Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In a world where culinary trends are constantly evolving, the humble waffle has found its way into the hearts and kitchens of many. Once a cherished treat reserved for weekend brunches, the waffle has now transcended its traditional boundaries, becoming a versatile staple in both home and commercial settings. Enter the industrial waffle maker, a marvel of modern kitchen technology that’s redefining convenience and efficiency. With its robust design and powerful 220V motor, this game-changer is not just a tool for creating perfect waffles; it’s a symbol of innovation and the ever-growing demand for high-quality, versatile appliances. Let’s delve into the fascinating world of industrial waffle makers and explore how they’re reshaping the way we think about breakfast, snacks, and even desserts.

The kitchen, once a humble space for home cooks, has evolved into a bustling hub of innovation and efficiency. At the forefront of this transformation is the industrial waffle maker, a marvel that’s redefining the way we think about breakfast and beyond. These robust machines have quietly surged in popularity, becoming a game-changer for kitchens around the globe.

With their sleek designs and powerful performance, industrial waffle makers are not just for the commercial kitchen. Home chefs and aspiring bakers are embracing these appliances for their ability to produce consistent, high-quality waffles with ease. The surge in demand can be attributed to several factors that have positioned industrial waffle makers as a staple in modern kitchens.

Firstly, the convenience factor is undeniable. These machines are designed to handle high volumes, making them perfect for busy cafes, bakeries, and even large households. Their ability to churn out waffles at a rapid pace is a game-changer for those looking to serve breakfast to a crowd. The efficiency of industrial waffle makers means less time spent on the stove and more time to enjoy the delicious results.

Secondly, the versatility of these appliances is impressive. While they are most famous for creating classic Belgian waffles, many models offer adjustable settings to craft a variety of waffle shapes and sizes. From fluffy American-style waffles to intricate Belgian waffles with intricate patterns, these machines can cater to a wide range of preferences.

Another key factor in the rise of industrial waffle makers is the technology behind them. Modern models are equipped with advanced heating elements that ensure even cooking, resulting in a perfectly crisp outer layer and a tender, fluffy interior. The precise temperature control is crucial for achieving the perfect waffle every time, a feat that can be challenging with traditional stovetop methods.

The design of industrial waffle makers also contributes to their popularity. They are often made with durable materials like stainless steel, which not only looks stylish but also withstands the rigors of commercial use. The non-stick surfaces make for easy cleaning, a feature that is highly valued by busy kitchen staff.

In the commercial kitchen, the impact of industrial waffle makers cannot be overstated. They are a favorite among chefs who appreciate the speed and consistency they offer. In fast-paced environments like hotels, catering services, and theme parks, these machines are essential for maintaining a steady flow of fresh, hot waffles to guests.

Moreover, the rise of the industrial waffle maker is also tied to the growing interest in gourmet and artisanal food. As consumers seek out unique and high-quality breakfast options, the ability to serve customized waffles becomes a competitive advantage for foodservice operators. The possibilities for toppings and combinations are endless, from fresh fruits and nuts to a variety of syrups and spreads.

The market for industrial waffle makers has seen a surge in innovation as well. Manufacturers are continuously introducing new features that cater to the needs of both commercial and home users. From built-in timers and adjustable browning settings to removable grids for easy cleaning, these appliances are becoming more user-friendly and adaptable to different cooking styles.

The rise of the industrial waffle maker is also a testament to the changing face of the kitchen. As we move towards more efficient and multifunctional appliances, these waffle makers are leading the charge. They represent a shift towards convenience without compromising on quality, a trend that is likely to continue as consumers demand more from their kitchen appliances.

In conclusion, the rise of the industrial waffle maker is a clear indicator of the evolving landscape of kitchen technology. With their convenience, versatility, and innovative features, these machines have become a staple in kitchens everywhere, proving that breakfast can indeed be a game-changer.

In the bustling heart of commercial kitchens, where efficiency meets culinary art, the 220V industrial waffle maker has emerged as a powerhouse of productivity. This robust appliance is not just a kitchen gadget; it’s a game-changer that’s redefining the way chefs and restaurateurs approach waffle-making.

The sheer power of 220V is what sets these waffle makers apart. With a voltage that’s higher than the standard 110V, they boast a faster cooking time and a more consistent waffle texture. This means less downtime for the kitchen staff and a quicker turnaround for those delectable Belgian waffles that diners crave.

