Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

With the growing call for for personalized kitchen home equipment from purchasers, the custom designed touch grilling OEM marketplace is experiencing a lively increase. this article will delve into this field and discover how to gain a value discount of up to 30% thru innovative techniques and realistic implementations. precise case studies may be offered to investigate the application and effectiveness of this modern model in the market.

The upward thrust of customizable contact grills in the OEM (authentic device manufacturer) sector is a trend that has regularly emerged with the non-stop improvement of the current kitchen equipment marketplace and the diversification of customer wishes. This emergence now not simplest reflects the marketplace’s demand for customization and useful innovation but also exhibits a brand new growth factor within the kitchen equipment industry.

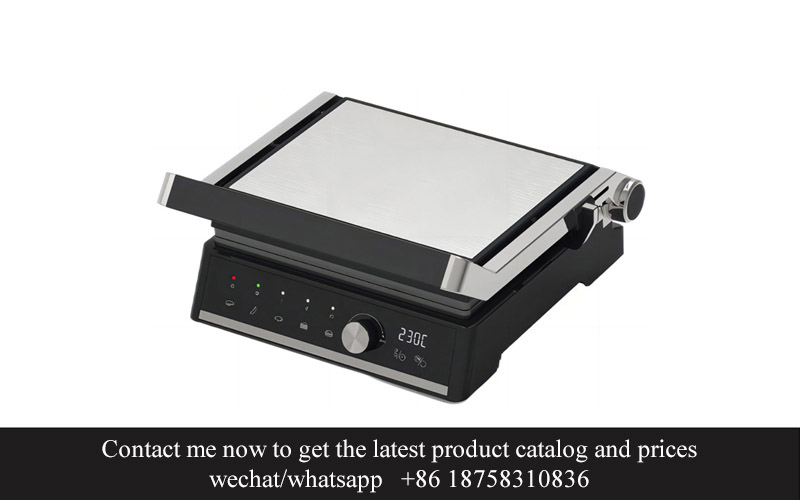

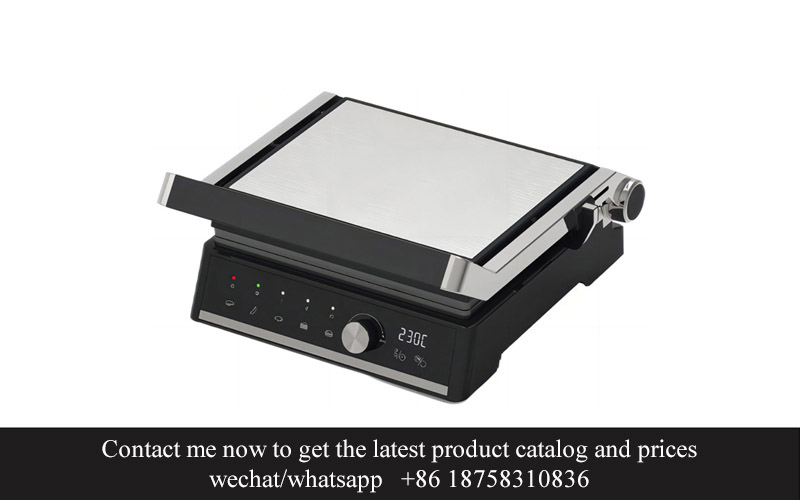

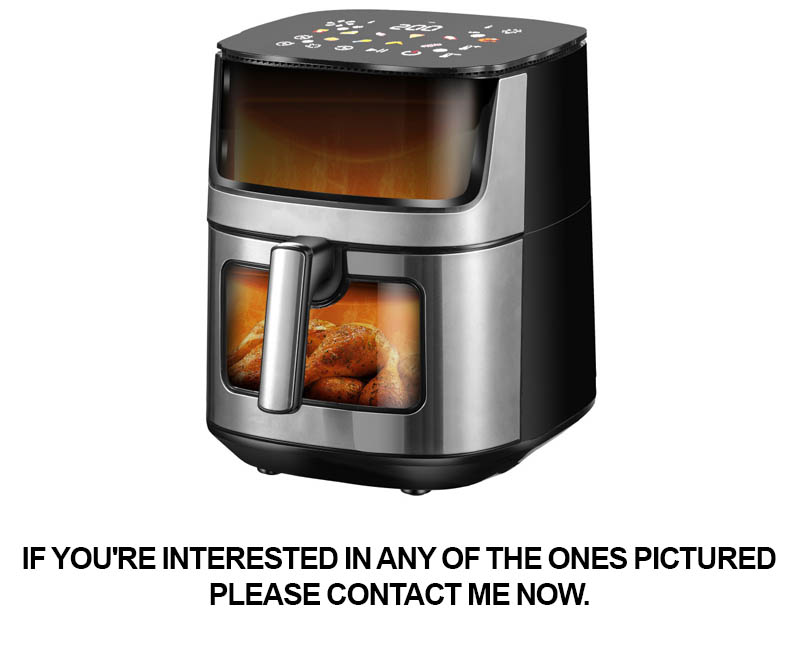

On one hand, consumers’ expectations for kitchen appliances have shifted from basic features to personalized reviews. Customizable contact grills cater to one of a kind customers’ wishes for cooking techniques by means of imparting a variety of sizes, shapes, and functionalities. From household kitchenware to business kitchen gadget, customizable grills can adapt to diverse cooking eventualities which include barbeque, grilling, and meat roasting, allowing OEM manufacturers to customize their products in line with particular purchaser requirements, thereby enhancing product competitiveness.

then again, the catering industry’s demand for professionalization and efficiency is increasing. Customizable touch grills stand out in this discipline, not best assembly numerous cooking desires however additionally enhancing kitchen efficiency through precise temperature manipulate and rapid heating talents. With the proliferation of food delivery offerings and the intensification of opposition in the catering enterprise, rapid, green, and multifunctional kitchen home equipment have end up key to enhancing purchaser satisfaction and provider speed.

the improved cognizance of environmental protection has additionally driven the upward thrust of customizable touch grills. conventional grill gadget often has high energy intake, whilst customized grills can reduce energy intake via optimized design and decrease carbon emissions. within the context of power conservation and emission discount, OEM manufacturers are launching power-saving custom designed grills, which now not only follow the idea of inexperienced improvement however also meet the marketplace demand for environmentally pleasant products.

