Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

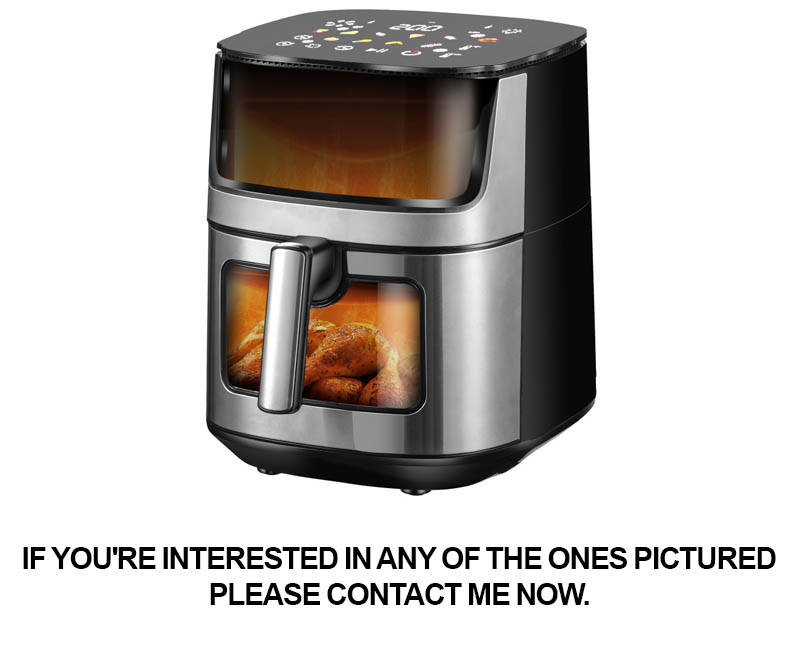

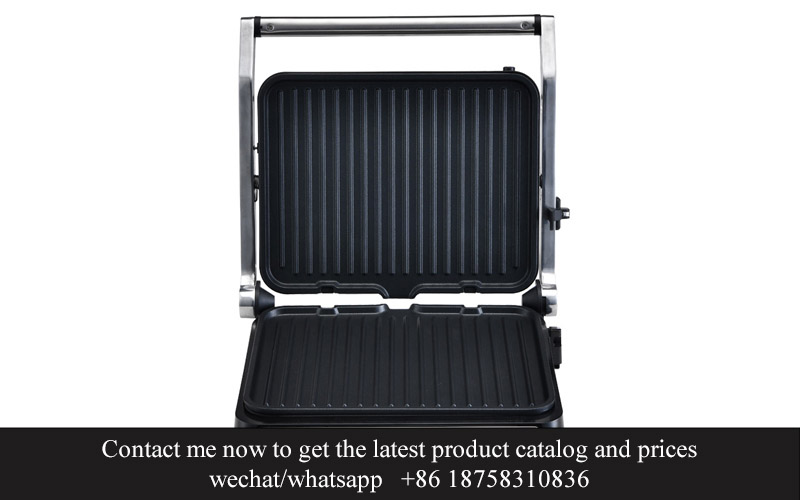

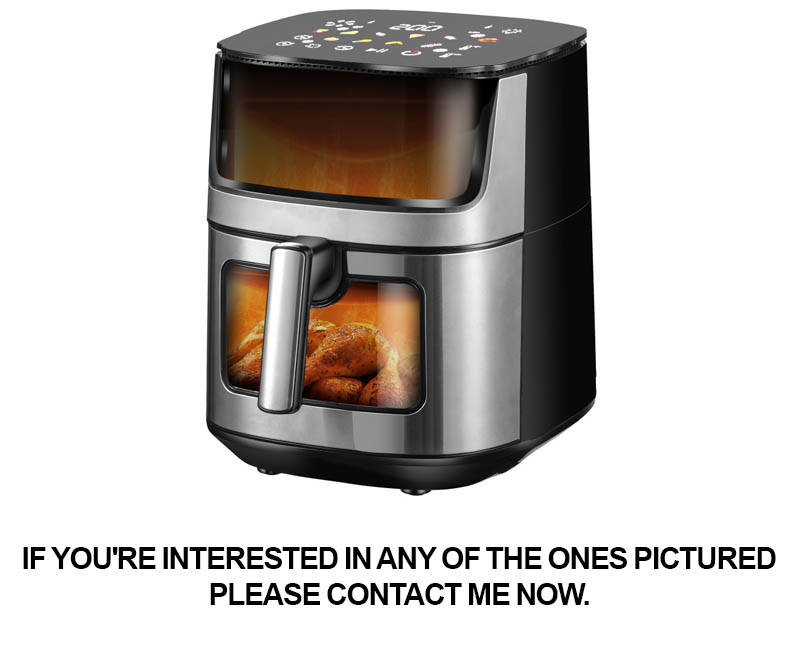

In today’s fast-paced world, the kitchen has evolved from a mere cooking space to a hub of culinary innovation. Among the myriad advancements, the air fryer has emerged as a game-changer, transforming the way we approach healthy and delicious cooking. As this appliance gains popularity, the manufacturing industry is also undergoing a remarkable transformation, driven by automation and cutting-edge technology. This article delves into the heart of the automated air fryer assembly line, exploring its efficiency, quality control, cost savings, safety, and the exciting future it promises for the kitchen appliance industry.

In the bustling heart of the modern kitchen appliance industry, the air fryer has emerged as a star product, offering a healthier alternative to traditional frying methods. This surge in popularity has led to the development of sophisticated assembly lines designed to meet the high demand for these versatile appliances. Let’s take a closer look at the marvel that is the air fryer assembly line.

The assembly line is a marvel of modern engineering, where precision and efficiency are paramount. It’s a testament to how far technology has come in transforming the way we produce everyday items. At the heart of this process is the air fryer, a compact kitchen gadget that has captured the hearts of health-conscious consumers and chefs alike.

The journey of the air fryer begins with raw materials—metals, plastics, and electronics—that are carefully selected for their quality and durability. These materials are then transported to the assembly line, where the transformation into a functional appliance begins.

The assembly line is a meticulously choreographed dance of robotics and human expertise. It starts with the unboxing and sorting of components, where each part is inspected for quality and compatibility. This initial step is crucial, as any defect can lead to a faulty final product.

Once sorted, the components move through a series of automated stations. The first stop is the frame assembly, where metal sheets are cut, bent, and together to form the air fryer’s body. The precision of these robotic welders is astonishing; they can complete intricate joints with a consistency that would be impossible for human hands.

Next comes the electrical assembly, where the heart of the air fryer—the heating element and fan—comes to life. Here, sensors and automated tools ensure that each component is perfectly positioned and securely fastened. The attention to detail is incredible; even the smallest gaps are filled with high-temperature resistant sealants to prevent any leaks.