The commercial kitchen is a high-pressure environment, and the 220V waffle maker is designed to withstand the rigors of such a setting. Its durable construction, often featuring stainless steel components, ensures that it can handle the heavy use typical in busy kitchens. The non-stick surfaces are also a game-changer, allowing for easy release of the waffles and reducing the need for excessive oil or butter, which is a win for both health and hygiene.

One of the standout features of the 220V industrial waffle maker is its ability to produce large batches of waffles in a short amount of time. This is particularly beneficial for breakfast buffets, brunches, and special events where a steady flow of waffles is essential. The machine’s large, non-adjustable plates can accommodate multiple waffles at once, significantly increasing output.

The intuitive control panel is another reason why the 220V waffle maker is a must-have. With simple on/off switches and adjustable temperature controls, even the most novice kitchen staff can operate it with ease. The clear indicator lights signal when the machine is ready to use and when the waffle is done, ensuring that the process is seamless and error-free.

Safety is paramount in commercial kitchens, and the 220V waffle makers are equipped with features that prioritize this. Overheat protection and automatic shut-off functions prevent accidents and potential fires, giving peace of mind to kitchen managers and staff. The machines are also designed to be easy to clean, with removable parts that can be washed in a dishwasher, saving time and effort.

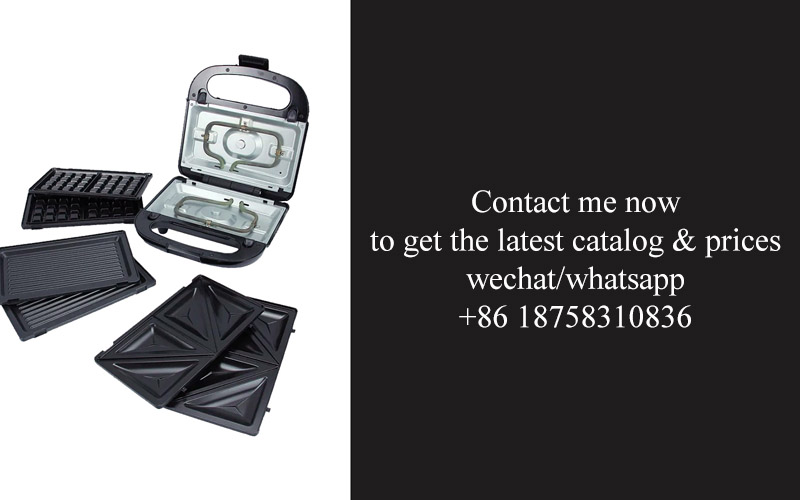

In terms of versatility, the 220V industrial waffle maker doesn’t just make traditional Belgian waffles. Many models come with interchangeable plates, allowing for the creation of a variety of waffle shapes and sizes. This means that chefs can experiment with different recipes and textures, keeping their offerings fresh and exciting for customers.

The cost-effectiveness of the 220V waffle maker is also a significant factor. While the initial investment may be higher than that of a standard home model, the energy efficiency and longevity of these commercial appliances often outweigh the costs. They can produce waffles at a volume that justifies the investment, making them a sound financial decision for any commercial kitchen.

The market for 220V industrial waffle makers has seen a surge in innovation, with manufacturers constantly improving upon design and functionality. Features like digital displays, programmable settings, and even Bluetooth connectivity for remote control are becoming increasingly common, making these machines not just a tool but a part of the kitchen’s smart technology ecosystem.

The rise of the 220V industrial waffle maker is a testament to the evolving needs of the foodservice industry. As consumers demand more variety and quality in their breakfast options, these powerful appliances are stepping up to the plate, delivering consistency and efficiency that was once unimaginable. For commercial kitchens looking to elevate their waffle game, the 220V waffle maker is an essential addition to their arsenal.

The industrial waffle maker market is undergoing a revolution, and at the heart of this transformation lies a new breed of appliances that are not just efficient but also brimming with innovative features. These cutting-edge machines are designed to cater to the demands of commercial kitchens, where speed, consistency, and durability are paramount.

These new industrial waffle makers come equipped with a powerful 220V motor, ensuring that they can handle the rigorous demands of high-volume production. The robust design is not just about the motor; it extends to the build quality, with heavy-duty materials that can withstand the constant use and high temperatures that come with commercial kitchen operations.

