Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

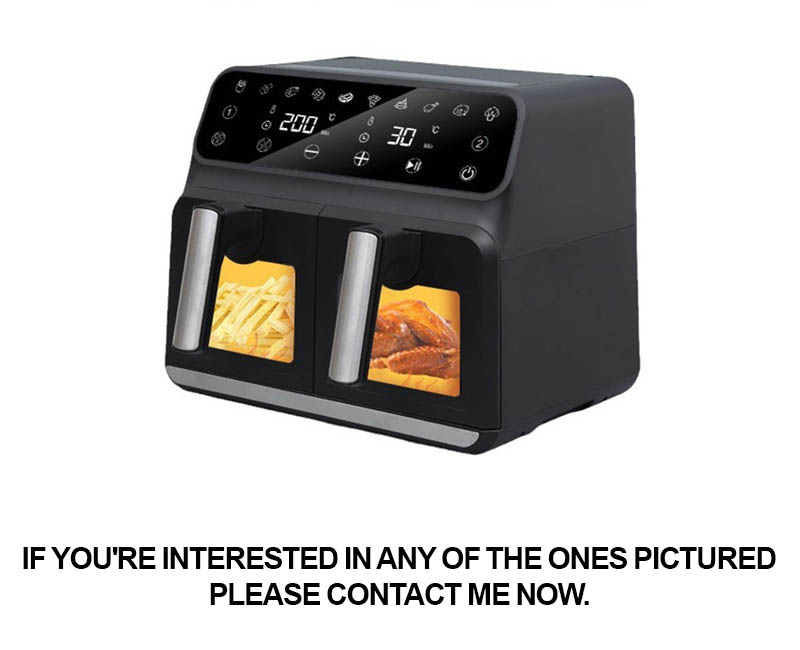

inside the eu and American kitchen appliance marketplace, a strain casting baking pan gadget that blends modern technology with wonderful craftsmanship is capturing the eye of purchasers with its particular allure. As a pacesetter within the subject, the EAC emblem’s baking pan manufacturing line no longer most effective showcases technological innovation inside the industry but additionally performs a huge position in market improvement. this text will delve into the performance and developments of the EAC pressure casting baking pan in the european and American markets, revealing the data tale at the back of it.

EAC Die Casting Molding factory has installed itself as a benchmark for innovative production in the kitchen home equipment industry with its remarkable craftsmanship and advanced system. The manufacturing unit employs excessive-precision CNC machine equipment to ensure that every step within the mildew manufacturing technique meets global standards. From fabric selection to warmness treatment, and to precision machining, EAC Die Casting Molding manufacturing unit meticulously controls each detail to ensure that every product possesses first rate durability and accuracy.

The manufacturing facility houses a committed studies and development middle, that is staffed by way of a group of industry experts and younger designers. They constantly explore new substances and processes, devoted to making use of the state-of-the-art technologies to the production of kitchen appliances. EAC Die Casting Molding manufacturing unit not handiest specializes in the performance of the product itself but also can pay close interest to consumer revel in, making kitchen home equipment greater shrewd and convenient through layout.

In terms of production procedures, EAC Die Casting Molding manufacturing unit implements a comprehensive best management device. From the advent of raw materials to the delivery of finished merchandise, each system is strictly inspected at fine checkpoints. The utility of automatic detection system guarantees that products can resist rigorous checking out before leaving the factory, making certain their stability and reliability. moreover, the manufacturing facility actively participates within the formula of international requirements, setting a brand new first-class benchmark for the global kitchen home equipment enterprise.

The progressive production capabilities of EAC Die Casting Molding manufacturing facility are not only meditated in the goods but additionally within the offerings provided. The manufacturing unit gives custom designed services, designing molds according to the specific wishes of clients to meet the special necessities of various markets. From market studies to product development, to mass manufacturing, EAC Die Casting Molding manufacturing unit works closely with customers to at the same time sell the entire procedure from layout to market.

In terms of environmental protection, EAC Die Casting Molding factory is also at the leading edge of the enterprise. The factory has introduced advanced environmental safety device to strictly manage the emission of waste all through the production process, reaching inexperienced production. additionally, the manufacturing facility actively promotes the idea of sustainable development, encouraging personnel to take part in power conservation and emission discount, contributing to the construction of a harmonious ecological surroundings.

With its revolutionary spirit, first rate craftsmanship, and environmental attention, EAC Die Casting Molding factory plays a great function inside the kitchen home equipment industry. via continuous technological innovation and notable product exceptional, EAC Die Casting Molding manufacturing facility is main the kitchen home equipment enterprise towards even better stages.

