The Arctic Grade Waffle Maker, a modern kitchen equipment, is designed particularly for cooking in intense bloodless environments. perfect for towns like Nome, Alaska, it offers a new culinary option for households enduring harsh winters. Its progressive layout consists of unique substances and insulation, ensuring durability and efficient overall performance in sub-0 temperatures. This waffle maker now not best meets the primary cooking desires however also enhances the eating revel in, setting a new benchmark for kitchen home equipment in cold climates.

The OEM kitchen home equipment market is witnessing a surge in call for for diverse, customized, and power-green merchandise. manufacturers are that specialize in innovation, integrating smart technology to beautify consumer revel in and performance. Customization, wise improvements, and

designs are key developments, with agencies like Midea and Haier main the fee globally. As technology advances, OEM kitchen equipment manufacturers ought to hold to innovate and optimize their supply chains, advertising techniques, and R&D efforts to maintain a competitive facet and cater to evolving consumer desires.

the commercial waffle maker factory zone is prospering because of the speedy growth within the catering industry and patron call for for healthful, rapid options. As manufacturers like to ensure their merchandise are a sure choice, they consciousness on innovative designs with clever capabilities like computerized temperature control, multifunctionality, and

materials. those advancements cater to diverse marketplace desires, from fitness-conscious purchasers to busy institutions like cafes and restaurants. through emphasizing excellent, after-income provider, and brand building, manufacturers like to put their Waffle Irons because the move-to desire for both groups and clients.

Ningbo’s kitchen appliance supplier stands out as a leading force within the enterprise, boasting a month-to-month production capability of 10,000 gadgets. This town’s producers are famend for their progressive designs and green production strategies, catering to numerous consumer needs. With a focal point on technological advancements and sustainable practices, Ningbo’s kitchen appliance providers are using marketplace increase and setting a benchmark for first-class and efficiency within the enterprise. Their dedication to innovation and worldwide enlargement has solidified Ningbo’s reputation as a hub for pinnacle-tier small appliances.

within the rapidly evolving chinese language kitchen appliance market, cutting-edge layout is vital for increase. East China’s OEM factories, with their mature commercial chains and advanced technology, are leading the fee. these manufacturers, known for his or her scale and supply chain performance, are innovating to satisfy rising demands for clever, energy-efficient, and multi-practical home equipment. regardless of demanding situations like cloth rate fluctuations and labor prices, they may be making an investment in R&D to enhance product value and increase into international markets. The enterprise’s awareness on purchaser revel in, in conjunction with safety and health-conscious functions, guarantees that chinese manufacturers are certain to dominate the cooking appliance region.

