Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

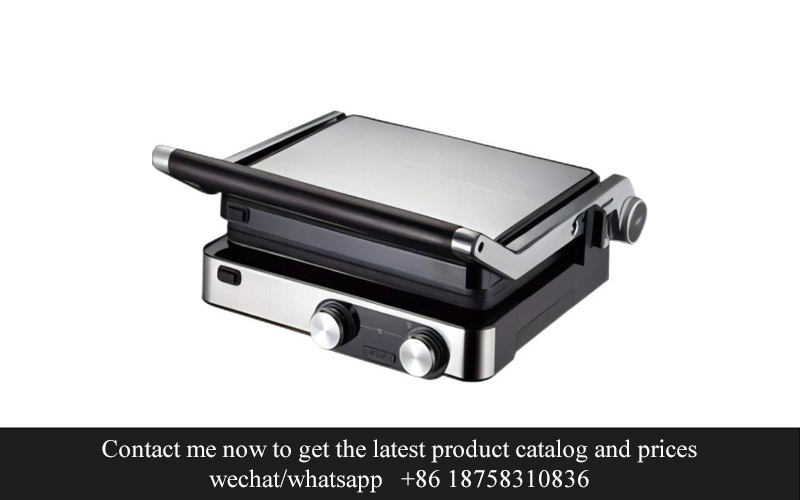

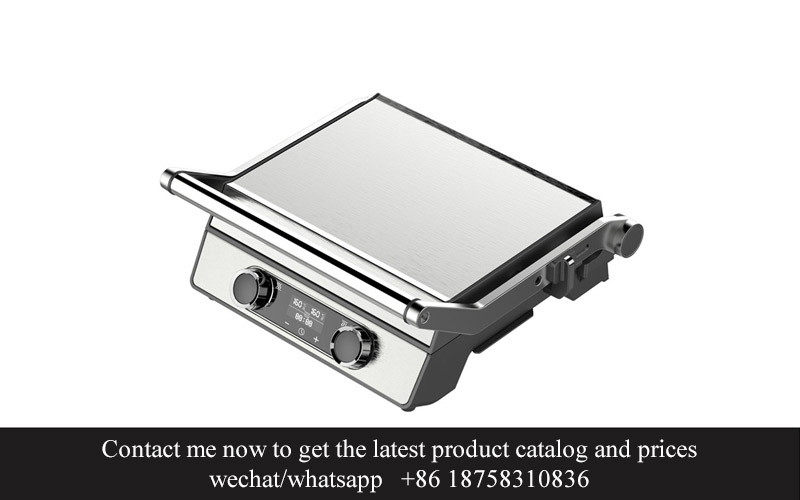

In today’s fast-paced culinary landscape, the demand for efficiency and quality in commercial kitchens is at an all-time high. Enter the NSF approved commercial sandwich press, a versatile and innovative tool that’s redefining the art of sandwich-making. This compact powerhouse is not just a kitchen gadget; it’s a game-changer that promises to elevate the sandwich experience to new heights. As we delve into the world of these presses, it becomes clear that embracing the NSF approved commercial sandwich press is a strategic move for any establishment aiming to thrive in the competitive food industry.

In recent years, the commercial sandwich press has quietly emerged as a game-changer in the culinary landscape. Once a staple in diners and casual eateries, these versatile appliances are now revolutionizing the way kitchens of all sizes handle sandwich preparation. The rise of the commercial sandwich press can be attributed to several key factors that have made it an indispensable tool for chefs and restaurateurs alike.

Firstly, the demand for convenience has surged in the fast-paced world we live in. Customers are increasingly seeking quick and efficient service, and the commercial sandwich press delivers on this front with unparalleled speed. These presses can produce perfectly toasted sandwiches in a matter of minutes, reducing wait times and improving customer satisfaction.

