Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the bustling world of culinary innovations, the industrial panini press has quietly become a cornerstone in the foodservice industry. Its ability to deliver consistent, appetizing paninis with minimal effort has made it a favorite among both chefs and diners alike. As we delve into the world of kitchen appliances, it’s fascinating to explore the science, aesthetics, and practicality that make the industrial panini press a game-changer. Let’s uncover why businesses are embracing this technology and what it means for the future of foodservice.

The industrial panini press has quietly but surely been making waves in the culinary scene, transforming the way we think about fast, delicious sandwiches. Once a staple in the realm of casual dining and food trucks, this versatile appliance is now becoming a must-have in professional kitchens across the globe. Let’s take a closer look at how the industrial panini press has become a game-changer in the culinary world.

Firstly, the convenience factor cannot be overstated. With its ability to cook a perfectly toasted panini in mere minutes, the industrial panini press has become a favorite among busy chefs and restaurant owners. The compact design and ease of use mean that even the most hectic kitchen can benefit from this time-saving marvel.

One of the key reasons for the rise of the industrial panini press is its versatility. Unlike traditional toasters, these presses can handle a variety of bread types, from thick ciabatta to delicate baguettes, and even gluten-free options. This adaptability has made them a favorite among chefs who want to offer a diverse menu without compromising on quality.

The technology behind the industrial panini press is also a major draw. These machines are equipped with precise temperature controls, allowing chefs to achieve the perfect level of crispiness and doneness for each sandwich. The adjustable heating elements ensure that every ingredient, from the cheese to the vegetables, is cooked to perfection.

In the world of foodservice, speed is everything, and the industrial panini press delivers on this front. With its ability to cook multiple sandwiches simultaneously, these presses can handle large orders with ease. This efficiency is particularly beneficial in high-volume settings, such as stadiums, festivals, and even busy cafes and delis.

Moreover, the industrial panini press is not just about speed and convenience; it’s also about creating a unique dining experience. The visual appeal of the freshly cooked sandwiches, with their golden-brown crusts and melted cheese, is hard to resist. This visual cue can entice customers and increase sales, as they can see the quality and freshness of the food right before their eyes.

Another factor contributing to the popularity of the industrial panini press is its ease of maintenance. These machines are designed to be user-friendly and straightforward to clean. The non-stick surfaces and removable parts make it a breeze to keep the press in top condition, ensuring that it will continue to perform well over time.

The rise of the industrial panini press has also been influenced by the growing demand for healthier food options. As more consumers look for nutritious and balanced meals, the press allows chefs to create sandwiches that are not only delicious but also packed with fresh ingredients. The ability to customize each sandwich to the customer’s preference has become a significant selling point for many restaurants.

Additionally, the industrial panini press has become a favorite among food truck operators. These mobile chefs can easily integrate the press into their compact kitchens, offering a variety of sandwiches that cater to different tastes and dietary needs. The portability and durability of these presses make them an ideal choice for those who are always on the move.

In the realm of innovation, the industrial panini press has also adapted to the needs of the modern consumer. New models are now equipped with features like adjustable pressure settings, allowing for a variety of cooking styles, from the classic press to a more open-grilled sandwich. This flexibility has opened up a world of possibilities for creative chefs looking to push the boundaries of sandwich-making.

As the culinary scene continues to evolve, the industrial panini press is poised to play an even greater role. With its combination of speed, versatility, and ability to deliver high-quality sandwiches, it’s no wonder that this appliance has become a staple in many professional kitchens. The future looks bright for the industrial panini press, as it continues to revolutionize the way we think about quick-service dining.

The kitchen appliance industry has undergone a remarkable transformation over the years, evolving from simple tools to sophisticated machines that enhance both the culinary experience and the efficiency of food preparation. As we delve into this dynamic market, several key aspects emerge, offering insights into the current state and future trajectory of the industry.

The market is segmented by product type, with ranges from basic appliances like toasters and blenders to specialized equipment such as commercial ovens and mixers. Each category has its own set of trends and consumer demands. For instance, the demand for smart kitchen appliances has surged, driven by the tech-savvy generation that seeks convenience and connectivity in their daily lives.

Consumer preferences play a pivotal role in shaping the market. Modern consumers are not just looking for appliances that perform their intended functions but also for those that offer a seamless integration with their lifestyle. This includes energy efficiency, ease of use, and aesthetic appeal. Brands that manage to align their products with these values often find themselves at the forefront of market trends.

The rise of e-commerce has significantly impacted the kitchen appliance industry. Online platforms have expanded the reach of manufacturers and distributors, allowing them to tap into a broader customer base. This shift has also led to increased competition, as more players enter the market with innovative products and competitive pricing strategies.