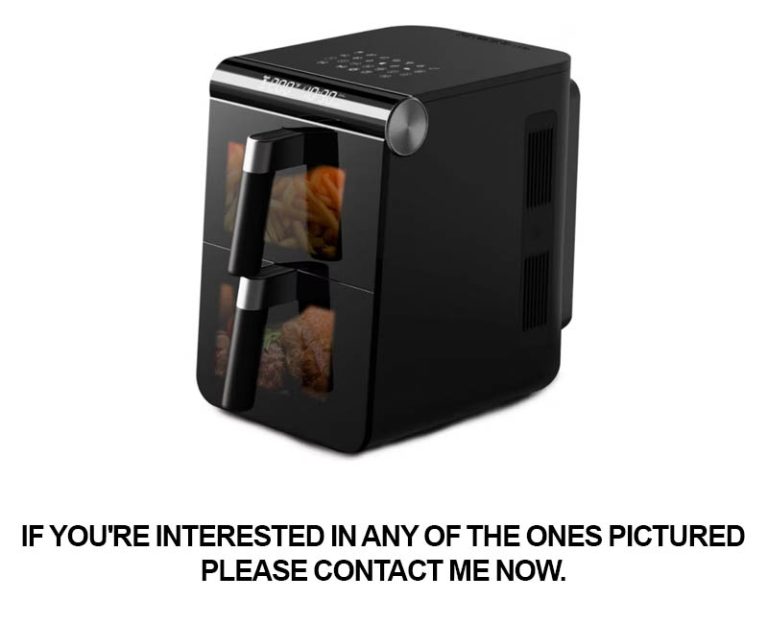

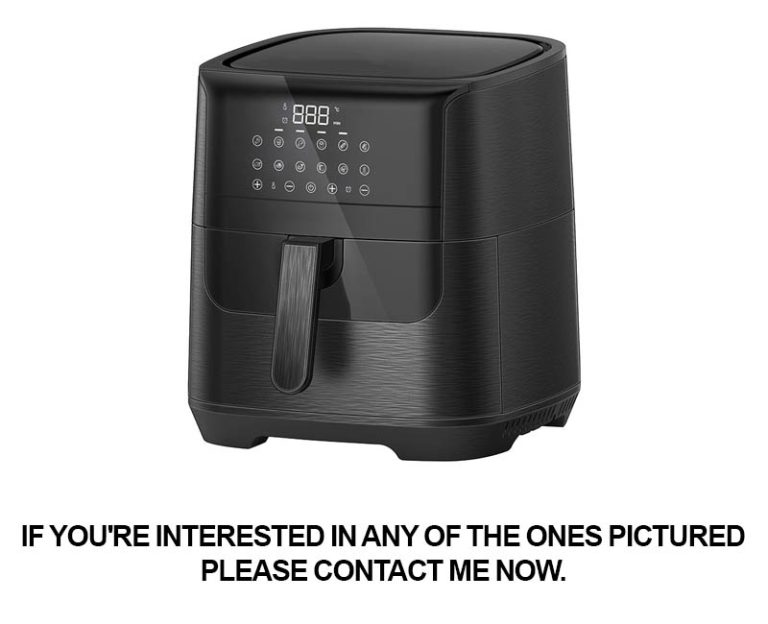

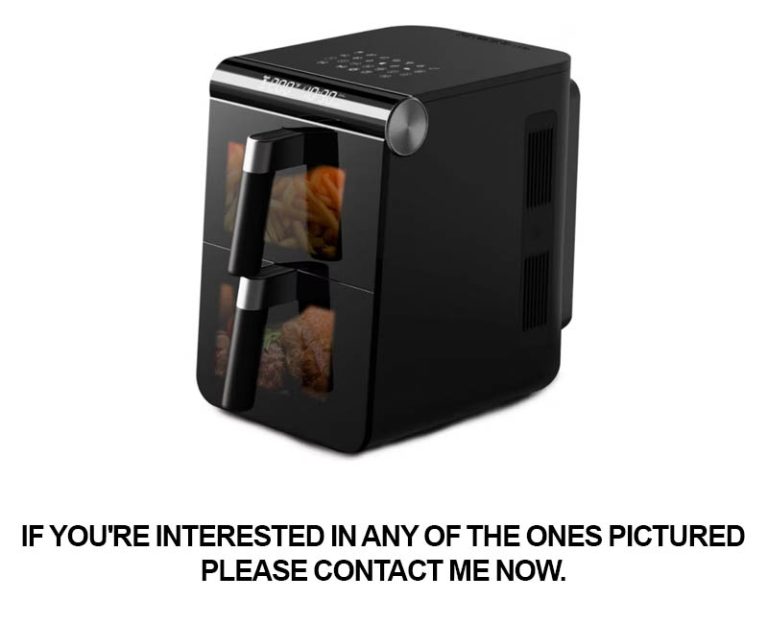

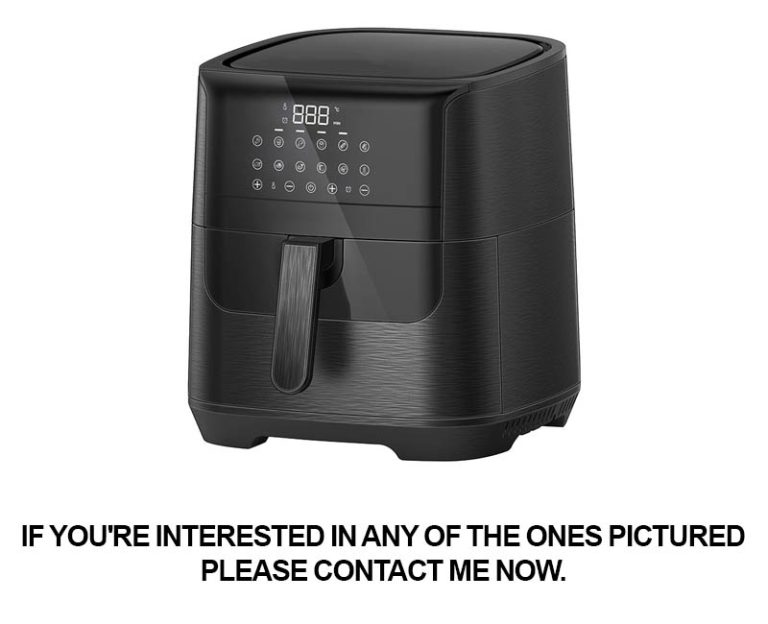

Amidst globalization and fierce opposition inside the kitchen appliance enterprise, air fryers have received recognition because of their wholesome and convenient functions. For air fryer OEM producers, CE certification is a crucial component for marketplace access and competitiveness. The market is marked by way of product diversification, technological improvements, and severe emblem rivalry. CE certification ensures compliance with european protection and environmental requirements, enhancing emblem image and consumer trust. To thrive, OEMs ought to innovate constantly, focusing on smart capabilities,

substances, multi-practical integration, and custom designed services to fulfill evolving client demands.

