with environmentally conscious consumers.

When it comes to design and innovation, a reliable air fryer factory is at the forefront of new developments. They are constantly experimenting with materials, technology, and user experience to create products that are not just functional but also aesthetically pleasing and user-friendly.

Lastly, a good factory understands the importance of customization. Whether you need a product with specific features or branding, a reliable factory can work with you to create a solution that meets your unique requirements. This level of flexibility is crucial for businesses looking to differentiate themselves in a crowded market.

In summary, the reliability of an air fryer factory is a multi-faceted consideration that encompasses quality control, reputation, technological innovation, customer service, pricing, scalability, environmental responsibility, design, and customization. By taking the time to find a factory that excels in these areas, you’re setting yourself up for success in the competitive kitchen appliance market.

Navigating the vast landscape of air fryer manufacturers can be daunting, but pinpointing the right one for your needs is crucial. To ensure you’re working with a quality air fryer manufacturer, there are several key indicators you should look out for:

The first and foremost consideration is the reputation of the manufacturer. A company with a strong track record in the industry is more likely to produce reliable and high-quality air fryers. Check online reviews, testimonials, and industry awards to gauge their standing.

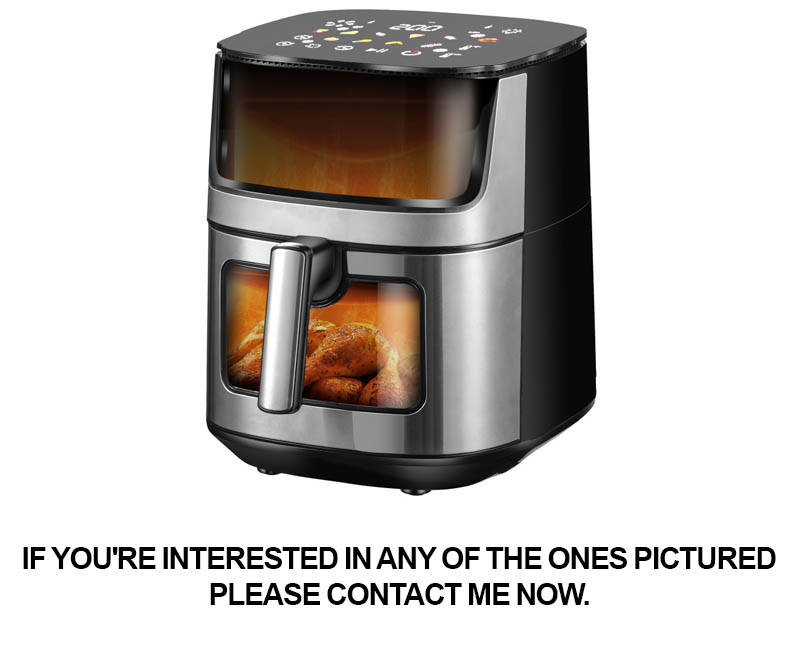

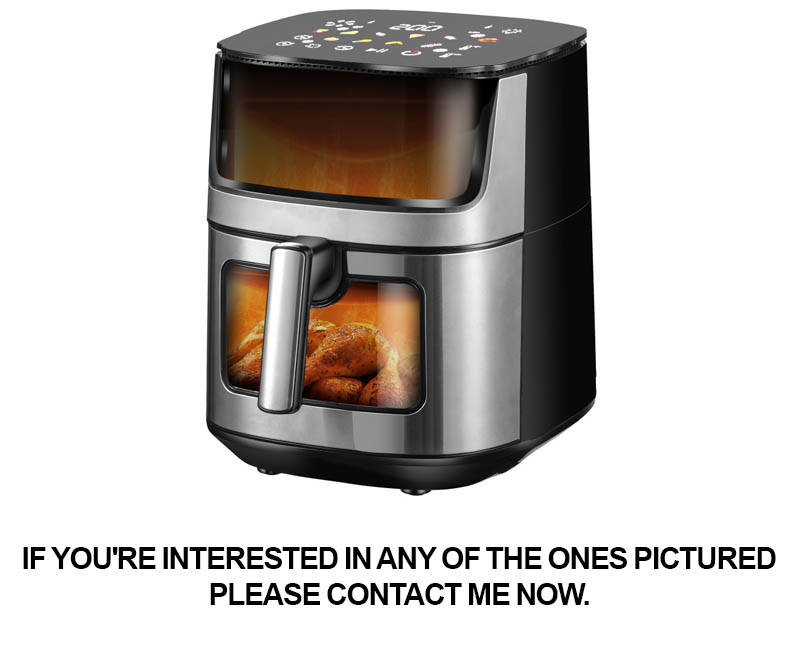

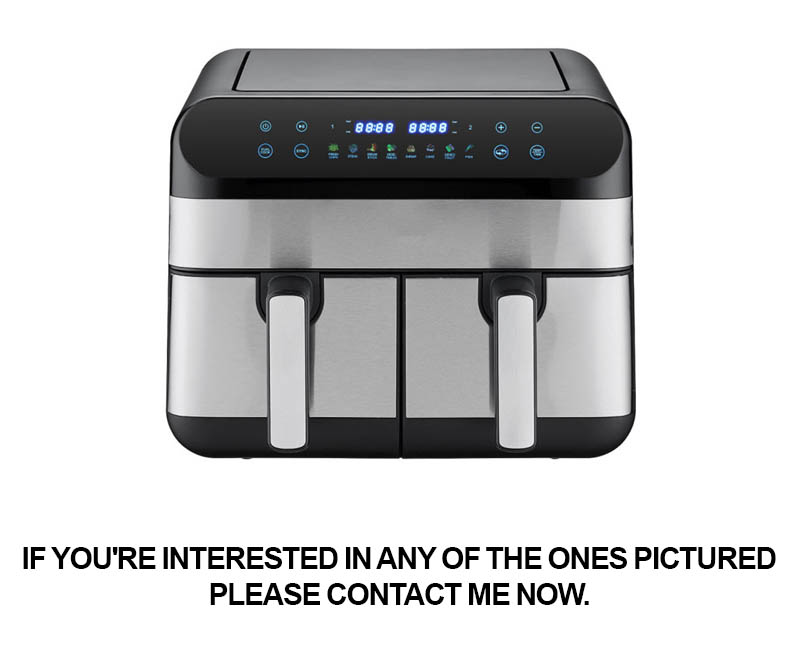

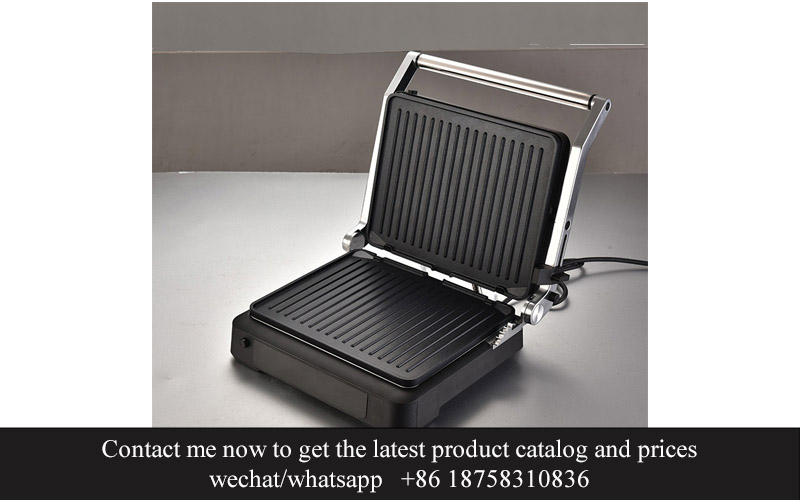

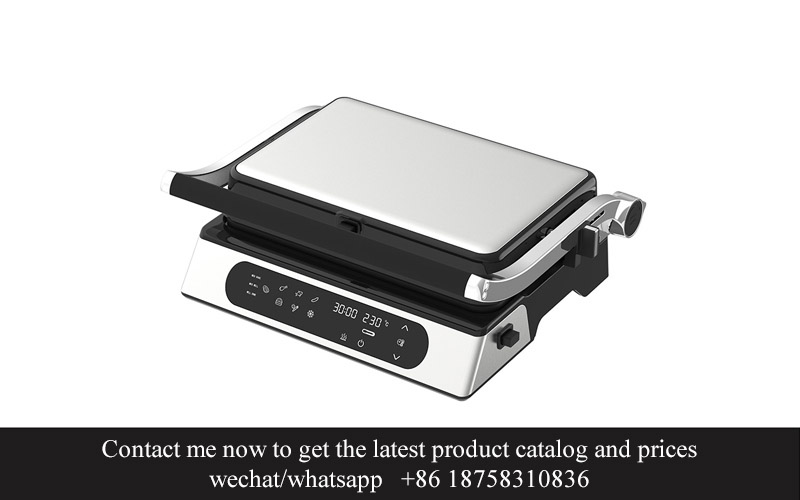

Next, examine the range of products offered by the manufacturer. A diverse product line indicates a company that is committed to innovation and meeting a variety of consumer needs. Look for a manufacturer that not only offers standard air fryers but also has a range of models with different capacities, features, and price points.