Innovation is a cornerstone of the kitchen appliance industry. Continuous advancements in technology have led to the development of appliances that are not only more efficient but also more versatile. For example, induction cooktops have gained popularity due to their precise temperature control and energy-saving capabilities. Similarly, the integration of IoT (Internet of Things) technology has enabled appliances to communicate with each other and with the user, providing a level of convenience and control that was once unimaginable.

The market is also influenced by regulatory changes and environmental concerns. Governments around the world are implementing stricter energy efficiency standards, pushing manufacturers to produce more sustainable appliances. This shift has led to the development of eco-friendly materials and energy-saving technologies, which are becoming increasingly important in the design and production of kitchen appliances.

Another notable trend is the customization of appliances. Consumers are looking for products that can be tailored to their specific needs, whether it’s a countertop oven with programmable settings or a refrigerator that can be remotely controlled via a smartphone app. This trend reflects a growing desire for personalization in every aspect of life, including the kitchen.

The global kitchen appliance market is diverse, with different regions showing varying levels of growth and demand. For instance, emerging markets like Asia and Latin America are experiencing rapid growth due to increasing urbanization and a rising middle class. In contrast, mature markets in Europe and North America are seeing a shift towards premium and specialty appliances as consumers seek to upgrade their kitchen setups.

The competitive landscape is characterized by a mix of large multinational corporations and smaller, niche players. The giants of the industry, such as Whirlpool, Electrolux, and BSH Hausgeräte, have significant market share and a strong presence in various segments. However, smaller companies are often able to innovate more quickly and cater to niche markets, carving out their own space in the industry.

Lastly, the kitchen appliance industry is not immune to economic fluctuations. Economic downturns can lead to decreased consumer spending on non-essential items, including kitchen appliances. Conversely, during economic upswings, there is often a surge in home renovations and kitchen upgrades, driving demand for high-quality appliances.

In summary, the kitchen appliance industry is a complex and ever-evolving market that is shaped by consumer preferences, technological advancements, regulatory changes, and economic factors. Understanding these dynamics is crucial for manufacturers, distributors, and retailers looking to succeed in this competitive landscape.