The EAC compliant sandwich maker manufacturing unit has seen a surge in demand as consumers more and more opt for wholesome, handy living. those revolutionary gadgets, popular in towns, cater to a numerous variety of wishes, from health-aware purchasers searching for whole grain options to households playing multifunctional home equipment that offer greater than simply bread-making. With a focal point on protection, fitness, and environmental sustainability, those factories ensure that their sandwich makers meet stringent eu standards, appealing to a global marketplace looking for sure, wholesome, and green kitchen solutions.

Low MOQ air fryer producers are capitalizing on the surge in call for for wholesome cooking with their adaptable procurement thresholds. those manufacturers provide a golden opportunity within the market, allowing small corporations and startups to go into effortlessly. The low MOQ policy enables producers to respond quickly to marketplace changes, innovate product designs, and cater to niche markets. notwithstanding challenges like better unit charges, these businesses can thrive by means of that specialize in R&D, optimizing supply chains, and constructing strong brands. Technological advancements and the emphasis on smart design further decorate their market capability, riding growth thru on-line channels and international growth.

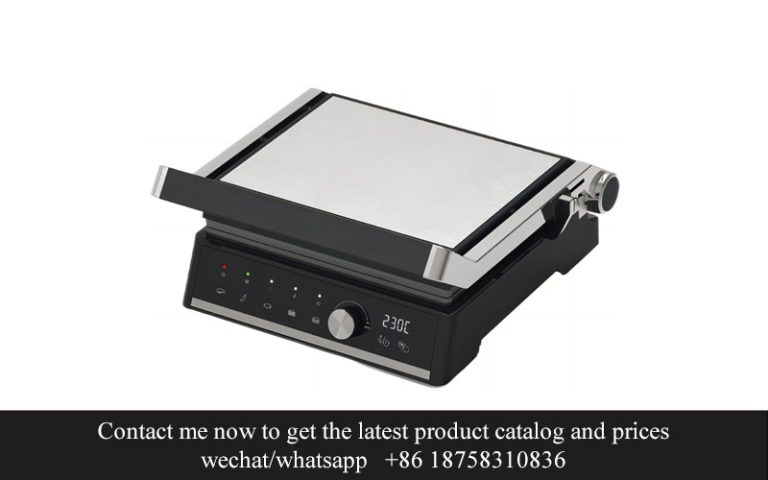

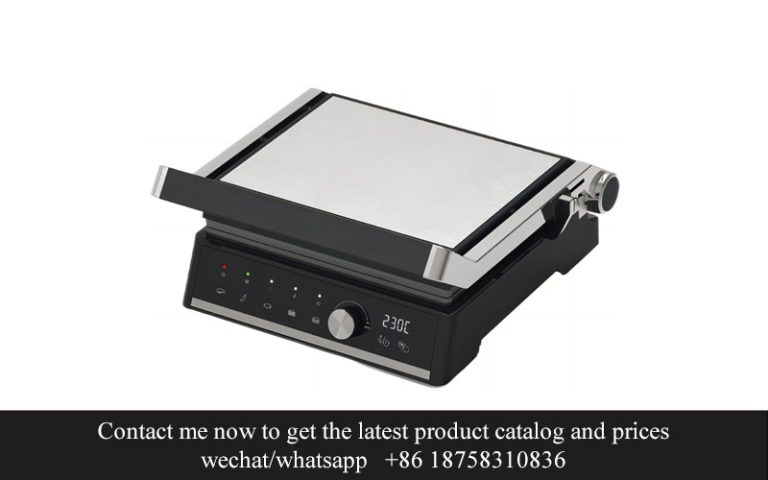

The customizable touch grill OEM marketplace is experiencing good sized increase, driven by patron call for for personalised kitchen system and the need for efficiency in catering industries. To gain a 30% price reduction on this sector, innovative strategies together with material innovation, design optimization, automation, and lean production are critical. by integrating the deliver chain, enforcing energy-saving measures, and optimizing human resources, corporations can maintain product high-quality at the same time as improving market competitiveness. A case have a look at of a specialized grill plate producer demonstrates how these strategies, which includes material enhancements and automatic manufacturing lines, caused sizable price savings with out compromising efficiency.

within the bustling metropolis appliance market, high-volume juicer production traces are in excessive call for. producers are optimizing their procedures to make certain a forty eight-hour short quoting system, making sure efficient shipping and customer pleasure. through integrating advanced automation and deliver chain management, they’re assembly the speedy reaction needs of the market, ensuring

juicers that cater to each residential and commercial customers. This recognition on pace and reliability is crucial for manufacturers to live aggressive and certain of their provider offerings.