Secondly, the versatility of the commercial sandwich press cannot be overstated. Whether you’re crafting classic American sandwiches, gourmet fusion creations, or even gluten-free options, these presses are designed to accommodate a wide range of ingredients and bread types. From brioche to ciabatta, from ham and cheese to avocado and egg, the possibilities are virtually endless.

Moreover, the commercial sandwich press has become a favorite among health-conscious consumers. With the growing trend towards healthier eating habits, these presses offer the option to toast bread to a preferred level of crispiness, allowing for better control over the nutritional content of the final product. This feature is particularly appealing to those looking to incorporate more whole grains and fiber into their diet.

The technology behind commercial sandwich presses has also seen significant advancements. Modern models are equipped with adjustable heat settings, ensuring that every sandwich is toasted to the perfect level of doneness. Some presses even come with features like non-stick surfaces, which make cleaning a breeze and reduce the risk of burnt edges.

In addition to technological improvements, the commercial sandwich press has also gained popularity due to its ease of use. These appliances are typically designed with user-friendly controls and can be quickly cleaned and maintained. This makes them a practical choice for busy kitchens where efficiency is key.

Another factor contributing to the rise of the commercial sandwich press is its cost-effectiveness. While high-quality commercial appliances can be an investment, the long-term savings on labor and the ability to serve a higher volume of sandwiches at a faster pace often outweigh the initial cost. For small to medium-sized businesses, this can be a significant advantage in a competitive market.

Restaurants and cafes that have embraced the commercial sandwich press have seen a variety of benefits. For example, a popular sandwich shop reported a 20% increase in sales after introducing a new line of press-equipped sandwiches. This growth can be attributed to the appeal of the product itself, as well as the speed and consistency it offers.

Furthermore, the commercial sandwich press has become a centerpiece for many kitchen displays. Its sleek design and the visible cooking process can be a draw for customers, turning the sandwich-making experience into an interactive and engaging one. This not only adds to the visual appeal of the establishment but also creates a sense of theatre that can enhance the dining experience.

As the food industry continues to evolve, the commercial sandwich press has become a symbol of adaptability and innovation. Chefs are now experimenting with different flavors and ingredients, pushing the boundaries of what a sandwich can be. This has led to a proliferation of unique and seasonal sandwich offerings, further fueling the popularity of the commercial sandwich press.

In conclusion, the rise of the commercial sandwich press in the kitchen is a testament to the changing demands of consumers and the evolving landscape of the food service industry. With its ability to deliver high-quality, customized sandwiches at a rapid pace, this appliance has become a must-have for any establishment looking to stay ahead in the competitive world of quick-service dining.

In the bustling world of commercial kitchens, where efficiency and quality are paramount, the NSF (National Sanitation Foundation) approval has become a beacon of trust and reliability. This stamp of approval is not just a certification; it’s a comprehensive assessment that ensures products meet stringent safety and quality standards. Understanding what NSF approval entails is crucial for anyone looking to invest in kitchen equipment, especially commercial sandwich presses.

NSF approval is a rigorous process that involves thorough evaluations of a product’s design, materials, manufacturing processes, and its ability to prevent contamination. It’s important to note that NSF does not test products itself but rather certifies that they meet the established standards. Here’s a deeper dive into what this approval means:

The first aspect of NSF approval is the material safety. NSF ensures that all materials used in the construction of a commercial sandwich press are non-toxic and do not leach harmful chemicals into the food. This is particularly critical in the sandwich-making industry, where the press comes into direct contact with ingredients.

Secondly, NSF certification requires that the sandwich press be capable of withstanding high temperatures without warping or deforming. This is crucial for maintaining both the integrity of the sandwich and the safety of the kitchen staff. The ability to maintain consistent heat is also essential for ensuring that the food is cooked to a safe temperature.

Thirdly, NSF pays close attention to the design and construction of the sandwich press to ensure it is easy to clean and sanitize. In a commercial kitchen, cleanliness is not just a best practice; it’s a legal requirement. The approval process includes a thorough review of the press’s design to make sure it doesn’t have any crevices or hard-to-reach areas where bacteria can hide.