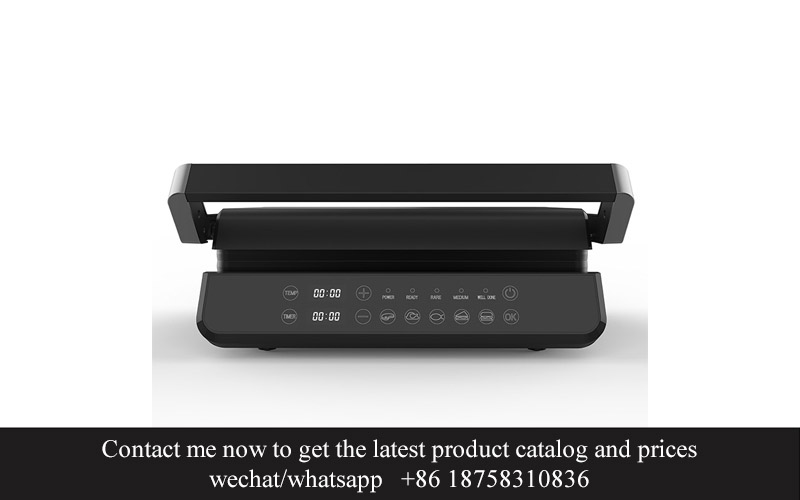

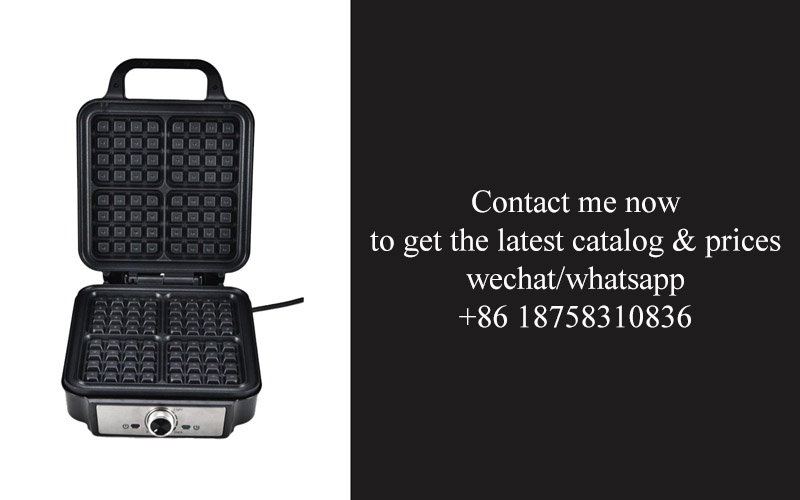

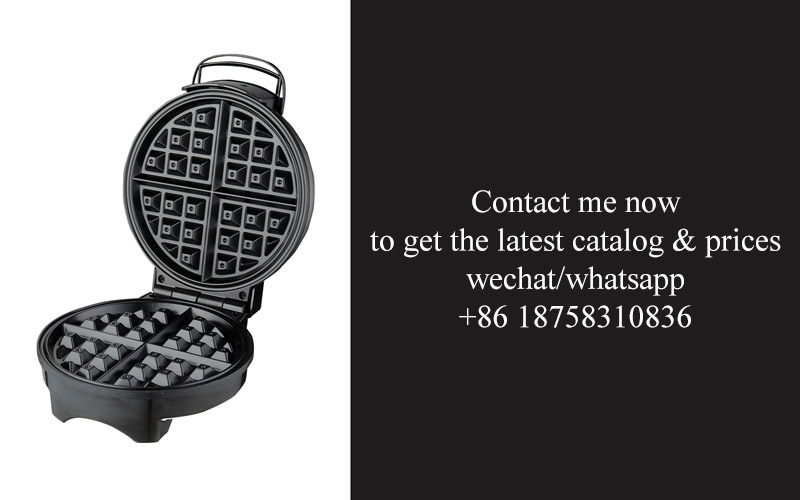

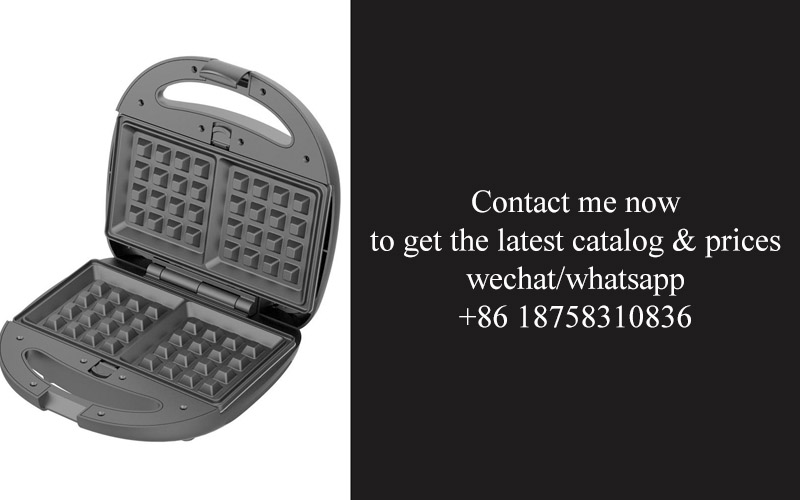

Industrial panini presses have carved a niche for themselves in the bustling kitchen appliance market, thanks to a blend of unique features and innovative design elements. Here’s a closer look at what sets these machines apart:

Commercial-Grade Build: The backbone of an industrial panini press lies in its robust construction. Made from heavy-duty materials, these presses are designed to withstand the rigors of high-volume use, ensuring they remain a reliable workhorse in busy kitchens.

Superior Heat Distribution: One of the standout features of industrial panini presses is their even heat distribution. With precision heating elements, these machines guarantee that every slice of bread, cheese, and filling is cooked to perfection, with no cold spots or burnt edges.

Variable Temperature Control: Not all paninis are created equal, and an industrial press that offers variable temperature control allows chefs to cater to different preferences. Whether it’s a melt-your-face-off jalapeño cheese sandwich or a delicate ham and cheese creation, these presses can adjust their heat settings to achieve the desired level of crispiness.

Large Cooking Surface: Designed for efficiency, industrial panini presses typically come with a spacious cooking surface. This means you can cook multiple sandwiches at once, reducing wait times and increasing throughput, especially during peak hours.

Sealing Mechanism: The sealing mechanism is a crucial aspect of any panini press. Industrial models often feature a strong, even pressure distribution system that ensures the sandwiches are pressed tightly, locking in flavors and juices for a superior taste.

Non-Stick Surfaces: To simplify cleaning and maintenance, many industrial panini presses are equipped with non-stick surfaces. This feature reduces the risk of food sticking to the plates, making it easier to clean up after a busy shift.

Fast Heat-Up Time: Time is money in the kitchen, and industrial panini presses are designed to heat up quickly. Some models can reach cooking temperature in under a minute, allowing for immediate use without any downtime.

Safety Features: Safety is paramount in commercial kitchens, and industrial panini presses come with a range of safety features. Overheat protection, automatic shut-off mechanisms, and cool-touch handles are just a few examples of how these presses are designed to keep operators safe.

Customizable Options: Some industrial panini presses offer customizable features, such as interchangeable plates or additional attachments for different cooking styles. This versatility allows kitchens to tailor the press to their specific needs and menu offerings.

Easy-to-Use Interface: Despite their advanced features, industrial panini presses are user-friendly. With intuitive interfaces and simple controls, operators can focus on cooking rather than fumbling with complex settings.