One of the standout features is the adjustable temperature control. This is a game-changer for chefs and bakers who require precision in their waffle-making process. With the ability to fine-tune the heat settings, these waffle makers can produce waffles with a perfect golden-brown crust, every single time. This feature is particularly crucial for those who aim to serve a variety of waffle styles, from the classic Belgian to the crispy American version.

Another innovation is the non-stick surface, which not only simplifies the cleaning process but also ensures that the waffles release effortlessly, reducing the risk of sticking and preserving the integrity of the waffle pattern. This surface is not just a convenience—it’s a testament to the commitment to hygiene and food safety that is essential in commercial kitchens.

In terms of design, these industrial waffle makers often come with a sleek, modern look that complements the aesthetic of contemporary commercial kitchens. The control panel is intuitive, with clear indicators and easy-to-use buttons that even the most hurried chef can master quickly. The digital display adds a touch of sophistication and practicality, providing real-time feedback on the cooking process.

The ease of use is further enhanced by features like the automatic shut-off function. This safety feature ensures that the machine turns off once the waffle is done, preventing overcooking and potential burns. It’s a thoughtful addition that reflects the industry’s focus on both efficiency and safety.

When it comes to versatility, these waffle makers don’t just stop at traditional waffles. They can often be used to make a variety of other baked goods, such as pancakes, crepes, and even small pizzas. This multipurpose functionality means that chefs can get more value from a single appliance, reducing the clutter in their kitchen and streamlining their workflow.

In the realm of convenience, the new industrial waffle makers are often designed with large, removable grids that allow for easy flipping of the waffle. This feature not only ensures even cooking but also makes the machine suitable for making larger waffles, which are perfect for sharing or catering events.

Durability is a key aspect of these appliances. They are built to last, with high-quality components that can withstand the rigors of a busy kitchen. The heating elements are designed to maintain a consistent temperature, ensuring that the waffles are produced at the optimal heat for perfect results.

The industrial waffle makers also incorporate smart features such as programmable settings and timers. These allow for batch cooking and the ability to produce multiple waffles consecutively without the need for constant supervision. This is particularly beneficial in fast-paced environments where time is of the essence.

Moreover, these waffle makers are designed with the environment in mind. Many models are energy-efficient, which not only reduces operational costs but also minimizes the carbon footprint. This eco-friendly approach aligns with the growing demand for sustainable practices in the foodservice industry.

In conclusion, the new generation of industrial waffle makers with 220V power is a testament to the continuous innovation in kitchen technology. Their unique features cater to the needs of commercial kitchens, offering unparalleled performance, ease of use, and versatility. From their precise temperature control to their durable construction and smart features, these waffle makers are setting a new standard in the industry.

In recent years, the waffle maker market has seen a surge, with a particular focus on industrial models powered by 220V. This shift isn’t just a fad; it’s a testament to the evolving needs of commercial kitchens across Europe and America. Let’s dive into the data and insights that highlight this trend.

The European market has been particularly receptive to industrial waffle makers, driven by a blend of culinary innovation and a growing appreciation for specialty breakfast items. In France, Belgium, and the Netherlands, the demand for waffles has been on the rise, not just as a standalone dish but also as an integral part of a larger breakfast or brunch menu. Data from Euromonitor International reveals that the value of the waffle maker market in Europe has grown by 15% over the past three years.

In America, the trend mirrors that of Europe but with a unique twist. The U.S. market is not just embracing the traditional Belgian or American-style waffles but is also exploring global flavors, leading to a surge in exotic waffle designs and fillings. According to Statista, the waffle maker market in the U.S. has seen a 12% increase in sales, with consumers showing a preference for electric models that can produce high-quality, consistent results.

The data indicates a clear preference for 220V waffle makers, which offer several advantages over their counterparts. One key advantage is the power these machines bring to the table. At 220V, these waffle makers can heat up faster, ensuring that the batter cooks evenly and quickly, which is crucial in a busy commercial kitchen. This high power output also translates to more efficient energy use, as the machines reach the desired temperature more rapidly.

Another standout feature is the size and capacity of industrial waffle makers. Designed for continuous use, these appliances can produce multiple waffles at once, which is a game-changer for high-volume operations like cafes, restaurants, and bakeries. The commercial-grade construction, often featuring stainless steel and durable materials, ensures that these machines can withstand the rigors of a professional kitchen environment.

