Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

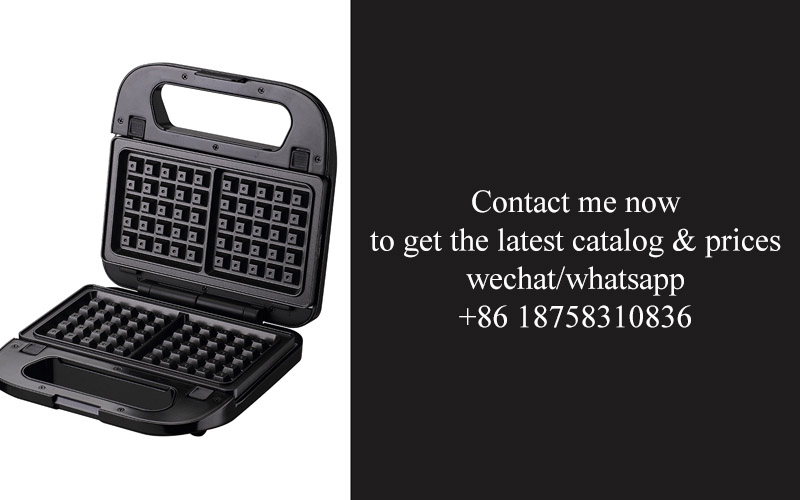

With the continuous enlargement of the global kitchen equipment marketplace, as a famous baking device, the solid aluminum wafer iron mold is experiencing a new wave of development possibilities inside the OEM market. this article will explore the synergy among marketplace demand for cast aluminum wafer iron molds and modern product design, as well as the improvement prospects of this discipline, primarily based on enterprise information.

The OEM market for forged aluminum wafer ironing boards is currently displaying the following principal traits:

Personalization Customization becoming the MainstreamAs clients’ demand for personalized kitchenware will increase, the marketplace for solid aluminum wafer ironing boards is step by step transferring in the direction of customization. OEM producers want to provide custom designed mold layout and production offerings in keeping with precise consumer necessities to fulfill the precise needs of different brands and purchasers.

** materials Gaining want**forged aluminum materials, because of their first-rate thermal conductivity, corrosion resistance, and durability, are getting the favored choice within the wafer ironing board OEM marketplace. With consumers’ growing health and protection necessities for food contact substances, solid aluminum molds have become the brand new preferred within the market.

three. smart production technology driving developmentThe software of wise manufacturing era inside the manufacturing of cast aluminum wafer ironing forums is regularly becoming sizeable. The introduction of automatic manufacturing strains has stepped forward manufacturing performance and product nice balance, whilst additionally lowering production costs. OEM manufacturers are enhancing their marketplace competitiveness through smart transformation.

four. logo Differentiation opposition Intensifiesinside the fierce marketplace opposition, logo differentiation has become a step forward factor for forged aluminum wafer ironing board OEM manufacturers. with the aid of technological innovation, product layout, and logo building, producers are growing merchandise with particular selling points to distinguish themselves from competition.

five. Environmental consciousness greaterWith the worldwide rise in environmental focus, OEM manufacturers are paying greater interest to the selection of environmentally pleasant materials and waste disposal in the production of forged aluminum wafer ironing boards. Environmental certification has end up an vital threshold for merchandise to enter the marketplace.

international market growth speeds upThe forged aluminum wafer ironing board OEM market is increasing globally. With the reduction of exchange boundaries and the growth of the global purchaser marketplace, home producers have the opportunity to export their products to diverse parts of the world, commencing up new marketplace areas.

fitness weight-reduction plan concept publications Product Innovationthe recognition of the fitness weight loss program idea has led clients to have higher requirements for the nice and protection of food. on this trend, OEM manufacturers are constantly introducing new wafer ironing board merchandise that meet fitness standards to satisfy consumers’ pursuit of a healthful lifestyle.