Quality materials are the backbone of a durable air fryer. A reputable manufacturer will use robust materials like stainless steel for the body and high-quality plastic for the components. Pay attention to the finish and craftsmanship; a well-constructed air fryer should have smooth edges and no rough spots.

The presence of advanced technology within the air fryers is another indicator of a quality manufacturer. Look for features like smart controls, adjustable temperature settings, and programmable cooking modes. These innovations not only enhance the cooking experience but also ensure consistent results every time.

Safety should be a top priority for any air fryer manufacturer. Ensure that the products comply with international safety standards and certifications. Look for features like non-toxic coatings, automatic shut-off functions, and easy-to-clean components to indicate a focus on safety.

Customer support is a reflection of the manufacturer’s commitment to quality. A quality air fryer manufacturer will offer excellent pre-sales and after-sales service. Check for readily available customer service options, clear warranty policies, and responsive support teams.

Another key indicator is the manufacturing process. A quality manufacturer will invest in modern production facilities and advanced machinery to ensure precision and efficiency. They should also have a robust quality control system in place to inspect each unit before it leaves the factory.

Innovation is a hallmark of a top-tier air fryer manufacturer. They should be at the forefront of new technologies and design trends, continuously improving their products. Look for evidence of research and development, such as partnerships with universities or the introduction of eco-friendly materials.

Pricing is also a telling factor. While the cheapest option may not always be the best, a manufacturer that offers competitive pricing without compromising on quality is more likely to be reliable. Beware of manufacturers that sell products at significantly lower prices than their competitors, as this could be a sign of lower quality materials or substandard construction.