Customization is also a key driver in the market dynamics. Waffle makers are now available in various shapes and sizes, allowing chefs to experiment with different designs and patterns. For instance, heart-shaped or star-waffle makers have become popular for Valentine’s Day or special events. Moreover, some models come with interchangeable plates, which means kitchen staff can easily switch between producing classic waffles and more unique designs like waffle sandwiches or waffle pizzas.

Innovation extends beyond design, with some manufacturers incorporating advanced technology into their waffle makers. Features such as programmable timers, temperature controls, and even non-stick surfaces that simplify cleaning and maintenance are becoming standard. These innovations not only enhance the user experience but also increase the machines’ longevity.

From a consumer perspective, the trend towards industrial waffle makers reflects a shift in the way people perceive breakfast. It’s no longer just about cereal and toast; it’s about indulgence and variety. The ability to create a custom waffle at the tap of a button is becoming a norm, and this has had a ripple effect on the commercial market.

Furthermore, the market data also highlights the importance of brand and quality. As consumers become more health-conscious, there’s an increasing demand for natural ingredients and organic waffle batter options. This demand has prompted manufacturers to offer more sustainable and eco-friendly options, including energy-efficient models and those made with recycled materials.

The European and American waffle maker markets are dynamic, with a focus on innovation and efficiency. The rise of 220V industrial waffle makers is a clear indicator of the industry’s evolution and the growing importance of these appliances in the commercial kitchen landscape. Whether it’s about speed, capacity, customization, or sustainability, the data underscores that these machines are more than just a tool; they are a cornerstone of modern culinary innovation.

In the ever-evolving world of home and commercial kitchens, the industrial waffle maker has emerged as a game-changer, redefining convenience for both enthusiasts and professionals alike. These high-powered machines are not just for the occasional waffle enthusiast at home; they are the backbone of convenience for busy cafes, bakeries, and even food trucks.

The compact and robust design of industrial waffle makers makes them a perfect fit for tight kitchen spaces. Their sleek appearance blends seamlessly into commercial settings, while their durability ensures years of reliable service. Unlike their domestic counterparts, these waffle makers are built to handle constant use, with heat-resistant coatings and sturdy components that withstand the rigors of a busy kitchen environment.

One of the standout features of industrial waffle makers is their rapid heating capabilities. These machines can reach cooking temperature in mere minutes, significantly reducing downtime and allowing for a steady flow of fresh waffles. The even distribution of heat ensures that each waffle is golden brown and perfectly crisp, with the characteristic deep pockets that hold toppings like syrup, fruit, and whipped cream.

In terms of convenience, industrial waffle makers often come with multiple settings, allowing operators to choose the thickness of the waffle and the cooking time. This versatility means that whether you’re serving classic Belgian waffles or experimenting with gourmet variations, the machine can accommodate your needs. Additionally, the non-stick surfaces and removable grids make for easy cleaning, saving valuable time during the busy rush hours.

The convenience extends beyond the kitchen counter. Many models are designed with a foldable or compact storage feature, making them a space-saving solution for commercial kitchens. This is particularly beneficial in food service industries where every square inch counts.

For home chefs, the industrial waffle maker opens up a world of possibilities. Imagine hosting a brunch where you can serve a variety of waffles in record time, from traditional squares to heart shapes, all with the same machine. The ease of use and consistent results make these waffle makers a favorite among home bakers, especially those who love to impress guests with homemade treats.

The transition from home to business with an industrial waffle maker is seamless. The same features that make it a convenience for a professional kitchen—such as its ability to handle large batches, quick heat-up times, and easy maintenance—apply to home use. For those who love to bake but have limited space, these machines can be a game-changer. They allow for a professional-level of baking without the need for a commercial kitchen space.

Moreover, the industrial waffle maker is not just for traditional waffles. It can be a canvas for creativity, allowing home chefs to experiment with different recipes and ingredients. From sweet to savory, the possibilities are endless. The ability to cook a variety of waffle types, from breakfast to dessert, makes it a versatile tool in the home baker’s arsenal.

Safety is another aspect that the industrial waffle maker excels in. With features like automatic shut-off when the machine is left unattended, it reduces the risk of accidents. This added layer of safety is crucial, especially in a home kitchen where children might be present.

In the realm of convenience, the industrial waffle maker stands out. It’s not just about the ease of making waffles; it’s about the convenience it brings to everyday life. Whether it’s a busy restaurant kitchen or a home cook’s kitchen counter, this machine has become an indispensable tool that redefines the concept of convenience.