As the air fryer’s body takes shape, it moves on to the exterior finishing stage. This is where the appliance gains its sleek and modern look. The plastic parts are molded and painted, with robotic arms applying a smooth, uniform finish. The colors and textures are selected to appeal to a wide range of consumers, from the minimalist to the bold.

Inside, the electronics are being carefully integrated. The control panel, buttons, and display are all meticulously installed, with each connection tested for functionality. The assembly line is equipped with high-tech diagnostic tools that can detect even the slightest anomaly, ensuring that only air fryers that meet the highest standards leave the line.

Once the internal components are in place, the air fryer is subjected to rigorous testing. It’s put through a series of cycles to simulate real-world use, including heating, cooling, and even overheating scenarios. This testing phase is critical, as it guarantees that the air fryer will perform reliably and safely in the hands of consumers.

After passing the tests, the air fryer moves on to the packaging station. Here, it’s carefully enclosed in protective materials, ready for transport to retail stores. The packaging process is automated to ensure that each unit is sealed properly, protecting it from damage during shipping.

The air fryer assembly line is not just about speed and efficiency; it’s also about sustainability. The line is designed to minimize waste, with recycling stations for materials like packaging and plastic components. The energy used by the line is carefully managed, with systems in place to reduce consumption and lower the environmental impact.

In conclusion, the air fryer assembly line is a marvel of modern manufacturing. It showcases the blend of advanced robotics, precise engineering, and human ingenuity that powers the kitchen appliance industry. As consumer demand continues to grow, the assembly line stands ready to deliver high-quality air fryers at an unprecedented pace, all while maintaining the highest standards of quality and safety.

In recent years, the kitchen appliance industry has undergone a remarkable transformation, with automation playing a pivotal role in this evolution. The adoption of automated systems has revolutionized the way appliances are manufactured, offering numerous benefits that extend beyond just efficiency and cost savings.

The automation of kitchen appliances has been driven by several key factors. Firstly, consumer demand for faster, more convenient, and technologically advanced products has skyrocketed. Modern consumers are no longer satisfied with basic functionalities; they seek smart features and seamless integration into their daily lives. This shift in consumer expectations has pushed manufacturers to innovate and automate their production processes to meet these demands.