In terms of technological innovation, customizable touch grills are beginning to integrate internet of things (IoT) and big facts technology, permitting precise control over the cooking process with features together with smart temperature manage and far off tracking. This trend of intelligence no longer only improves the product’s user revel in however also brings new marketplace possibilities for OEM manufacturers.

With the maturation of the marketplace and the advancement of technology, the deliver chain for customizable contact grills is likewise constantly enhancing. From uncooked material procurement to manufacturing and processing, and ultimately to logistics distribution, the overall deliver chain performance has significantly accelerated. This not simplest reduces manufacturing fees however also shortens the time to marketplace for products, enabling OEM manufacturers to reply more fast to market changes.

The rise of customizable contact grill OEM is the result of multiple factors running collectively. From fulfilling patron personalized desires to enhancing performance inside the catering enterprise, to upholding the concept of environmental safety, this trend surely brings new vitality and possibilities to the kitchen appliance enterprise. As era continues to evolve and marketplace demand maintains to develop, the market potential of customizable touch grills is predicted to be further unleashed.

achieving a 30% fee reduction within the kitchen equipment enterprise, especially inside the touch-kind baking plate region, is not an easy undertaking. but, by enforcing the following techniques, organizations can substantially decrease charges whilst preserving product nice:

deliver Chain Integration and Optimizationby integrating the supply chain, businesses can lessen intermediate links, establish direct partnerships with uncooked fabric suppliers, and lower procurement charges. additionally, thru bulk shopping and long-time period agreements, extra favorable prices can be received. furthermore, optimizing the deliver chain to put off needless links can reduce logistics and warehousing costs.

layout Innovation and Simplificationduring the design phase, simplifying the shape and lowering the number of components can lower manufacturing charges. Adopting modular layout makes the manufacturing manner greater standardized, facilitating mass manufacturing, and reducing reliance on complex meeting techniques. moreover, introducing new substances and procedures can lessen the burden of the product with out compromising performance, thereby lowering cloth costs.