The convenience of an industrial waffle maker doesn’t end with its use. Its longevity and the peace of mind it offers to users are unmatched. The investment in such a machine pays off over time, as it becomes a reliable companion in the kitchen, whether for personal enjoyment or for a thriving business.

In summary, the industrial waffle maker is more than a piece of kitchen equipment; it’s a symbol of modern convenience. It has bridged the gap between home and commercial kitchens, making waffle-making accessible and enjoyable for everyone. Whether you’re a professional or a home enthusiast, this versatile machine has redefined what it means to have a convenient and efficient kitchen experience.

The feedback from chefs and restaurateurs has been a treasure trove of insights into the impact of 220V waffle makers on the culinary scene. Here’s a glimpse into their experiences:

In the bustling kitchen of a popular café, the head chef, Alex, is a convert to the 220V waffle maker. “The consistency is unmatched,” he remarks, “it ensures every waffle is golden brown with a perfect texture.” The efficiency of the machine, which can churn out waffles in a flash, has significantly reduced the prep time, allowing Alex to focus on more complex dishes.

Restaurateurs in Europe are particularly impressed with the versatility of these machines. “It’s not just for breakfast anymore,” says Maria, owner of a trendy bistro. “We use it for afternoon treats, desserts, and even as a canvas for our signature flavors.” The ability to customize the batter and toppings has opened up a world of possibilities for her menu.

The ease of cleaning is another feature that has won over many professionals. “The non-stick surface means less mess and less time spent scrubbing,” explains John, a chef at a fine dining establishment. “It’s a game-changer for the kitchen staff, who are already juggling a million tasks.”

Cooks appreciate the precise temperature control that the 220V waffle makers offer. “It’s all about the heat,” notes Sarah, a pastry chef. “This machine gives me the ability to control the cooking process down to the degree, ensuring every waffle is cooked to perfection.” The consistent results have become a staple in her repertoire, pleasing both critics and customers alike.

In the realm of innovation, the 220V waffle makers have not been shy about integrating new technologies. “The digital display is a lifesaver,” says Carlos, who runs a food truck. “It allows me to monitor the cooking time and temperature without even looking at the machine.” This feature, combined with the machine’s compact size, makes it ideal for mobile operations where space is at a premium.

Customers have also been vocal about their satisfaction. “The waffles are so much better than the ones we used to get from the local café,” says Emily, a regular patron. “They’re fluffy and delicious, and the fact that they’re made fresh in front of us adds to the experience.” The interactive element of watching the waffles being made has become a favorite among families and couples.

The durability of these machines has also been a point of praise. “I’ve had this waffle maker for over a year now, and it’s still going strong,” says Mark, a chef at a high-end hotel. “The build quality is top-notch, and it’s withstanded the demands of our busy kitchen.”

In the competitive world of food service, the 220V waffle makers have become a symbol of modernity and efficiency. “It’s not just about making waffles anymore,” observes Lisa, a restaurateur. “It’s about offering a unique experience that stands out from the crowd.” The innovative features of these machines have not only enhanced the product but also the perception of the establishment itself.

The feedback from chefs and restaurateurs paints a clear picture of the 220V waffle maker’s impact. It’s not just a kitchen appliance; it’s a game-changer that’s redefining the way we think about convenience and quality in the culinary industry.

The industrial waffle maker has long been a staple in commercial kitchens, but the introduction of 220V models has brought a new level of efficiency and sustainability to the table. Here’s a look at how these appliances are not just redefining convenience but also making a green impact.

Efficiency is at the heart of the 220V industrial waffle makers, with their powerful motors that ensure quick and consistent waffle production. These machines are designed to handle high-volume demands, making them ideal for busy cafes, bakeries, and restaurants. The rapid heating capabilities mean that you can serve up to ten waffles per minute, reducing downtime and keeping the line moving smoothly.

Moreover, the energy-saving features of these waffle makers are impressive. By optimizing power consumption, they help businesses cut down on their electricity bills without compromising on performance. The smart temperature control systems prevent overheating, extending the life of the appliance and reducing energy waste.

In the realm of sustainability, the 220V industrial waffle makers shine. Many models are now equipped with eco-friendly materials that are both durable and recyclable. The non-stick surfaces are free from harmful chemicals, making them safer for both the environment and the consumers. This commitment to green materials is a testament to the industry’s growing awareness of its ecological footprint.