Secondly, the rapid advancements in technology have made it possible to integrate sophisticated automation systems into the manufacturing of kitchen appliances. From robotics to AI-driven sensors, these technologies have enabled precise and consistent production, reducing the margin for human error and improving overall quality.

One of the most significant impacts of automation in kitchen appliances is the increase in efficiency. Manual assembly lines, once the norm, were prone to bottlenecks and inconsistencies. Automation has eliminated these issues by streamlining the production process. Robots and automated machines can work tirelessly around the clock, significantly reducing production time and increasing output.

Moreover, the cost savings associated with automation are substantial. While the initial investment in automation technology can be significant, the long-term benefits far outweigh the costs. By reducing labor requirements and minimizing defects, manufacturers can lower their operational expenses and pass on these savings to consumers in the form of more affordable appliances.

Another crucial aspect of automation is the improvement in product quality. With the precision and consistency that automation offers, the risk of defects is greatly reduced. This not only ensures that customers receive a high-quality product but also enhances the reputation of the brand. Consistency in manufacturing also allows for the production of complex and sophisticated appliances that were previously difficult to achieve manually.

The integration of automation into kitchen appliance manufacturing has also led to increased flexibility. Manufacturers can easily adapt their production lines to accommodate new models and features. This agility is particularly important in an industry where product lifecycles are short, and innovation is key to staying competitive.

Furthermore, automation has brought about a new level of safety in the workplace. Manual assembly lines were often hazardous, with workers exposed to repetitive tasks and potential injuries. By automating these tasks, the risk of workplace accidents is significantly reduced, creating a safer environment for employees.

In the realm of sustainability, automation has played a crucial role as well. By optimizing energy usage and reducing waste, automated production lines contribute to a greener manufacturing process. This is particularly important as consumers become more environmentally conscious and demand sustainable practices from the brands they support.

The rise of automation in kitchen appliances has also spurred the development of new skills within the workforce. While some jobs have been displaced by automation, new roles have emerged that require specialized knowledge in operating and maintaining these advanced systems. This shift in the labor market is preparing the industry for the future, where a skilled workforce is essential for continued success.

As the kitchen appliance industry continues to evolve, it’s clear that automation will remain a driving force. The benefits of increased efficiency, cost savings, improved product quality, flexibility, safety, sustainability, and the development of new skills make automation an indispensable part of the industry’s future. By embracing automation, manufacturers are not only meeting the needs of today’s consumers but also preparing for the challenges and opportunities of tomorrow.

In the ever-evolving landscape of kitchen appliances, the introduction of the automated air fryer assembly line marks a significant shift. This line isn’t just a series of interconnected machines; it’s a symphony of precision and efficiency that’s transforming how these popular kitchen gadgets are made.

The heart of this assembly line lies in its robotic arms, which are the backbone of the production process. These arms are designed with remarkable precision, capable of handling intricate tasks with a finesse that’s unmatched by human hands. They move with an almost balletic grace, deftly placing components into their designated slots, ensuring that every air fryer that rolls off the line is as uniform as the last.

At the beginning of the line, raw materials are meticulously sorted and prepared. Sheets of metal are cut to precise dimensions, and electronic components are sorted and counted. This initial stage is critical, as it sets the foundation for the rest of the process. The automated systems here are so sophisticated that they can detect even the slightest inconsistencies in the materials, preventing any potential defects from advancing.

Once the materials are ready, the assembly process begins. The robotic arms pick up the metal sheets and fold them into the required shapes, creating the body of the air fryer. The process is rapid and seamless, with each step being timed to perfection. The precision of these machines means that every part is aligned correctly, reducing the need for manual adjustments.

Next comes the insertion of the heating elements. This is a delicate task, as the elements must be placed precisely within the fryer’s walls to ensure even heating. The automated assembly line handles this with ease, using robotic grippers that are designed to hold the elements steady while they’re inserted. Sensors within the assembly area ensure that the elements are positioned correctly, every time.

The air fryer’s electronics are then connected, a process that requires both precision and speed. The robotic arms work with a remarkable degree of coordination, threading wires through tiny conduits and securing them with clips. The automated systems monitor the connection points for continuity, guaranteeing that there are no breaks in the circuitry.

As the electronics are being installed, the outer casing is being prepared. Another set of robotic arms apply heat to the metal, bending it to the correct shape. This process is highly controlled, with the temperature and duration of the heat being meticulously adjusted to avoid warping or cracking.