Automation of manufacturing proceduresAutomation in manufacturing can substantially enhance efficiency and decrease hard work prices. via introducing computerized gadget together with robot welding and automated assembly lines, dependency on hard work can be decreased, and defects and rework as a result of human errors can be minimized. at the same time, computerized manufacturing allows in real-time monitoring and analysis of production information, taking into account well timed modifications to manufacturing processes and lowering strength intake.

strength controlenergy prices account for a widespread component in kitchen appliance production. with the aid of enforcing energy-saving measures along with the usage of high-performance strength-saving system, optimizing production layouts to reduce strength waste, and conducting strength audits, electricity charges can be notably reduced. for example, replacing conventional fluorescent lights with LED lights, the usage of variable-frequency drives, and so forth.

Lean production and continuous improvementthe tilt manufacturing philosophy emphasizes waste elimination and performance development. by continuously improving manufacturing techniques, waste in production may be reduced, which includes lowering inventory, shortening production cycles, and decreasing disorder costs. furthermore, via establishing a lifestyle of continuous improvement, encouraging employees to suggest pointers for improvement, production techniques may be continuously optimized.

nice control and Preventive preservationStrict first-class control can reduce expenses caused by pleasant troubles, along with rework and waste. implementing a preventive preservation plan guarantees the solid operation of manufacturing gadget, decreasing downtime losses because of system failure.

Human resource OptimizationOptimizing human useful resource allocation, moderately dispensing paintings obligations, and improving employee efficiency. by using training to enhance employee abilities, mistakes and transform caused by talent deficiencies can be reduced. moreover, via performance appraisal and incentive mechanisms, employees’ paintings enthusiasm may be stimulated, improving average manufacturing efficiency.

by way of implementing these techniques, kitchen appliance agencies can attain a 30% value reduction whilst maintaining product pleasant, enhancing market competitiveness. however, these strategies require businesses to plan and execute comprehensively from a strategic angle.

inside the custom designed contact grilling plate OEM market, the aggregate of innovation and exercise is the important thing to driving cost discount. right here is an analysis of the way a agency that specialize in custom designed grilling plate production has executed a 30% value savings thru progressive techniques.

cloth Innovation: with the aid of growing new substances to update traditional materials, the corporation has effectively reduced the production charges of grilling plates. for example, the unique pure chrome steel grilling plates were highly-priced, proscribing the product’s marketplace competitiveness. by means of adopting new alloy substances, the corporation has maintained correct thermal conductivity at the same time as significantly reducing material costs, making the grilling plates more charge competitive in the market.

layout Optimization: The organisation has custom designed various forms of grilling plates to satisfy specific patron needs. by way of optimizing the internal structure and simplifying the manufacturing system, the organisation has decreased production expenses. as an example, a household grilling plate has been progressed by way of rational format of heating factors and cloth choice, which no longer most effective increases grilling efficiency however also reduces strength consumption, thereby decreasing production expenses.

three. automated production Line: The creation of automatic production system has expanded manufacturing efficiency and decreased exertions costs. throughout the grilling plate production system, the business enterprise has hired computerized welding, reducing, and sharpening equipment, significantly boosting manufacturing pace at the same time as reducing the mistake fee in guide operations.

four. Precision management: through the precision control of the production manner, the enterprise has executed powerful fee control. for instance, strict manage is maintained over raw material procurement, stock management, and manufacturing scheduling, reducing waste and losses.

deliver Chain Integration: by means of establishing long-term and stable partnerships with suppliers, the organization has secured favorable cloth prices. additionally, with the aid of integrating the deliver chain, logistics expenses are decreased, in addition enhancing product competitiveness.

training and Incentives: personnel are educated to enhance manufacturing performance. furthermore, via performance appraisal and incentive mechanisms, the business enterprise stimulates employee motivation, reducing labor fees.

high-quality manage: at the same time as ensuring product fine, the company optimizes the production system to reduce the price of transform. This guarantees customer pleasure and decreases additional expenses incurred because of great troubles.

marketplace studies: to fulfill marketplace call for, the agency constantly adjusts its product approach to meet customer needs. via studying marketplace statistics, the company adjusts manufacturing plans in a timely way, averting product backlog and capital career.

through those innovative techniques and practices, the customized contact grilling plate OEM business enterprise has carried out a 30% cost discount even as keeping product nice. this example demonstrates that in the fierce market opposition, through modern wondering and precision management, a company can preserve product competitiveness whilst reaching sustainable improvement.