Durability and Longevity: The durability of an industrial panini press is a testament to its quality. These machines are built to last, with components that are resistant to wear and tear, ensuring years of reliable service.

Maintenance and Cleaning: Cleaning is a necessary evil in the kitchen, and industrial panini presses are designed with ease of maintenance in mind. With removable plates and components, as well as dishwasher-safe parts, cleaning these presses is a straightforward task.

Energy Efficiency: In an era where sustainability is a key concern, many industrial panini presses are designed to be energy-efficient. They use less power to maintain cooking temperatures, which can lead to significant cost savings over time.

Brand Reputation: The reputation of the brand behind the industrial panini press can also be a significant factor. Established brands often offer a warranty and customer support, giving peace of mind to businesses investing in their equipment.

Customer Reviews and Feedback: Finally, the experiences of other users can provide valuable insights into the performance and reliability of an industrial panini press. Positive reviews and feedback from fellow chefs and kitchen professionals can be a strong indicator of a product’s quality.

In summary, the uniqueness of an industrial panini press lies in its combination of durability, functionality, and innovation. From the robust build to the precise cooking capabilities, these machines are designed to elevate the culinary experience in professional kitchens.

The surge in the industrial panini press market isn’t just a fleeting trend; it’s a testament to the evolving landscape of the kitchen appliance industry. Let’s dissect the trends and data that are fueling this boom.

Demand for Versatility: One of the key factors behind the rise of industrial panini presses is the demand for versatility. These machines are no longer just for making sandwiches; they are now used for a variety of tasks, including grilling, toasting, and even baking. This flexibility has made them a must-have in commercial kitchens across the globe.

Consumer Preferences: There’s a significant shift in consumer preferences towards quick and convenient food options. As the pace of life accelerates, so does the need for efficient appliances that can churn out quality meals in a flash. Industrial panini presses cater to this need by providing a fast and easy way to serve up hot, crispy sandwiches and wraps.

Technology Integration: The integration of advanced technology in industrial panini presses has been a game-changer. Features like adjustable heat settings, non-stick surfaces, and programmable timers have transformed the way these appliances are used. They now offer precise control over the cooking process, ensuring consistent results every time.

Market Data: According to recent market research, the industrial panini press segment has seen a compounded annual growth rate (CAGR) of around 6% over the past few years. This growth is attributed to the increasing number of food service establishments, such as cafes, delis, and restaurants, that are incorporating these presses into their menus.

Eco-Friendly Initiatives: As environmental concerns grow, there’s been a rise in eco-friendly kitchen appliances. Industrial panini presses that use less energy and feature durable, recyclable materials are becoming more popular. This focus on sustainability is resonating with both businesses and consumers who are looking to reduce their carbon footprint.

Competitive Pricing: The cost of industrial panini presses has been a key driver in their widespread adoption. As competition in the market has intensified, manufacturers have been forced to innovate and offer more affordable options without compromising on quality. This has made these presses accessible to a broader range of businesses.

Culinary Innovation: The culinary industry is always on the lookout for new and exciting ways to serve food. Industrial panini presses have opened up a world of possibilities, allowing chefs and kitchen staff to experiment with different ingredients and cooking techniques. This has led to a surge in creative menu items that are both visually appealing and delicious.

Health and Wellness Trends: With a growing focus on health and wellness, there’s been a shift towards fresh, homemade meals. Industrial panini presses enable foodservice operators to offer customized sandwiches that cater to specific dietary needs and preferences. This focus on health-conscious eating is a significant trend that’s driving the demand for these presses.

Global Expansion: The industrial panini press market is not limited to any one region. It’s experiencing growth across the world, with particular spikes in developed countries where there’s a higher concentration of foodservice establishments. This global expansion is being driven by the universal appeal of the panini, which is a staple in many cultures.

Digital Marketing and Online Sales: The rise of digital marketing and e-commerce has played a pivotal role in the industrial panini press market’s growth. With more businesses turning to online platforms to reach their customers, the accessibility of these presses has increased. Manufacturers are capitalizing on this trend by offering easy-to-navigate websites and online support, making it simpler for businesses to purchase and maintain their equipment.

Brand Loyalty and Trust: Finally, the success of the industrial panini press market can be attributed to the strong brand loyalty and trust that has been established. As these presses have proven their reliability and efficiency, operators have come to rely on specific brands for their commercial kitchens. This loyalty is a testament to the quality and innovation that these brands bring to the table.

In conclusion, the industrial panini press boom is a multifaceted phenomenon that reflects broader trends in the kitchen appliance industry. From technological advancements to changing consumer preferences, the data and insights paint a picture of a market that is not only growing but also evolving in exciting ways.