Once the casing is formed, it’s moved to the painting station. Here, automated systems spray the casing with a fine mist of paint, ensuring a consistent and even coat. The paint is dried quickly, and any excess is removed, leaving a smooth, glossy finish. The automated line can handle a wide range of colors and finishes, making it easy to customize the appearance of the air fryers.

After the painting, the electronics and heating elements are fully integrated into the casing. The robotic arms carefully secure the casing in place, and the air fryer is now ready for quality checks. Sensors and cameras are used to inspect the unit for any signs of defects, such as misaligned components or uneven paint.

The final step is packaging. The automated line uses conveyors to move the air fryers to a packaging area, where they are placed into boxes. The boxes are sealed, labeled, and then moved to a storage area. This entire process is monitored by a central control system that ensures everything runs smoothly and efficiently.

The impact of the automated air fryer assembly line is profound. It not only increases production speed and reduces costs but also ensures a high level of consistency and quality. The line can operate 24⁄7, with minimal downtime, leading to a significant increase in output. It also creates a safer working environment for human employees, who can focus on tasks that require creativity and problem-solving, rather than repetitive assembly work.

Moreover, the scalability of the automated assembly line is a significant advantage. As the demand for air fryers grows, the line can be easily adjusted to handle the increased volume. This flexibility is crucial in today’s market, where consumer tastes and preferences can shift rapidly.

In conclusion, the automated air fryer assembly line is more than just a method of production; it’s a testament to the power of innovation in the kitchen appliance industry. It’s a game-changer that promises to bring about further advancements in efficiency, quality, and customization, ultimately enhancing the consumer experience in the kitchen.

In the realm of kitchen appliance manufacturing, efficiency and speed are the lifeblood of success. Automation has revolutionized the industry, particularly in the assembly of air fryers, where time and precision are paramount. Let’s delve into how this technological leap has transformed the process.

The integration of robotics and advanced machinery has significantly reduced the time it takes to assemble an air fryer. Where once human hands might have taken minutes to attach components, robots can perform these tasks in fractions of a second. This dramatic decrease in assembly time means that production lines can run continuously, with each unit flowing smoothly from one station to the next.

Speed isn’t just about the time it takes to put together an air fryer; it’s also about the consistency and reliability of the process. Automation ensures that every air fryer that rolls off the line meets the same high standards of quality. The repetitive nature of assembly line work can lead to human error, but robots operate with a level of precision that is unmatched by humans.

The efficiency of the automated assembly line is not just limited to the speed of production. It also extends to the reduction of waste. By carefully managing the flow of materials and minimizing the need for manual intervention, manufacturers can cut down on the amount of scrap and unused parts. This not only reduces costs but also has a positive environmental impact.

In the air fryer assembly line, efficiency is achieved through a series of interconnected stations. Each station is designed to handle a specific task, whether it’s placing the heating element, sealing the housing, or applying the correct amount of lubricant. The seamless transition from one station to the next means that there is no downtime for workers to move between tasks, further increasing the pace of production.

The heart of automation in the air fryer assembly line lies in the integration of software and hardware. Sophisticated software systems manage the entire production process, from the initial order to the final quality check. This software ensures that the correct parts are delivered to each station at the right time, minimizing bottlenecks and keeping the line moving.

The hardware aspect is equally crucial. Robots and conveyors work in harmony to move the air fryer through the assembly process. Sensors detect when a component is in place, triggering the next step without human oversight. This level of automation means that the assembly line can operate 24⁄7, with minimal human intervention required.

Moreover, the efficiency of the automated assembly line is not just a short-term gain; it’s a strategic advantage. As consumer demand for air fryers continues to grow, manufacturers that can produce these appliances at a high volume with high quality will be better positioned to capture market share. The scalability of automation allows companies to quickly adapt to changing market conditions, whether it’s an increase in demand or the need to introduce new features.

The impact of efficiency on the bottom line is clear. With faster production times and reduced waste, companies can lower their costs and offer competitive pricing to consumers. This, in turn, can lead to increased sales and a stronger market presence.

In conclusion, the automated air fryer assembly line is a marvel of modern manufacturing. Its ability to combine speed, precision, and waste reduction has set a new standard for efficiency in the kitchen appliance industry. As technology continues to evolve, we can expect to see even more innovative solutions that will further enhance the efficiency and speed of production, ensuring that the future of kitchen appliances is not just automated but also optimized for success.

The shift towards automation in the kitchen appliance industry has brought about a remarkable transformation, especially in the assembly of air fryers. This transition isn’t just about machines taking over human tasks; it’s about the precision, consistency, and efficiency that automated processes bring to the fore. Here’s a delve into how quality control and precision are integral to producing top-notch products.