Lastly, consider the manufacturer’s distribution network. A company with a wide reach and established partnerships with retailers and online platforms can provide a broader market access and a higher level of customer trust.

By considering these key indicators, you can make an informed decision when selecting an air fryer manufacturer that aligns with your standards for quality, safety, innovation, and customer satisfaction.

Navigating the sea of air fryer manufacturers can be daunting, but delving into their industry reputations and reviews is like uncovering hidden gems. Here’s how to sift through the noise:

Leverage Online Forums and Social MediaOnline forums and social media platforms are treasure troves of information. From Reddit’s appliance subreddits to Facebook groups dedicated to kitchen gadgets, these communities are buzzing with real-world experiences. Pay attention to the conversations—do customers praise the manufacturer’s reliability and durability, or are there frequent complaints about poor quality or customer service?

Check Professional Review SitesSites like Consumer Reports and CNET offer detailed reviews of kitchen appliances, including air fryers. These platforms often conduct thorough tests and compare products based on a variety of criteria, such as cooking performance, energy efficiency, and safety features. Look for patterns in the reviews; a consistent high score is a good sign of a quality manufacturer.

Read Customer Testimonials on the Manufacturer’s WebsiteWhile reviews on third-party sites are valuable, manufacturers often provide their own testimonials from satisfied customers. These can be a bit biased, but they still offer a glimpse into the customer experience. Look for a variety of experiences and check if the manufacturer addresses any concerns or issues promptly.

Gather Information from Trade Publications and Industry AwardsTrade publications in the appliance industry often highlight top-performing manufacturers. Additionally, awards and recognitions from reputable organizations can indicate a manufacturer’s standing in the industry. Look for accolades like “Best in Class” or “Innovative Design” that speak to the manufacturer’s commitment to quality.