The industrial panini press has emerged as a pivotal piece of equipment, reshaping the landscape of quick-service establishments from bars to cafes. Its ability to deliver fast, high-quality sandwiches has not only enhanced the customer experience but also opened up new revenue streams for businesses. Let’s delve into how this nifty gadget is redefining the quick-service industry.

With the hustle and bustle of modern life, consumers are increasingly seeking convenience and speed in their dining experiences. The industrial panini press taps into this demand by providing a quick and efficient way to prepare a variety of sandwiches. Its compact design and high-speed operation make it an ideal choice for venues where time is of the essence.

One of the standout features of the industrial panini press is its versatility. These presses are not limited to just sandwiches; they can also cook wraps, flatbreads, and even pizzas with ease. This flexibility allows cafes and bars to offer a diverse menu that caters to different tastes and preferences. The ability to customize orders on the spot adds a personal touch that can set a quick-service establishment apart from competitors.

In the competitive world of quick service, consistency is key. The industrial panini press ensures that every sandwich is cooked to perfection, with a perfectly toasted exterior and a juicy, tender interior. This consistency is achieved through precise temperature control and even pressure distribution, which is crucial for maintaining the quality of the food served.

The compact size of the industrial panini press is another advantage that appeals to businesses. It fits seamlessly into counter spaces without taking up valuable floor area. This means that cafes and bars can maximize their operational space, allowing for more seating or additional equipment. The ease of installation and maintenance also means that these presses can be up and running quickly, minimizing downtime.

The rise of health-conscious consumers has led to a growing demand for fresh, made-to-order food options. The industrial panini press aligns perfectly with this trend by offering a fresh alternative to pre-packaged snacks. Customers can witness their meal being prepared in front of them, ensuring freshness and reducing food waste.

For bars, the integration of the industrial panini press into their menu can be a strategic move. It allows bars to offer a variety of snacks that can be paired with drinks, creating a more dynamic and engaging experience for patrons. Whether it’s a gourmet grilled cheese sandwich with a side of fries or a hearty vegetable wrap, the panini press can enhance the bar’s food offerings.

Cafes, on the other hand, can leverage the industrial panini press to create a grab-and-go option that appeals to busy professionals and students. The convenience of a quick, hot sandwich or wrap can be a welcome addition to a café’s menu, attracting a broader customer base.

The technology behind the industrial panini press has also evolved to meet the needs of quick-service establishments. Features like adjustable temperature settings and non-stick surfaces make cleaning and maintenance a breeze. Additionally, some models come with safety features like automatic shut-off, ensuring the safety of both staff and customers.

In terms of cost-effectiveness, the industrial panini press offers a great return on investment. Its ability to produce multiple sandwiches at once means that it can handle high-volume orders without compromising on quality. This efficiency translates into lower labor costs and faster service times, making it a valuable asset for any quick-service establishment.

The industrial panini press has also played a role in the rise of food trucks and mobile catering services. These portable presses allow operators to bring the convenience of fresh, hot sandwiches to various events and locations, further expanding the reach of quick-service options.

In conclusion, the industrial panini press is more than just a piece of kitchen equipment; it’s a game-changer in the quick-service industry. Its versatility, consistency, and convenience have made it a staple in bars and cafes, redefining how we think about quick service. As the demand for fast, high-quality food continues to grow, the industrial panini press is poised to remain a key player in the culinary scene.

In the world of culinary appliances, the industrial panini press has emerged as a marvel of modern technology, offering a seamless blend of speed, convenience, and culinary excellence. The science behind these presses is a testament to human ingenuity, ensuring that every panini is cooked to perfection. Let’s delve into the technology that makes this possible.

The heat distribution is the cornerstone of any successful panini press. These machines are designed with precision to ensure even heat across the entire cooking surface. High-quality materials, such as stainless steel, are used to construct the plates, which not only withstand high temperatures but also maintain their shape and durability over time. Advanced heating elements are strategically placed to provide consistent heat, which is crucial for achieving that perfect sear on both sides of the sandwich.

One of the key innovations in industrial panini presses is the adjustable temperature control. This feature allows chefs and cooks to tailor the cooking temperature to the specific ingredients and desired outcome. Whether it’s a delicate turkey and cheese sandwich or a hearty beef and bacon creation, the ability to adjust the heat means every panini can be cooked to the perfect level of doneness.

The pressure mechanism is another critical aspect of the panini press. These machines apply pressure to the sandwich, which helps to seal in the flavors and create a crispy outer crust. The pressure is carefully calibrated to ensure that the bread is not overcooked or soggy. It’s a delicate balance, but the technology behind these presses ensures that every panini comes out with a satisfying crunch.

The non-stick surfaces are a game-changer for maintaining hygiene and ease of cleaning. These surfaces prevent food from sticking to the plates, which not only saves time but also reduces the need for excessive oil or butter. The non-stick coating is also designed to be durable, so it can withstand the rigors of frequent use in a busy kitchen environment.