Automated assembly lines for air fryers utilize cutting-edge technologies to monitor every aspect of the manufacturing process. These systems are equipped with sensors and cameras that track the movement of parts and ensure that each component is correctly placed and assembled. This meticulous attention to detail guarantees that every air fryer that rolls off the line meets the highest standards.

In the past, manual assembly might have been prone to errors due to human fatigue, inconsistencies in hand-eye coordination, or even simple mistakes. However, with automation, these human errors are a thing of the past. The automated line moves components with a level of accuracy that’s unmatched by human hands, reducing defects to an absolute minimum.

Quality control is no longer just about checking for flaws at the end of the production process. With automation, it’s integrated into every step. As parts are added to the air fryer, each connection and seal is scrutinized for perfection. High-definition cameras and precision sensors are constantly feeding data back to the control system, ensuring that each unit is assembled with the utmost care.

The precision of the automated assembly line extends beyond just the components themselves. The tolerances for parts fitting together are extremely tight, which is crucial for the performance of the air fryer. A slight misalignment in the fryer’s basket or heating element can lead to uneven cooking or even safety hazards. Automation ensures that these components are precisely positioned, thereby avoiding these risks.

Another aspect of quality that the automated assembly line prioritizes is durability. Air fryers are subjected to high temperatures and rigorous use. The automated processes ensure that the materials used are of the highest quality and that they are securely fastened, preventing any possibility of wear and tear that could compromise the appliance’s lifespan.

Furthermore, the automated system includes rigorous testing phases. Before an air fryer is deemed complete, it is put through a series of tests that simulate real-world use. These tests include checking for electrical integrity, thermal performance, and safety features. If a unit fails any of these tests, it is immediately flagged and removed from the line, preventing any defective products from reaching the consumer.

The use of AI and machine learning algorithms in the quality control aspect of the assembly line has been particularly revolutionary. These systems can predict potential failures by analyzing patterns in data collected from previous units. This predictive maintenance not only ensures the quality of the current product but also helps in planning maintenance for the machines themselves, reducing downtime and further enhancing efficiency.

Moreover, the precision of the automated line has led to significant advancements in product design. Designers can push the boundaries of innovation, knowing that the automated system can handle intricate parts and complex geometries. This has resulted in air fryers with sleeker designs, more features, and improved usability, all without compromising on quality.

In the realm of quality control and precision, the automated air fryer assembly line is not just about the end product; it’s about the entire experience. From raw materials to the final packaging, every aspect of the production process is controlled and monitored, ensuring that customers receive a product that not only performs flawlessly but also stands out as a testament to modern manufacturing capabilities.

In summary, the combination of precision technology and robust quality control measures in the automated air fryer assembly line has revolutionized the industry. It’s not just about the speed of production—it’s about the assurance of a product that is reliable, efficient, and meets the evolving expectations of consumers.

In the ever-evolving landscape of kitchen appliance manufacturing, the introduction of automated systems has not only transformed the way products are made but has also opened up new avenues for cost savings and scalability. Let’s delve into how these two factors intertwine with the rise of automation in the industry.

The cost-saving aspect of automation is multifaceted. Firstly, by automating repetitive tasks, manufacturers can significantly reduce labor costs. Human workers are prone to fatigue and error, whereas machines can operate tirelessly and with precision. This reduction in labor costs allows companies to allocate resources more strategically, focusing on innovation and customer service rather than on maintaining a large workforce.

Secondly, the efficiency of automated systems minimizes waste. In traditional manufacturing processes, there is often a considerable amount of waste due to errors, defects, or inefficiencies. Automation streamlines operations, reducing the likelihood of waste and ensuring that materials are used to their fullest potential. This not only cuts down on material costs but also has a positive environmental impact.

Scalability is another critical advantage of automation. As consumer demand fluctuates, manufacturers need to be able to adjust their production levels accordingly. With manual labor, scaling up or down can be a complex and time-consuming process. Automation allows for quick and seamless adjustments to production volume. Whether it’s a surge in orders or a temporary drop in demand, an automated system can adapt with relative ease.

In terms of cost savings, the initial investment in automated equipment can be substantial. However, the long-term financial benefits often outweigh the initial outlay. For instance, the longevity of automated systems means they can be used for years, reducing the need for frequent replacements. Additionally, the consistent output of these systems ensures that products meet the same high standards every time, reducing the risk of recalls or returns that can be costly for businesses.

The scalability of automation also extends to the introduction of new products. When a new kitchen appliance is developed, the automated assembly line can be reprogrammed to accommodate the new design. This agility means that companies can bring new products to market faster, keeping them competitive in a fast-paced industry.