Analyze the Manufacturer’s Online PresenceA manufacturer’s website can tell you a lot about their business practices. A well-maintained site with clear, professional information suggests a company that takes pride in its products. Conversely, a site that’s difficult to navigate, outdated, or filled with errors might be a red flag.

Explore Online Marketplaces and E-commerce PlatformsWebsites like Amazon, eBay, and Wayfair have customer review sections where buyers leave detailed feedback. These reviews can be particularly insightful as they come from people who have already purchased and used the product. Look for patterns in the feedback regarding the air fryer’s performance, build quality, and customer service.

Engage with the Manufacturer DirectlyIf you have the opportunity, reach out to the manufacturer directly. Ask about their quality control processes, manufacturing standards, and customer support policies. A responsive and informative interaction can give you a sense of the company’s commitment to customer satisfaction.

Look for Testimonials from Distributors and RetailersDistributors and retailers often have a close relationship with manufacturers and can provide insights into their reliability. Reach out to them if possible and ask about their experience with the manufacturer. They may share valuable information about the quality of the products and the level of support they receive.

Consider Industry Trends and NewsStaying updated on industry trends and news can also provide clues about a manufacturer’s reputation. Articles about new technologies, recalls, or technological breakthroughs can give you an idea of where a manufacturer stands in the market.

Beware of Fake Reviews and TestimonialsWith the rise of fake reviews, it’s important to be skeptical. Look for consistency in the feedback, and cross-reference the information with other sources. If something seems too good to be true, it might be a case of misinformation or manipulation.

By thoroughly researching a manufacturer’s industry reputation and reviews, you can gain a comprehensive understanding of their track record and make a more informed decision when selecting an air fryer manufacturer. Remember, the best air fryer is only as good as the company that makes it.

Understanding the quality of an air fryer manufacturer’s products is crucial for making an informed decision. Here’s a breakdown of the key aspects to consider:

Material Selection: The foundation of a quality air fryer lies in the materials used. Top manufacturers prioritize durable, food-grade materials that not only ensure safety but also longevity. Look for stainless steel, high-quality plastics, and non-stick coatings that are free from harmful chemicals.

Design and Engineering: A well-engineered air fryer is not just about looks; it’s about functionality and efficiency. Pay attention to the design elements such as even heat distribution, user-friendly controls, and the ability to handle various cooking tasks. The design should also cater to ease of cleaning and maintenance.

Performance Metrics: When evaluating product quality, consider the performance metrics such as cooking capacity, temperature control, and energy efficiency. A reliable air fryer should be able to cook a variety of foods with precision, reaching the desired temperature consistently. It should also consume energy efficiently, reducing utility bills.

Testing and Certification: Quality air fryer manufacturers often undergo rigorous testing to ensure their products meet international standards. Look for certifications from reputable organizations like the Underwriters Laboratories (UL), the European Committee for Electrotechnical Standardization (CENELEC), or the Food and Drug Administration (FDA). These certifications are a testament to the product’s safety and quality.

User Feedback: Customer reviews and testimonials can provide invaluable insights into the real-world performance of air fryers. Check out online forums, social media, and review sites to see what users are saying about the durability, ease of use, and overall satisfaction with the products from the manufacturer in question.

Warranty and Customer Service: A strong warranty policy reflects a manufacturer’s confidence in their product’s quality. A reliable air fryer should come with a comprehensive warranty that covers both parts and labor. Additionally, the manufacturer should offer responsive customer service, ready to assist with any issues or questions that may arise.

Innovation and Continuous Improvement: A quality manufacturer is always looking to innovate and improve their products. Look for signs that the company invests in research and development, introducing new features or technologies that enhance the air fryer’s performance and user experience.

After-Sales Support: The support a manufacturer provides after the sale is a good indicator of their commitment to quality. This includes easy access to replacement parts, clear instructions for use, and a helpful customer service team that can guide you through any troubleshooting.

Comparative Analysis: To truly evaluate product quality, it’s beneficial to compare the air fryers from different manufacturers. Look at the specifications, features, and prices to see where the manufacturer stands in the market. Sometimes, a higher price tag can be justified by superior quality and performance.

Longevity and Reliability: A quality air fryer is not just about the initial purchase; it’s about the long-term experience. Check for reviews that mention how long the product has been in use and whether users have encountered any issues. A product that has stood the test of time is a good sign of its reliability.