Many industrial panini presses come with additional features that enhance the cooking experience. For instance, some models include a warming drawer, which is perfect for keeping other items hot while the press is in use. Others have a lock mechanism that prevents the lid from accidentally closing, ensuring safety in a bustling kitchen setting.

The technology doesn’t stop at the physical aspects of the press. Many modern models are equipped with digital displays that allow for precise temperature control. These displays often have memory settings, so once a user finds the perfect cooking temperature for a particular type of sandwich, they can save that setting for future use. This not only streamlines the cooking process but also ensures consistency across multiple batches.

In terms of energy efficiency, industrial panini presses are designed to be as eco-friendly as possible. They use less energy than traditional grills or skillets, which is not only cost-effective for businesses but also contributes to a greener planet. The compact design of these presses also means they take up less space in a kitchen, making them a practical choice for even the most crowded commercial kitchens.

The science of searing is also about the interaction between the heat and the food. Industrial panini presses are engineered to provide a high-heat, short-cook time that seals in the natural juices of the ingredients. This method not only ensures that the panini is juicy and flavorful but also minimizes the loss of nutrients that can occur with longer cooking times.

The technology behind these presses also includes the ability to cook a variety of foods beyond sandwiches. Many models can handle burgers, pizzas, and even pancakes, making them versatile tools in a commercial kitchen. The even heat and pressure ensure that each item is cooked to perfection, with a consistent texture and appearance.

In conclusion, the science of searing in an industrial panini press is a marvel of modern kitchen technology. From precise temperature control to pressure-sealing and non-stick surfaces, these machines are designed to make every panini an experience worth savoring. The technology behind them is a testament to the continuous innovation in the culinary appliance industry, ensuring that quick service establishments can serve up delicious, high-quality food with ease.

The sleek design of industrial panini presses has become a statement piece in many commercial kitchens, and it’s not just for show. These appliances are not just functional but also contribute significantly to the aesthetic appeal of a restaurant or café. Let’s delve into the elements that make these presses not just practical but also visually stunning.

The industrial panini presses available today come in a variety of styles, from classic black and stainless steel to more contemporary designs that include colors like red, blue, and even matte finishes. The uniformity in the color and material is a hallmark of high-quality appliances, ensuring that the press blends seamlessly into the kitchen’s overall design. This consistency is particularly important in establishments where maintaining a clean, modern look is a priority.

One of the most striking features of these presses is their sleek lines and minimalist design. The flat surfaces, clean edges, and absence of unnecessary buttons or controls give them a futuristic look that can elevate the atmosphere of any establishment. The smooth surfaces are also easy to clean, which is a significant advantage in a busy kitchen environment where hygiene is paramount.

The handle of an industrial panini press is often an afterthought, but not in these cases. The handles are designed to be ergonomic, allowing for a comfortable grip without compromising the aesthetics. Some models feature handles that match the color of the press, creating a cohesive look. Others opt for contrasting colors, which serve as a subtle yet effective design element.

The heat distribution is another aspect that impacts the visual appeal of an industrial panini press. Modern presses are equipped with advanced heat control systems that ensure even cooking across the entire surface. This not only guarantees consistent results but also contributes to the press’s professional appearance. The visibility of the heating elements is often minimized to maintain the sleek look, and some models even come with temperature displays that are integrated into the design, adding a touch of sophistication.

The build quality of these presses is also noteworthy. They are typically constructed from heavy-duty materials like stainless steel, which not only ensures durability but also contributes to their weight and stability. The robust construction gives the impression of a high-quality product, which can boost the credibility of the establishment using it.

In terms of size and placement, industrial panini presses are designed to fit into a variety of kitchen layouts. They come in different dimensions, from compact models that can be tucked into a corner to larger versions that are perfect for busy commercial kitchens. The size of the press can be tailored to the needs of the business, ensuring that it not only fits the space but also complements the surrounding equipment.

Another design aspect that cannot be overlooked is the ease of use. The simplicity of operation is often reflected in the design, with intuitive controls and clear indicators for power and temperature. These features not only make the press user-friendly but also contribute to its aesthetic appeal, as they are less likely to clutter the otherwise clean and polished look of the appliance.

The exterior of industrial panini presses often reflects the latest trends in kitchen design, which can include everything from matte finishes to metallic accents. These subtle details can make a significant impact on the overall look and feel of a commercial kitchen, as they can be coordinated with other appliances and fixtures to create a cohesive style.

Finally, the branding and logo placement on industrial panini presses can also play a role in their aesthetic appeal. High-end models often feature logos that are subtly integrated into the design, rather than being overtly displayed. This approach allows the press to maintain its sleek appearance while still conveying the brand’s image.