The EAC baking gadget manufacturing line boasts a excessive diploma of automation, from the location of uncooked materials to the very last baking of the product, each step reflects technological innovation and first-rate craftsmanship. The baking machines on the production line are designed in a modular way, which helps brief substitute and improvements, ensuring the flexibility and adaptableness of the products.

within the production of the center components of the baking machines, the EAC factory employs unique die-casting generation to ensure the accuracy of the molds and the stability of the substances. This excessive-precision die-casting method results in a uniformly heated floor on the baking plate of the baking device, higher thermal efficiency, and consequently shorter baking instances, improving the excellent of the product.

In terms of intelligent manage at the manufacturing line, the EAC baking device has done complete automation from raw cloth detection to completed product inspection. The gadget can display key parameters which include temperature, humidity, and strain in real-time and robotically regulate the baking technique via algorithms, making sure that every baking device can continually produce baking merchandise. further, the manufacturing line is geared up with a fault analysis system which could speedy alert and prevent the system while an anomaly occurs, ensuring manufacturing protection.

to satisfy the needs of various markets and clients, the EAC manufacturing unit’s baking gadget production line can speedy modify the layout of the production line to obtain a bendy production mode of a couple of sorts and small batches. This bendy production technique not most effective improves manufacturing efficiency however also reduces stock charges.

In terms of nice manipulate, the EAC baking machine manufacturing line has followed a strict exceptional management machine. each baking device ought to go through more than one inspection approaches before leaving the manufacturing unit, inclusive of appearance assessments, practical exams, durability assessments, and so on., to make sure that the products meet worldwide standards. similarly, EAC additionally gives custom designed R&D services, designing and optimizing products in keeping with the specific needs of clients.

With the non-stop development of era, the EAC baking system manufacturing line is introducing more clever factors. for instance, thru the net of things technology, the overall performance facts of the baking machines may be uploaded to the cloud in actual-time, permitting manufacturers to remotely reveal and keep them. This shrewd provider now not only improves product overall performance but also offers clients with a more handy consumer experience.

via non-stop technological innovation, the EAC baking device manufacturing line has no longer only improved production performance but also driven marketplace development. inside the fierce marketplace competition, the EAC baking machine has received the agree with and reputation of customers with its , high-performance, and wise capabilities.

EAC’s Die Casting Pizza Oven has carried out good sized market share inside the ecu and American markets due to its notable performance and design. the following is a particular analysis of its overall performance and developments within the european and American markets:

constant increase in market percentage: in view that its launch, EAC’s Die Casting Pizza Oven has fast received purchaser choose with its solid great and diverse functionalities. in step with market research facts, the marketplace share of the EAC brand within the ecu pizza oven marketplace has been rising yr by way of year, especially in North the us and Europe, where EAC has turn out to be the top choice for consumers.

Technological Innovation main the trend: EAC constantly pursues technological innovation within the production of pizza ovens, such as the usage of advanced die casting era to make the ovens extra durable and easy to easy. furthermore, EAC has introduced clever manipulate systems that permit customers to remotely operate the oven through a mobile app, significantly improving person enjoy. those technological innovations now not only satisfy customers’ pursuit of existence however additionally drive the improvement of the whole kitchen appliance enterprise.

rich Product Line to satisfy extraordinary wishes: EAC caters to the numerous wishes of clients via providing a variety of die casting pizza oven products. From small home pizza ovens to massive potential business pizza ovens, EAC’s product line covers markets from non-public to corporate levels. This diverse product method allows EAC to preserve a role inside the exceptionally aggressive ecu market.

Environmental protection idea Deeply Rooted: With the growing awareness of environmental safety, EAC makes a speciality of power saving and emission discount within the production system of pizza ovens. as an instance, EAC’s pizza ovens use quite green and energy-saving heating factors to reduce strength consumption. additionally, EAC is dedicated to the usage of environmentally friendly materials, reducing the effect at the surroundings. This environmental protection concept resonates with the intake developments within the ecu and American markets, further improving EAC’s market competitiveness.

five. comprehensive After-sales service to bolster consumer believe: EAC acknowledges the importance of after-income carrier to the brand image and has installed a comprehensive after-sales carrier device in the european and American markets. From pre-income session to after-sales repair, EAC affords expert offerings. This thoughtful provider now not best resolves patron worries but also strengthens consumer agree with within the EAC brand.

In summary, EAC’s Die Casting Pizza Oven’s performance and trends inside the eu and American markets indicate that technological innovation, product diversification, environmental safety concept, complete service, and preserving up with marketplace developments are the key factors that have allowed EAC to face out inside the fierce marketplace competition.