By carefully considering these aspects, you can gain a comprehensive understanding of an air fryer manufacturer’s product quality standards, ensuring that you invest in a product that will meet your expectations and last for years to come.

When it comes to selecting a reliable air fryer factory, one crucial aspect you cannot overlook is the checking of certifications and compliance. This step ensures that the products you source meet the highest standards of safety, quality, and environmental responsibility. Here’s what you need to know:

Understanding Certification ImportanceCertifications are like a seal of approval, vouching for the air fryer factory’s adherence to specific industry standards. They serve as a benchmark for quality assurance and often reflect the company’s commitment to excellence.

Common Certifications to Look ForSeveral certifications are widely recognized in the industry, each with its own set of stringent requirements. These include but are not limited to:

Verifying Certification AuthenticityOnce you’ve identified the relevant certifications, it’s essential to verify their authenticity. This can be done by:

Assessing Compliance with International StandardsCompliance extends beyond certifications to the adherence to international standards. This includes:

Understanding Country-Specific RegulationsDifferent countries have their own set of regulations and standards that must be adhered to. For example:

The Impact of Non-ComplianceFailing to comply with certifications and regulations can have severe consequences. Not only does it risk the safety of consumers, but it can also lead to fines, recalls, and damage to the company’s reputation. It’s important to ensure that the air fryer factory you choose is committed to compliance to avoid these pitfalls.

ConclusionIn conclusion, checking certifications and compliance is a critical step in selecting a reliable air fryer factory. It not only guarantees the quality and safety of the products but also reflects the company’s dedication to ethical and sustainable practices. By thoroughly investigating these aspects, you can be confident in your choice and the products you bring to market.

Understanding the intricacies of a factory’s facilities and equipment is crucial when seeking a reliable air fryer manufacturer. Here’s what to look for:

The Layout and Organization of the Factory: A well-organized factory is a sign of efficiency. Observe how the workspace is divided, ensuring that there’s a clear flow of materials and products. Look for designated areas for different stages of production, such as raw material storage, assembly lines, and quality control.

State-of-the-Art Manufacturing Equipment: Modern, advanced machinery is indicative of a manufacturer’s commitment to quality. Check if the factory uses automated systems for precision and consistency. High-tech equipment can also reduce the likelihood of human error.

Cleanliness and Hygiene: A clean factory is not just about aesthetics; it’s a reflection of the manufacturer’s dedication to health and safety standards. Inspect the cleanliness of the floors, machinery, and the air in the factory. Look for regular cleaning schedules and protocols to maintain a hygienic environment.

Quality Control Measures: The presence of a robust quality control department is a must. Observe how products are tested and inspected at various stages of production. Look for signs of thorough testing, including product functionality, safety, and durability checks.

Safety Regulations: A reliable factory adheres to stringent safety regulations. Check for safety signs, emergency exits, and protective gear for employees. Safety should be a top priority, and this is evident in the factory’s layout and operational procedures.

Material Handling and Storage: Efficient material handling is key to maintaining quality. Observe how raw materials are stored and transported within the factory. Proper storage conditions, such as temperature and humidity control, are crucial for preserving the integrity of the materials.

Training and Development: The factory should invest in training its employees to ensure they are knowledgeable about the products and the manufacturing process. Look for signs of ongoing training programs and employee development opportunities.

Energy Efficiency: A forward-thinking manufacturer may also prioritize energy efficiency. Check if the factory uses energy-saving technologies and practices. This not only reduces costs but also demonstrates a commitment to sustainability.

Waste Management: Responsible waste management is essential for environmental protection. Observe how the factory handles and disposes of waste. Look for recycling programs and initiatives to minimize environmental impact.

Product Variety and Customization: A versatile factory that can handle a range of products and customization requests is likely to be more reliable. Assess their ability to cater to different specifications and requirements.

Customer Support and Service: The factory’s approach to customer support can provide insight into their commitment to quality. Check if they offer after-sales service and how they handle customer inquiries and feedback.

Certifications and Standards: Finally, look for certifications that the factory holds, such as ISO standards, which demonstrate adherence to international quality management systems.

By thoroughly inspecting these aspects of a factory’s facilities and equipment, you can gain a clearer picture of the manufacturer’s commitment to quality and reliability in producing air fryers.