Additionally, NSF considers the ergonomics of the sandwich press. A well-designed tool not only makes food preparation more efficient but also reduces the risk of injury to kitchen staff. The certification process includes an evaluation of the press’s weight, handle design, and overall ease of use.

One of the most important aspects of NSF approval is the pressure mechanism of the sandwich press. The certification ensures that the press applies consistent pressure to create evenly cooked sandwiches, which is essential for both quality and safety. Inconsistent pressure can lead to uneven cooking, potentially harboring harmful bacteria.

Safety is paramount in commercial kitchens, and NSF approval takes this into account by ensuring that the sandwich press is built to prevent electrical hazards. This includes testing for electrical leakage and ensuring that the press meets all relevant electrical safety standards.

Furthermore, NSF certification covers the manufacturing process itself, ensuring that the sandwich press is made with quality control measures in place. This includes regular inspections, adherence to manufacturing standards, and the use of quality components throughout the production process.

Understanding NSF approval also means recognizing the ongoing commitment to safety and quality that certified manufacturers make. Once a product is certified, the manufacturer must continue to comply with NSF’s stringent standards, undergo periodic audits, and maintain a high level of quality control.

In conclusion, NSF approval is not just a one-time achievement; it’s a continuous process. For commercial sandwich presses, this means that the manufacturer is committed to maintaining the highest level of safety and quality in every unit produced. For consumers and businesses, this certification is a reassurance that the sandwich press they are investing in is reliable, safe, and built to last. It’s a mark of quality that stands out in a competitive market, providing peace of mind to those who rely on these tools to deliver delicious and safe sandwiches to their customers.

In the bustling world of commercial kitchens, where efficiency and safety are paramount, selecting the right sandwich press can make all the difference. When looking for an NSF approved commercial sandwich press, there are several key features to consider that ensure both quality and safety:

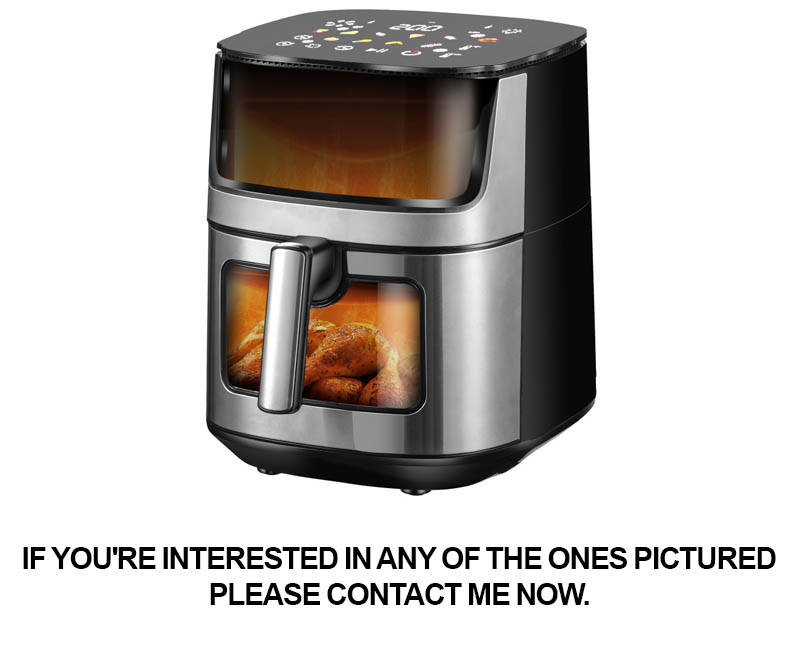

The first aspect to consider is the build quality of the sandwich press. Look for a robust construction with high-grade materials. Stainless steel is a common choice for its durability and resistance to corrosion, ensuring that the press withstands the demands of a busy kitchen environment.