Furthermore, the cost savings from automation can be reinvested into research and development. Companies can use the savings to fund innovation, which can lead to even more efficient manufacturing processes and products that are more appealing to consumers. This cycle of continuous improvement keeps the company at the forefront of technological advancements in kitchen appliances.

Another area where cost savings are realized is in energy consumption. Automated systems are designed to be energy-efficient, which can lead to significant savings on utility bills. As the cost of energy continues to rise, these savings can have a substantial impact on a company’s bottom line.

In terms of scalability, automation can also help companies manage their inventory more effectively. With an automated system, production can be scheduled based on actual sales data, ensuring that there is no excess inventory sitting on shelves. This lean inventory approach minimizes storage costs and reduces the risk of product obsolescence.

Lastly, the scalability of automation is not just about production volume; it’s also about geographical expansion. As companies look to expand into new markets, they can replicate their automated assembly lines with relative ease. This allows for consistent product quality across different regions, which is crucial for building a strong brand reputation.

In conclusion, the combination of cost savings and scalability is a cornerstone of the automation revolution in kitchen appliances. By reducing labor and material costs, optimizing energy use, and allowing for rapid adjustments to production, automation is not just changing how appliances are made—it’s changing the entire business model for manufacturers in this sector.

In the realm of kitchen appliance manufacturing, the shift towards automation has not only streamlined processes but also prioritized the safety and well-being of workers. This focus on ergonomics has become a cornerstone of modern assembly lines, particularly in the production of air fryers.

The integration of ergonomic principles into the automated air fryer assembly line has led to a noticeable transformation. Workers are no longer burdened with repetitive tasks that can lead to physical strain and injury. Instead, they are engaged in roles that require less physical exertion and more cognitive skills.

One of the key benefits of ergonomic design in the assembly line is the reduction of manual labor. Tasks such as inserting components, securing parts, and inspecting products are now handled by robots and automated machinery. This not only minimizes the risk of repetitive strain injuries (RSIs) but also allows workers to focus on more complex and fulfilling tasks.

The layout of the assembly line is meticulously planned to ensure that workers can perform their duties without unnecessary physical stress. Workstations are designed with adjustable height, allowing employees to work in a comfortable posture. The placement of tools and materials is optimized to minimize the distance workers need to travel, reducing the risk of fatigue and accidents.

Safety features are integrated into every aspect of the automated air fryer assembly line. Sensors and emergency stop buttons are strategically placed to prevent accidents. For example, if a worker needs to access a part that is out of reach, they can use a lift or a platform to reach it safely, rather than climbing or stretching awkwardly.

Moreover, the design of the line takes into account the natural movement patterns of the human body. Workers are encouraged to move in a fluid and natural way, with tasks that require bending, reaching, or lifting being designed to minimize strain. This approach not only enhances safety but also improves productivity, as workers are less likely to experience discomfort or fatigue.

In the past, the assembly of air fryers might have involved workers manually handling hot components or sharp tools, which posed significant safety risks. Today, these tasks are automated, eliminating the need for workers to be exposed to such hazards. The use of robotic arms and precision machinery ensures that components are handled with the utmost care, reducing the risk of accidents and injuries.

Ergonomic training is also a crucial component of the workforce’s safety and well-being. Workers are educated on the proper use of tools, the importance of maintaining a good posture, and how to report any potential hazards. This proactive approach to safety has led to a more informed and cautious workforce.

The impact of ergonomic design on the automated air fryer assembly line extends beyond just safety. It also contributes to the overall satisfaction and morale of the workers. When employees feel that their well-being is a priority, they are more likely to be engaged and productive.

In conclusion, the emphasis on safety and ergonomics in the automated air fryer assembly line is a testament to the industry’s commitment to its workforce. By reducing physical strain, minimizing hazards, and promoting a healthy work environment, the assembly line not only ensures the production of top-notch products but also upholds the dignity and comfort of the workers who bring these products to life.

The automated assembly line for air fryers isn’t just a step forward in manufacturing; it’s a leap into a new era of efficiency and precision. These lines are meticulously designed to streamline the production process, ensuring that each air fryer that rolls off the line is not just a product but a testament to cutting-edge technology.

In the heart of these assembly lines, robotics play a pivotal role. Robots, equipped with precision tools and sensors, handle tasks that were once the domain of human workers. The result is a level of consistency and speed that manual labor simply cannot match. The assembly of components like heating elements, fans, and control panels is now done with pinpoint accuracy, reducing the likelihood of defects and ensuring that every air fryer meets the highest quality standards.