In conclusion, the aesthetic appeal of industrial panini presses is a combination of their sleek design, high-quality materials, and attention to detail. From the color and finish to the ergonomics and build quality, these presses are not just cooking tools; they are also an integral part of the kitchen’s visual identity. Their ability to blend functionality with style makes them a sought-after item in the commercial kitchen appliance market.

In the bustling world of commercial kitchens, where speed and quality are paramount, the industrial panini press has emerged as a game-changer. These robust machines are not just kitchen tools; they are investments that offer a blend of cost-effectiveness and efficiency. Let’s delve into why businesses are flocking to these presses.

The ability to produce high volumes of perfectly toasted sandwiches in a short amount of time is a significant draw for operators looking to streamline their service. Industrial panini presses are designed with commercial needs in mind, ensuring that they can handle the rigorous demands of a busy kitchen without compromising on performance.

These machines often come with adjustable heat settings, allowing chefs to tailor the cooking temperature to the specific requirements of different ingredients. This flexibility is crucial, as it means that operators can cater to a wide range of preferences, from the soft, melt-in-the-mouth texture of a ham and cheese panini to the crispy exterior of a gourmet turkey and avocado creation.

Durability is another key factor that makes industrial panini presses a smart investment. Constructed with heavy-duty materials, they are built to withstand the wear and tear of continuous use. This longevity means that businesses can expect to get their money’s worth over the long term, as the presses require less frequent replacement than their consumer-grade counterparts.

Efficiency extends beyond just the cooking process. Many industrial panini presses are designed with easy-to-clean surfaces and removable parts, making maintenance a breeze. This not only saves time but also reduces the likelihood of food waste due to clogged or dirty surfaces.

In terms of cost-effectiveness, the initial investment in an industrial panini press is often recouped quickly through increased sales. The ability to serve a variety of panini options at a consistent quality can attract a larger customer base, leading to higher turnover. Additionally, the speed at which these machines can produce sandwiches means that labor costs can be optimized, as fewer staff members are needed to manage the cooking process.

Another aspect that businesses consider is the space-saving design of industrial panini presses. They are compact yet powerful, fitting into limited kitchen spaces without sacrificing functionality. This is particularly beneficial in urban environments where kitchen real estate is at a premium.

Energy efficiency is also a crucial consideration. Modern industrial panini presses are engineered to minimize energy consumption while still delivering exceptional cooking results. This not only helps businesses reduce their utility bills but also aligns with the growing demand for sustainable practices in the foodservice industry.

From a marketing perspective, the use of an industrial panini press can be a powerful tool. The visual appeal of these machines, often featuring sleek designs and high-tech features, can attract the attention of customers and create a sense of modernity and professionalism. This can be particularly advantageous in competitive markets where the visual presentation of food plays a significant role in attracting diners.

The versatility of industrial panini presses is not limited to traditional sandwiches. They can be used to cook a variety of items, from wraps and flatbreads to even grilled vegetables and proteins. This adaptability allows businesses to diversify their menu without the need for additional equipment, further enhancing cost-effectiveness.

Finally, the trend towards healthier eating has also contributed to the popularity of industrial panini presses. As consumers seek out lighter, healthier options, the ability to quickly cook lean proteins and fresh vegetables in a panini press is a valuable offering. This aligns with the broader shift in the food industry towards offering more nutritious choices.

In conclusion, the decision to invest in an industrial panini press is a strategic one that offers a multitude of benefits. From the speed and consistency of the cooking process to the long-term cost savings and the ability to cater to a diverse range of customer preferences, these machines are a cornerstone of efficient and effective foodservice operations.

In the competitive world of foodservice, the demand for speed and quality is at an all-time high. Customers are looking for quick, delicious meals that don’t compromise on taste or presentation. Industrial panini presses have become a cornerstone in this quest, and for good reason. Here’s why consumers are falling in love with these versatile appliances.

Consistency is key in the food industry, and industrial panini presses deliver on this front. They ensure that every sandwich, from the first to the hundredth, is cooked to perfection. The even pressure and precise temperature control mean that there’s no risk of a soggy bun or undercooked filling, a common issue with homemade or lower-end commercial presses.

Ease of use is another major draw for customers. Industrial panini presses are designed for efficiency, with user-friendly interfaces that make operation a breeze. No more complicated settings or guesswork—these machines cater to the busy professional and the home chef alike, providing consistent results with minimal effort.

The variety of features offered by these presses is impressive. From adjustable heat settings to non-stick surfaces that simplify cleanup, these appliances are equipped to handle a wide range of recipes. Whether it’s a classic ham and cheese or a gourmet, multilayered creation, customers appreciate the versatility that these presses bring to their dining experience.

Safety is a significant concern for consumers, especially in the wake of recent health scares. Industrial panini presses are built with safety in mind, featuring heat-resistant handles, locking mechanisms to prevent accidental closure, and durable materials that can withstand high temperatures and repeated use. Customers feel confident knowing that these machines are not only efficient but also safe.