When looking for a reliable air fryer factory, one crucial aspect to consider is their ability to offer customization and innovation. This not only ensures that you get a product that meets your specific needs but also indicates the factory’s commitment to staying ahead in the competitive kitchen appliances market. Here’s a deeper dive into what to look for in a factory’s customization and innovation capabilities:

Tailored Product Offerings: A factory with strong customization capabilities should be able to provide a range of air fryers that can be tailored to your exact specifications. This could mean adjusting the size, capacity, and features of the appliance to fit your brand or target market. From a sleek design to advanced cooking functions, the factory should be flexible in adapting the product to your vision.

Innovative Technology Integration: The factory should be at the forefront of incorporating new technologies into their air fryers. This might involve using the latest materials for better heat retention and durability, or integrating smart features that enhance the user experience. Look for a factory that is continuously researching and developing new technologies to improve their product line.

Design Flexibility: A quality air fryer factory will offer design flexibility, allowing you to choose from a variety of aesthetic options. This could include different colors, finishes, and even custom branding. The ability to create a unique product that stands out on the shelf is a testament to the factory’s design capabilities.

Custom Features and Add-Ons: The best factories are those that can offer additional features or accessories that can be added to the base model of the air fryer. This could include temperature control systems, unique cooking baskets, or even modular components that allow for easy upgrades or replacements.

Prototyping and Development Process: A factory that prides itself on customization should have a robust prototyping and development process. This means they can create a working model of your air fryer quickly and efficiently, allowing you to test and refine the design before mass production.

Collaborative Approach: The factory should be open to collaboration, working closely with you to understand your needs and provide solutions. This might involve regular meetings, feedback sessions, and iterative design changes to ensure the final product aligns with your expectations.

Quality Control During Customization: Customization doesn’t mean compromising on quality. A reliable factory will maintain strict quality control measures throughout the customization process. This includes ensuring that all custom parts meet the same high standards as the standard components.

Innovation in Material Usage: A factory that values innovation will be exploring new materials and manufacturing techniques. This could mean using sustainable materials, lightweight yet robust components, or exploring the use of 3D printing for custom parts.

Adaptability to Market Trends: The ability to adapt to changing market trends is crucial. A factory with a strong innovation team will be able to quickly respond to new consumer demands and incorporate these into their product offerings.

Long-Term Relationship Building: A factory that invests in customization and innovation is likely to be invested in building a long-term relationship with you. This means they will be more willing to support you with ongoing product improvements and updates.

By assessing these aspects, you can gain a clearer picture of a factory’s customization and innovation capabilities. This will help you determine if they are the right partner to bring your vision of an exceptional air fryer to life. Remember, a factory that is committed to both customization and innovation is not just producing a product; they are creating a story—a story of quality, uniqueness, and forward-thinking.

Navigating through the vast array of air fryer manufacturers, it’s crucial to find a partner that not only meets your production needs but also aligns with your brand’s values and customer expectations. To achieve this, seeking recommendations and networking can be pivotal in identifying a reliable and innovative air fryer factory. Here’s how you can tap into this valuable process:

Engaging with the Industry CommunityNetworking within the industry is a powerful way to uncover hidden gems and gain insights into the best air fryer manufacturers. By participating in trade shows, industry forums, and online communities, you can connect with fellow professionals who have firsthand experience with various manufacturers. These connections can provide invaluable recommendations based on real-world interactions and experiences.

Trade Show ShowcasingTrade shows are a treasure trove of opportunities for discovering reputable air fryer factories. These events bring together a wide range of manufacturers, showcasing their latest products and technologies. Take the time to walk the aisles, attend workshops, and engage in discussions with representatives from different companies. Look for those who are eager to share details about their production capabilities, quality control measures, and innovation processes.

Online Reviews and ForumsThe digital world is a vast marketplace for reviews and forums. Platforms like Alibaba, Manta, and specialized trade forums offer a wealth of information about various air fryer manufacturers. Dive into the reviews section to see what other buyers have to say about their products and services. Pay attention to both positive and negative feedback to get a well-rounded understanding of each factory’s reputation.