The integration of advanced sensors has been a game-changer. These sensors monitor the assembly process, detecting any anomalies or deviations from the intended specifications. In the past, such errors might have gone unnoticed until the product was in the hands of the consumer. Now, they are caught and corrected immediately, which not only prevents defective products from reaching the market but also saves on the costs associated with returns and repairs.

The speed at which these automated lines operate is remarkable. With robotic arms and conveyors working in harmony, the assembly of an air fryer can be completed in mere minutes. This rapid pace means that manufacturers can produce a higher volume of air fryers in a shorter amount of time, meeting the increasing demand without sacrificing quality.

Moreover, the scalability of these automated assembly lines is unparalleled. As consumer preferences shift and new models are developed, the lines can be easily reprogrammed or retooled to accommodate these changes. This flexibility ensures that manufacturers can stay ahead of the curve, introducing new features and designs without the need for a complete overhaul of their production facilities.

In terms of cost savings, the benefits are clear. While the initial investment in an automated assembly line can be substantial, the long-term savings are significant. By reducing the need for manual labor, manufacturers can cut down on labor costs and reduce the likelihood of workplace injuries. Additionally, the precision of the robots means fewer products are scrapped due to defects, saving on material costs.

But it’s not just about the bottom line; it’s also about the workers themselves. Safety and ergonomics are at the forefront of these automated systems. The repetitive tasks that once caused strain and fatigue for workers are now handled by robots, which eliminates the risk of repetitive strain injuries. Workers are freed up to perform more complex tasks that require human judgment and creativity, tasks that robots cannot yet replicate.

The automated assembly line also creates a safer work environment. Robots handle the hot and hazardous parts of the assembly process, reducing the risk of burns and other workplace accidents. Workers can now focus on tasks that require dexterity and problem-solving skills, which is not only safer but also more fulfilling.

As we look to the future, the innovations in air fryer technology are as exciting as they are varied. From smart features that allow for remote monitoring and control to eco-friendly materials that reduce energy consumption, the possibilities are vast. The automated assembly lines are ready to adapt to these new innovations, ensuring that each air fryer is not just a kitchen appliance but a beacon of innovation and efficiency.

The integration of AI and machine learning into these assembly lines is another area of growth. These technologies can predict maintenance needs, optimize production schedules, and even suggest improvements to the assembly process. The result is a system that not only produces high-quality air fryers but also continuously learns and improves, ensuring that the future of kitchen appliances is bright and filled with possibilities.

In the ever-evolving landscape of the kitchen appliance industry, the introduction of the automated air fryer assembly line has sparked a transformative wave. This shift towards automation is not just a trend; it’s a strategic move that’s reshaping the way air fryers are produced, distributed, and consumed. Let’s delve into how this transition is impacting the industry at large.

The adoption of automated systems in air fryer manufacturing has led to a significant reduction in labor costs. With machines handling the majority of the assembly process, the need for a large workforce diminishes. This change has allowed companies to allocate resources more effectively, focusing on innovation and customer service rather than on payroll expenses. The result is a more streamlined operation that’s not only cost-efficient but also scalable.

As the demand for air fryers continues to soar, the scalability of automated assembly lines is a game-changer. These lines can be easily expanded or reconfigured to accommodate increased production volumes without the traditional constraints of hiring additional workers. This flexibility is crucial for staying competitive in a market where consumer preferences can shift rapidly.

Safety has always been a top priority in manufacturing, and automation has brought a new level of security to the assembly line. The elimination of manual tasks that involve handling hot components or moving heavy objects significantly reduces the risk of workplace accidents. Workers are no longer exposed to the hazards associated with repetitive strain injuries or the dangers of working with high-temperature machinery.

The integration of advanced sensors and robotic systems has also had a profound impact on the quality of air fryers. These technologies ensure that each unit is assembled with precision, minimizing the likelihood of defects. The result is a higher standard of product quality, which not only satisfies customers but also enhances the brand reputation.

The shift to automated assembly lines has also encouraged companies to invest in ongoing training for their workforce. While automation has reduced the number of manual tasks, it has also created a need for skilled operators who can manage and maintain the sophisticated machinery. This investment in training has led to a more knowledgeable and adaptable workforce, capable of handling the complexities of modern manufacturing processes.

Innovation in the air fryer market is flourishing, with manufacturers pushing the boundaries of what these appliances can do. The automated assembly line has played a pivotal role in this innovation, allowing for the integration of new features and technologies that were once considered too complex or costly to implement. Features like smart connectivity, advanced cooking modes, and health-conscious design are now more accessible to a wider audience.