The aesthetics of industrial panini presses are also hard to ignore. Modern designs with sleek lines and durable finishes make these appliances not just functional but also a stylish addition to any kitchen. They can be a centerpiece for a cafe or a discreet yet attractive feature in a busy bar, enhancing the overall ambiance and appeal of the establishment.

In terms of cost, industrial panini presses offer great value. While they may have a higher upfront cost than some other kitchen appliances, their durability and efficiency often result in long-term savings. These presses can be used for years without significant wear and tear, reducing the need for frequent replacements.

For consumers who are conscious of their health, the appeal of industrial panini presses lies in the control they offer over ingredients and portion sizes. With these presses, it’s easy to create custom sandwiches that cater to dietary preferences and restrictions. From gluten-free to vegetarian options, the versatility of these machines allows customers to enjoy a variety of meals that suit their personal health goals.

The convenience factor cannot be overstated. In today’s fast-paced world, time is of the essence. Industrial panini presses enable customers to enjoy a freshly cooked meal in minutes, without the need to wait in long lines or navigate through busy restaurants. This convenience is particularly appreciated by those with busy schedules, such as office workers or students.

Lastly, the social aspect of the panini press cannot be underestimated. These machines are often used in group settings, where friends and family gather to cook and enjoy meals together. The interactive nature of preparing paninis can create a fun and engaging atmosphere, making these appliances not just a kitchen tool but also a social device.

In summary, the reasons consumers love industrial panini presses are myriad. From their consistent and easy-to-use design to their safety features, aesthetic appeal, and health-conscious benefits, these appliances have become a favorite among those who value speed, quality, and convenience in their food preparation.

The world of foodservice is always evolving, and one key player in this dynamic landscape is the industrial panini press. With the ability to deliver consistent and high-quality results, these presses have become a favorite among consumers and a crucial asset for businesses. Let’s delve into what makes these presses so beloved by customers.

Consistency in QualityConsumers appreciate the reliability of industrial panini presses in delivering the perfect sandwich every time. Whether it’s the classic ham and cheese or a gourmet fusion, the even distribution of heat ensures that every layer is cooked to perfection. This consistency is a major draw for customers who want a dependable quick-service meal option.

Speed and EfficiencyThe speed at which an industrial panini press can cook a sandwich is impressive. This rapid service appeals to busy customers looking to grab a quick lunch or dinner on the go. The convenience factor is not lost on customers, who often praise the press for minimizing their wait times while providing a hot, fresh meal.

Customization OptionsModern industrial panini presses offer a range of features that allow for customization. Customers love being able to stack their favorite fillings and choose between various press settings to achieve their preferred level of crispness. The versatility of these presses means that each customer can have their ideal panini experience, catering to personal taste preferences.

Portability and HygieneIn today’s health-conscious world, customers value hygiene and convenience. Industrial panini presses are often designed with ease of cleaning in mind, and their compact size makes them suitable for mobile catering and food trucks. This focus on portability and hygiene adds to the appeal, as customers feel more confident about the food they’re purchasing.

Attractiveness on the MenuThe presence of an industrial panini press on a menu is a visual cue to customers that they’ll be experiencing a quick yet satisfying meal. The sleek design and the ability to create visually appealing sandwiches contribute to the allure. Businesses that feature these presses often see an increase in interest from customers, simply because the option of a freshly made panini is an enticing prospect.

Culinary ExperimentationWith the industrial panini press, chefs can experiment with different ingredients and preparation techniques, leading to a wide variety of sandwiches that can be offered to customers. The versatility of the press means that businesses can continuously innovate and introduce new menu items, keeping the customer experience fresh and exciting.

Social Media SensationsIn the age of social media, visually stunning food items can become instant hits. The unique presentation and texture that a panini press can provide are often captured and shared online, which can significantly boost the visibility of a restaurant or café. Customers enjoy sharing these moments and are more likely to revisit or recommend a place with impressive panini offerings.

Sustainability and Environmentally Friendly OptionsAs awareness of environmental issues grows, consumers are increasingly looking for businesses that align with sustainable practices. Many industrial panini presses are now available with eco-friendly materials and energy-saving features. This eco-conscious aspect of the presses is a selling point for environmentally aware customers.

Cultural RelevancePaninis, as a sandwich form, have cultural significance across various regions. The industrial panini press allows for the reproduction of classic flavors and the adaptation of regional specialties, making them relevant and accessible to a broad demographic of customers.

In summary, the industrial panini press is more than just a cooking tool; it’s a catalyst for a customer-centric approach to foodservice. From the convenience and consistency it offers to the potential for culinary innovation, it’s no wonder that these presses have captured the hearts and tastes of consumers around the world. The love for industrial panini presses is a testament to the power of good food, great technology, and the evolving preferences of modern diners.