In precis, the OEM market for forged aluminum wafer ironing forums is driven by using multiple traits which include personalized customization, materials, intelligent production, brand differentiation, environmental focus, worldwide marketplace enlargement, and the health food regimen concept. producers need to keep up with marketplace trends, innovate and modify their strategies continuously to evolve to the ever-converting marketplace needs.

precisely grasp patron possibilities: within the kitchen appliance enterprise, consumers’ expectancies for products are no longer confined to simple features, but as a substitute attention on look layout, person revel in, and personalization. forged aluminum wafer iron molds, via OEM customization, can design wafer patterns and sizes that cater to nearby tastes in exclusive markets, pleasing purchasers’ pursuit of customized culinary reviews.

utility of materials: With the growing attention of environmental protection, clients are worrying better environmental overall performance from kitchen appliances. cast aluminum wafer iron molds are product of durable and easy-to-easy forged aluminum, which is also a recyclable fabric, aligning with the market’s demand for inexperienced and sustainable development.

three. bendy manufacturing Customization: The OEM model allows solid aluminum wafer iron molds to be custom designed in line with unique client necessities, whether or not it’s the shape, size, or sample of the mildew, assembly the diverse needs of the market for product range.

five. Optimization of person revel in: by constantly optimizing product structure and operation interface, forged aluminum wafer iron molds beautify consumer experience whilst ensuring cooking outcomes. for example, clean-to-put off mold designs and intuitive cooking commands make the product greater consumer-friendly.

brand Differentiation: within the fierce marketplace opposition, logo differentiation is the key to status out for organizations. cast aluminum wafer iron molds can create precise logo snap shots for clients via revolutionary design, improving the market competitiveness of the logo.

Integration of net advertising and marketing: With the prevalence of the internet, internet advertising has become an crucial promotional tool within the kitchen appliance industry. forged aluminum wafer iron molds can comprise elements of net advertising, together with QR code interactive scanning and social media sharing features, to boost product market interest.

In precis, the of modern product layout with market demand lies in carefully tracking patron traits, responding to environmental demands, offering customized offerings, specializing in power-saving design, optimizing consumer enjoy, attaining emblem differentiation, and integrating net advertising and marketing techniques. these factors together drive the improvement of forged aluminum wafer iron molds within the OEM market.

The development possibilities of forged aluminum wafer mildew plates within the OEM marketplace are supported by using numerous statistics. On one hand, the growing call for for fitness and personalized diets among customers is riding the pursuit of wafer plates; however, with the enlargement of the global kitchen appliance marketplace, cast aluminum wafer mold plates, as an crucial issue of kitchen appliances, maintain giant marketplace capability.

market research information display that during current years, the worldwide kitchen equipment market has continued to increase, with the sales of waffle makers growing yr by using 12 months. consumers are setting higher demands at the high-quality of wafer plates, no longer handiest for flavor however also for health and personalization. forged aluminum molds, with their specific properties inclusive of high-temperature resistance, non-stick surfaces, and ease of cleaning, have grow to be the desired cloth for wafer plate production.

From the angle of technological innovation, the layout of forged aluminum wafer mould plates has been constantly optimized to fulfill market demands. for instance, floor treatment technology for the molds has advanced the anti-stick performance of the wafer plates, even as innovative mould shapes have introduced approximately a greater variety of product forms. those technological innovations now not handiest enhance the market competitiveness of the goods however also provide OEM producers with extra customization services.

The upward push in environmental attention has additionally pushed the development of the cast aluminum wafer mould plate OEM market. As worldwide attention shifts to environmentally pleasant substances, cast aluminum molds, as recyclable and reusable substances, have received market recognition for his or her environmental attributes. enterprise reports suggest that the market percentage of environmentally friendly solid aluminum wafer mildew plates has been rising yr with the aid of year and is predicted to hold developing in the coming years.

From a deliver chain attitude, the improvement of the forged aluminum wafer mould plate OEM market is attributed to the of the global industrial chain. From raw material procurement, mold manufacturing, product assembly to logistics distribution, the adulthood of every link provides a robust guarantee for the production of solid aluminum wafer mould plates. at the identical time, with the application of intelligent manufacturing technology, manufacturing efficiency has been substantially progressed, further decreasing costs and enhancing the market competitiveness of the products.

From the angle of marketplace distribution, the cast aluminum wafer mildew plate OEM marketplace is showing a various fashion globally. The demand for excessive-quit wafer plates inside the ecu and American markets is growing step by step, whilst the Asian marketplace is experiencing speedy growth due to the more youthful purchaser shape. these market traits offer OEM manufacturers with wide improvement space and additionally require manufacturers to have the ability to quick reply to market adjustments.

In precis, the improvement possibilities of the cast aluminum wafer mold plate OEM marketplace are showed by way of industry statistics, and its market potential is good sized. manufacturers ought to seize this possibility to continuously enhance product first-class, give a boost to technological innovation, and meet the ever-changing marketplace demands.