The impact of the automated air fryer assembly line extends beyond the manufacturing floor. Retailers are seeing increased efficiency in restocking shelves, as automated systems can produce a steady stream of air fryers without the delays associated with traditional manufacturing. This has led to more consistent availability for consumers, reducing the time they spend searching for the latest models.

From an environmental standpoint, the automation of the assembly line has also made a positive impact. By reducing the energy consumption and waste associated with manual processes, manufacturers are able to produce air fryers in a more sustainable manner. This is an increasingly important factor for consumers who are becoming more environmentally conscious in their purchasing decisions.

The rise of the automated air fryer assembly line has not only improved the efficiency and quality of production but has also paved the way for a new era of innovation. As the industry continues to evolve, we can expect to see even more sophisticated appliances that not only make cooking easier and healthier but also contribute to a more sustainable and efficient world. The air fryer market is just the beginning of a broader transformation that will likely reshape the entire kitchen appliance industry.

In today’s fast-paced world, the kitchen appliance industry is continually evolving, with a particular focus on the air fryer market. This surge in innovation and automation has brought about significant changes, reshaping how these products are designed, manufactured, and received by consumers. As we reflect on the journey, it’s clear that embracing the new era of kitchen appliances is not just a trend but a necessity for the industry’s growth and sustainability.

Automation has undeniably become the backbone of efficiency and precision in manufacturing. It’s not just about speed; it’s about the quality and consistency of the end product. In the realm of air fryers, this transformation is evident in every aspect of the assembly process. From the initial stages of part handling to the final quality checks, automation has introduced a new level of reliability.

The precision of automated systems is unparalleled. Sensors and robotic arms work in tandem to ensure that each component is placed with extreme accuracy. This level of detail is crucial for the functionality of an air fryer, where even a slight misalignment can affect performance. The result is a product that not only looks impeccable but also performs as expected, time and time again.

In terms of cost savings, the benefits are twofold. Initially, the setup costs for an automated assembly line are substantial, but over time, these investments pay off through reduced labor costs and increased productivity. With fewer workers required to perform repetitive tasks, companies can allocate their human resources to more creative and strategic endeavors.

Moreover, the scalability of automated lines is a game-changer. As consumer demand fluctuates, manufacturers can easily adjust production levels without the need for a complete overhaul of their facilities. This flexibility allows companies to remain agile in a market that is constantly evolving.

Safety has always been a paramount concern in manufacturing. Automation has significantly improved safety standards on the assembly line. By removing human workers from hazardous tasks, the risk of accidents is minimized. Ergonomic designs for machinery and equipment further protect employees, reducing the likelihood of repetitive strain injuries.

The impact of automation extends beyond the manufacturing floor. It influences how products are marketed and sold. With streamlined production, companies can offer more competitive pricing, making their products more accessible to a wider audience. This accessibility, in turn, fosters brand loyalty and market share growth.

The air fryer market, in particular, has seen a surge in consumer interest, driven by health-conscious trends and the convenience of modern lifestyles. As innovations continue to pour in, the future of air fryers looks promising. We’re seeing a blend of technology and design that promises to revolutionize the way we cook and eat.

One such innovation is the integration of smart technology into air fryers. These devices can now be connected to smartphones and tablets, allowing users to monitor and control their cooking remotely. The potential for personalized recipes and cooking programs is vast, offering consumers a level of customization that was once unimaginable.

In terms of environmental sustainability, advancements in materials and manufacturing processes are making air fryers more eco-friendly. From the use of recycled materials to energy-efficient designs, manufacturers are increasingly mindful of the environmental impact of their products.

The market analysis for the air fryer industry reveals a dynamic and rapidly growing sector. As more consumers adopt healthier lifestyles and seek out kitchen appliances that align with these values, the demand for air fryers is expected to soar. This growth is not limited to a single market; it’s a global phenomenon.

As we conclude our exploration of the new era of kitchen appliances, it’s clear that the industry is on the cusp of a transformative period. Automation, efficiency, quality, cost savings, and safety are all integral to this new landscape. The air fryer assembly line is just one example of how the industry is adapting to meet the needs of the modern consumer.

The road ahead is paved with opportunities for innovation and improvement. As manufacturers continue to push the boundaries of what’s possible, we can expect to see even more impressive advancements in kitchen appliance technology. It’s an exciting time to be part of the kitchen appliance industry, as it embraces a future that promises to make cooking and living healthier, more convenient, and more sustainable.