Leveraging Social MediaSocial media platforms can be surprisingly useful for networking and gathering information about air fryer manufacturers. Follow industry leaders, join relevant groups, and engage in conversations. Manufacturers often showcase their products and share updates on their social media channels, giving you a glimpse into their operations and customer service.

Referrals from Established BrandsEstablished brands within the air fryer industry are a great source of referrals. Reach out to these brands and ask for recommendations based on their experiences with different manufacturers. Established brands often have stringent quality standards and will likely recommend factories that meet or exceed those expectations.

Consulting Distributors and RetailersDistributors and retailers who specialize in kitchen appliances are in a unique position to offer insights into the reliability of air fryer manufacturers. They work closely with a variety of factories and can provide you with information on which manufacturers are most consistent with their product quality and delivery times. Their relationships with these factories can also lead to special deals or exclusive partnerships.

Joining Industry AssociationsBecoming a member of industry associations can open doors to networking opportunities with air fryer manufacturers. Associations often host events, webinars, and conferences that bring together manufacturers, distributors, and retailers. These events are not only a chance to network but also to learn about the latest trends and standards in the industry.

Participating in Industry RoundtablesRoundtables and panel discussions provide an excellent opportunity to learn from industry experts and ask direct questions about air fryer manufacturers. These gatherings can be found at various industry events and are a great way to gain insights into the nuances of working with different factories.

Seeking Out TestimonialsRequesting and reviewing testimonials from potential manufacturers can be enlightening. Look for manufacturers with a strong track record of delivering high-quality air fryers and providing excellent customer service. Testimonials can often be found on the manufacturer’s website or through third-party review sites.

By engaging in these networking and recommendation-seeking activities, you can build a strong network of contacts who can guide you towards the most reliable and innovative air fryer factories. Remember, the right connections can be the key to a successful partnership that will not only meet your production needs but also enhance your brand’s reputation in the market.

Understanding the pricing and lead times from different air fryer manufacturers is crucial for making an informed decision. Here’s how to navigate this process effectively:

Gather Multiple Quotes: It’s essential to collect quotes from various suppliers to get a comprehensive understanding of the market. Don’t just settle for one or two options; the more quotes you have, the better your chances of finding a competitive price and suitable terms.

Analyze Pricing Structure: Look closely at how each manufacturer structures their quotes. Are they offering a flat rate, or do they have tiered pricing based on volume? Understanding this can help you negotiate better deals and identify potential cost-saving opportunities.

Consider Volume Discounts: If you’re planning to purchase a large quantity of air fryers, it’s worth exploring volume discounts. Some manufacturers offer reduced prices for bulk orders, which can significantly impact your overall cost.

Factor in Lead Times: The time it takes for a manufacturer to produce and deliver your order, known as lead time, is a critical factor. Compare lead times across different suppliers to ensure you’re getting the best balance between cost and delivery speed. Longer lead times might mean lower prices, but they could also delay your project or product launch.

Check for Hidden Costs: Sometimes, the initial quote may not include all the expenses associated with the order. Be vigilant about any additional fees, such as shipping, customs duties, or packaging costs. These can add up and impact your overall budget.

Review Payment Terms: Different manufacturers may have varying payment terms. Some might require a large upfront payment, while others might offer more flexible payment plans. Assess which payment structure aligns best with your financial strategy.

Look for Long-Term Partnerships: If you anticipate a continued relationship with the manufacturer, consider the long-term implications of their pricing and lead times. A supplier who offers competitive rates and shorter lead times may be more valuable in the long run.

Evaluate the Supplier’s Reputation: A manufacturer with a strong reputation for reliability and customer service is likely to deliver on their promises regarding quotes and lead times. Check reviews and testimonials to gauge their track record.

Negotiate When Necessary: Don’t be afraid to negotiate if you find that the quotes and lead times are not meeting your requirements. Use your research to highlight areas where you can secure a better deal, whether it’s through volume discounts, faster delivery, or other incentives.

Keep Communication Open: Throughout the negotiation process, maintain open lines of communication with the manufacturer. This ensures that any concerns or changes in requirements are addressed promptly and accurately.

Document Everything: Make sure to document all quotes, negotiations, and agreements in writing. This serves as a reference point and can be invaluable in resolving any disputes or misunderstandings that may arise later.