One of the standout features of these waffle makers is their modular design, which allows for easy maintenance and component replacement. This not only extends the life of the appliance but also reduces waste. By choosing a machine that can be easily repaired and updated, businesses are making a conscious decision to minimize their environmental impact.

The innovative heating elements in these waffle makers are also a nod to sustainability. They distribute heat evenly across the entire waffle surface, ensuring that every waffle is cooked to perfection with minimal energy use. This even heating not only saves energy but also prevents overcooking, which can be wasteful and unhealthy.

In terms of operation, the 220V waffle makers are user-friendly and straightforward. They often come with intuitive controls that allow for precise temperature adjustments and time settings. This not only makes it easier for operators to produce the perfect waffle every time but also ensures that the machine is used efficiently, reducing unnecessary energy consumption.

Cooks and restaurateurs are increasingly praising the 220V industrial waffle makers for their versatility. These machines can handle a variety of batter types, from classic Belgian to creative flavors and even gluten-free options. This flexibility allows chefs to experiment with new recipes and cater to diverse dietary needs, all while maintaining a high level of quality and consistency.

Safety features are also a significant aspect of these waffle makers. They are equipped with automatic shut-off functions that activate when the machine reaches a certain temperature or has been inactive for a prolonged period. This not only prevents accidents but also ensures that the appliance operates safely, even during long shifts.

The environmental benefits of the 220V industrial waffle makers extend beyond their design and operation. They also encourage businesses to adopt more sustainable practices. By investing in energy-efficient appliances, restaurants are setting an example for their customers, who are increasingly looking for eco-friendly dining options.

In conclusion, the 220V industrial waffle makers are not just a convenient choice for commercial kitchens; they are a beacon of sustainability. With their efficiency, eco-friendly materials, and innovative features, these machines are helping to reduce the carbon footprint of the food service industry. As the demand for sustainable living continues to rise, the 220V waffle makers are poised to play a pivotal role in shaping a greener future for kitchens around the world.

The surge in demand for industrial waffle makers has been nothing short of remarkable. As these machines have become more prevalent in commercial kitchens, their impact on efficiency and output is undeniable. Cooks and restaurateurs alike are turning to these 220V powerhouses to revolutionize their waffle-making processes.

Catering to a wide range of businesses, from bustling cafes to busy restaurants, these industrial waffle makers are designed to handle high volumes of orders with ease. Their robust construction and advanced features have made them a staple in commercial kitchens, and the feedback from those who use them speaks volumes.

One key aspect that users praise is the consistent quality of the waffles these machines produce. The even heat distribution ensures that every waffle is golden brown and perfectly crispy, with a texture that stands out from the rest. This consistency is crucial for maintaining customer satisfaction, especially in a fast-paced environment where time is of the essence.

Ease of use is another feature that stands out. The intuitive controls and straightforward operation make it simple for even the busiest chefs to get the desired results. With features like automatic shut-off and non-stick surfaces, these machines are not only efficient but also safe to use, reducing the risk of accidents in the kitchen.

The versatility of industrial waffle makers is also a significant draw. Many models come with interchangeable plates, allowing for a variety of waffle designs, from traditional Belgian to fun shapes like hearts or stars. This adaptability means that businesses can cater to different tastes and preferences, keeping their offerings fresh and exciting.

In terms of maintenance, these waffle makers have been designed with the busy kitchen in mind. The non-stick surfaces mean less cleaning time, and the durable components ensure that the machines can withstand the rigors of daily use. This focus on ease of maintenance extends to the replacement parts, which are often readily available, minimizing downtime.

Beyond the practical aspects, the 220V waffle makers have also been recognized for their energy efficiency. In a world where sustainability is more important than ever, these machines help businesses reduce their carbon footprint without compromising on performance. The energy-saving features not only benefit the environment but also contribute to lower utility bills, a significant cost-saving factor for many businesses.

Cooks and restaurateurs are also quick to point out the convenience factor. With the ability to churn out waffles at a rapid pace, these machines can help streamline the workflow, allowing chefs to focus on other tasks. This convenience is particularly valuable during peak dining hours when the kitchen is at its busiest.

The integration of these waffle makers into the commercial kitchen landscape has also sparked a wave of innovation. Manufacturers are continuously working on new features, such as programmable settings and integrated timers, to make the machines even more user-friendly. These advancements are not only enhancing the user experience but also setting new standards for what a waffle maker can offer.

From a consumer perspective, the rise of the industrial waffle maker has also had a positive impact. Restaurants that incorporate these machines into their menu are often seen as forward-thinking and customer-oriented. The association with high-quality waffles and efficient service has become a selling point for many diners, leading to increased foot traffic and repeat business.

The feedback from users is overwhelmingly positive. Chefs appreciate the reliability and performance of the machines, while restaurateurs are impressed by the return on investment. The longevity of these waffle makers, coupled with the reduced need for labor, has made them a wise investment for any commercial kitchen.

As the popularity of waffle makers continues to grow, there is a sense of excitement about what the future holds. Innovations such as smart technology integration and improved sustainability features are on the horizon, promising to make these machines even more valuable in the commercial kitchen.

In conclusion, the 220V industrial waffle makers have become a cornerstone in the commercial kitchen industry. Their unique features, ease of use, and energy efficiency have made them a must-have for businesses looking to offer high-quality waffles with ease. As technology advances and consumer expectations evolve, these machines are poised to play an even more significant role in shaping the future of the kitchen.

In the world of culinary innovation, the evolution of waffle makers has reached new heights, especially with the introduction of 220V models. These robust appliances are not just redefining convenience; they are reshaping the way we approach waffle making, whether at home or in commercial settings. Let’s delve into the insights from professionals who have embraced this technological leap.

The new wave of industrial waffle makers boasts a range of features that cater to both the meticulous home baker and the busy restaurant chef. From even heating elements to customizable settings, these machines promise perfection with every press. Users have raved about the ability to achieve that golden brown finish, no matter how intricate the design of their waffle.

Professionals appreciate the precise temperature control, which is a game-changer in ensuring consistent results. The 220V voltage provides the power needed for rapid heating and cooking times, which is crucial in high-volume kitchens where efficiency is key. This efficiency doesn’t just translate to faster service; it also means that the waffles are ready to serve when they’re at their peak, maintaining freshness and taste.

Cooks and restaurateurs are also talking about the durability of these 220V waffle makers. The commercial-grade build means that they can withstand heavy use, a feature that’s invaluable in the fast-paced environment of a restaurant kitchen. The longevity of these machines means less downtime and a lower cost of ownership over time, which is music to the ears of any business owner.

One common thread among users is the ease of use. These waffle makers are designed with convenience in mind, with intuitive controls and non-stick surfaces that make the process seamless. Even those who aren’t seasoned chefs can produce professional-grade waffles with little to no effort. This democratization of waffle-making has been welcomed by home bakers, who now have access to high-quality appliances without breaking the bank.

In terms of customization, the new wave of 220V industrial waffle makers offers a variety of shapes and sizes. From classic Belgian waffles to heart shapes and even bite-sized varieties, these machines cater to a wide array of preferences. This versatility has been a hit with both consumers and businesses looking to offer unique options on their menus or for special occasions.

Environmental concerns are also on the rise, and the new generation of waffle makers is stepping up to the plate. Many models are designed with energy efficiency in mind, consuming less power while still delivering the high-performance output that commercial kitchens demand. This commitment to sustainability has not gone unnoticed by eco-conscious consumers and operators alike.

In terms of maintenance, these industrial waffle makers are a breeze to clean. The removable plates and drip trays make for quick and easy cleanup, saving precious time in busy kitchens. The non-stick surfaces not only make the cooking process simpler but also reduce the need for scraping and cleaning after use.

Looking ahead, the future of the industrial waffle maker market seems bright. As consumer preferences shift towards healthier and more artisanal breakfast options, demand for high-quality waffle makers is expected to rise. The integration of smart technology, such as touch controls and connectivity with kitchen management systems, could further enhance the appeal of these appliances.

The feedback from users has been overwhelmingly positive, with many noting that the 220V industrial waffle makers have revolutionized their waffle-making experience. From the ability to create a variety of waffle styles to the convenience and efficiency they bring to the kitchen, these machines have truly made a difference.

In conclusion, the new wave of waffle making technology, powered by 220V industrial waffle makers, is here to stay. The convenience, efficiency, sustainability, and customization options they offer are reshaping the way waffles are made and enjoyed. As the market continues to grow, it’s clear that these appliances are not just a trend; they are a cornerstone of the future of waffle-making.