Consider the Total Cost of Ownership: When comparing quotes and lead times, also consider the total cost of ownership. This includes not only the initial purchase price but also any ongoing costs, such as maintenance, repairs, and energy consumption.

Plan for Contingencies: Always have a contingency plan in place. If a supplier’s lead time is longer than expected, or if prices change, you’ll need a strategy to adapt without compromising your project’s timeline or budget.

Stay Informed: Keep up-to-date with market trends and changes in the industry. This knowledge can help you anticipate potential price fluctuations and adjust your strategy accordingly.

Make an Informed Decision: After carefully comparing quotes and lead times, weigh all the factors to make the best decision for your business. Remember that the cheapest quote isn’t always the best choice if it comes with significant risks or drawbacks.

By thoroughly examining the quotes and lead times from different air fryer manufacturers, you can ensure that you’re getting the best value for your investment and that your business’s needs are met efficiently and effectively.

Navigating through the final stages of a deal with a reliable air fryer factory requires a careful balance of expectations, negotiation, and trust. Here’s how to ensure that the partnership is solid and the agreement is beneficial for both parties:

Understanding the Contract DetailsBefore signing on the dotted line, it’s crucial to dive deep into the contract. Look for clauses that outline delivery schedules, payment terms, and any penalties for late deliveries or non-compliance. Make sure the contract reflects your needs and the factory’s capabilities.

Negotiating the TermsOnce you have a clear understanding of the contract, it’s time to negotiate. Don’t be afraid to ask for adjustments that better suit your business model. Whether it’s the price, minimum order quantity, or delivery frequency, be prepared to advocate for what you believe is fair and beneficial for your venture.

Verifying the Factory’s CapabilitiesBefore finalizing the deal, it’s essential to have a concrete understanding of the factory’s capacity to meet your demands. This includes assessing their production volume, the ability to scale up or down based on your needs, and their track record with similar orders. A factory that can consistently deliver high-quality products on time is a valuable asset.

Reviewing the Factory’s Track RecordA factory’s history speaks volumes about its reliability. Look for evidence of past successful collaborations, particularly with clients who have similar business profiles. Check for testimonials, case studies, or references that can vouch for the factory’s performance. This due diligence can prevent costly mistakes and ensure a smooth partnership.

Addressing Intellectual Property ConcernsIf your air fryer designs or branding are proprietary, ensure that the contract clearly outlines intellectual property rights. This includes specifying how your designs will be protected and used by the factory. Avoid any ambiguity that could lead to disputes down the line.

Clarifying Post-Sales SupportA reliable factory should offer post-sales support, including maintenance, repairs, and replacements. Ensure that these terms are explicitly stated in the contract. This support can be crucial for maintaining customer satisfaction and the reputation of your brand.

Establishing Communication ProtocolsEffective communication is key to a successful partnership. Define how you and the factory will communicate, including the frequency of updates, the preferred method of contact, and the roles and responsibilities of each party. This clarity can prevent misunderstandings and ensure that both sides are aligned.

Reviewing Legal and Financial AspectsLegal and financial aspects should not be overlooked. Ensure that all legal compliance is met, including any export or import regulations that may apply. Also, review the financial terms, such as payment schedules and dispute resolution mechanisms. A clear understanding of these details can prevent financial and legal issues in the future.

Finalizing the ContractOnce all the above points have been thoroughly discussed and agreed upon, it’s time to finalize the contract. Both parties should review the document carefully and, if necessary, seek legal advice to ensure that the contract is watertight.

Securing the Deposit or Payment ScheduleBefore the factory begins production, secure the necessary deposit or set up a payment schedule. This helps to ensure that the factory is committed to the project and provides a level of financial security for both parties.

Monitoring the Production ProcessEven after the contract is signed, it’s important to keep an eye on the production process. Regular updates and progress reports can help you stay informed and address any issues promptly.

Upon CompletionOnce the air fryers are produced and delivered, inspect the goods to ensure they meet the agreed-upon quality standards. If everything is in order, you can proceed with the final payment and establish a plan for future orders or collaborations.

In conclusion, finalizing a deal with a reliable air fryer factory is a multi-faceted process that involves careful planning, negotiation, and due diligence. By paying attention to contract details, factory capabilities, intellectual property, communication, and legal and financial aspects, you can set the stage for a successful and long-lasting partnership.