The heating elements are crucial for consistent sandwich pressing. An NSF approved commercial sandwich press should have a reliable heating system that evenly distributes heat across the surface. Look for models with precise temperature controls, as this allows for consistent outcomes, whether you’re making classic grilled cheese or gourmet paninis.

Non-stick surfaces are a must-have feature in a commercial sandwich press. This not only makes clean-up easier but also prevents food from sticking to the plates, which can be a major concern in high-volume kitchens. The non-stick coating should be of high quality to ensure it doesn’t wear off over time.

Safety features are non-negotiable when it comes to commercial kitchen equipment. An NSF approved sandwich press should have an automatic shut-off feature to prevent overheating and potential burns. Additionally, the design should include cool-touch handles and surfaces to minimize the risk of accidents.

Ease of use is another critical factor. The sandwich press should have a straightforward operation, with clear controls that are easy to access and understand. Look for models with adjustable pressure settings, allowing you to customize the cooking intensity to your specific recipes and preferences.

A compact design can be a significant advantage in a commercial kitchen, where space is often limited. A sandwich press that takes up minimal counter space allows for more room for other appliances and ingredients. However, compactness should not compromise the press’s ability to handle the volume of food required in a commercial setting.

The ability to accommodate different sizes of sandwiches is important. A versatile sandwich press can handle a range of bread types and sizes, from small sliders to large, hearty paninis. This flexibility ensures that you can cater to a diverse customer base with varying preferences.

A built-in timer can be a game-changer in a fast-paced kitchen. It allows for precise control over cooking times, ensuring that sandwiches are cooked to perfection every time. This feature can help streamline your workflow and reduce the likelihood of overcooking or undercooking.

In a commercial setting, maintenance is key to keeping your equipment running smoothly. An NSF approved sandwich press should be easy to clean, with removable parts that can be washed in a dishwasher or by hand. This feature not only saves time but also ensures that your sandwich press remains hygienic and ready for use.

Durability is a given in a commercial sandwich press. It should be designed to handle heavy use without losing its performance. Look for brands that offer warranties, indicating confidence in the longevity of their products.

Lastly, consider the brand reputation and customer reviews. An NSF approved sandwich press from a reputable manufacturer is more likely to meet your expectations in terms of quality and reliability. Reading through customer reviews can provide insights into the real-world performance of the product.

By focusing on these features, you can ensure that the sandwich press you choose is not only NSF approved but also a valuable asset to your commercial kitchen, delivering both quality sandwiches and peace of mind.

In today’s fast-paced culinary landscape, the NSF approved commercial sandwich press stands out not just for its functionality but also for its innovative designs and features that set it apart from the competition. Here’s a closer look at what makes these sandwich presses a game-changer in the commercial kitchen:

The sleek and modern design of the NSF sandwich press is not just about aesthetics; it’s a reflection of its efficiency. With compact dimensions that are perfect for countertop space, these presses can easily be integrated into any kitchen setup, from bustling cafes to busy restaurants. The ergonomic handles make it a breeze to operate, ensuring that even less experienced staff can quickly master the art of crafting perfect sandwiches.

One of the standout features of the NSF sandwich press is its adjustable heat control. This isn’t just about consistency in sandwich toasting; it’s about versatility. From the lightest of toasts to the darkest, the precise heat settings allow chefs to cater to a wide range of preferences. This control also extends to the pressing pressure, which can be adjusted to ensure that each sandwich is uniformly pressed, holding together perfectly and achieving the ideal texture.

The non-stick surfaces of these sandwich presses are not just convenient for clean-up; they’re also a testament to their longevity. The smooth, durable surfaces prevent food from sticking, reducing the need for frequent maintenance and minimizing wear and tear. This not only saves time but also ensures that the press delivers high-quality sandwiches every time.

The inclusion of safety features is another area where these presses excel. Many models come equipped with automatic shut-off functions that kick in if the press is left unattended, reducing the risk of fire and ensuring peace of mind for both chefs and customers. Additionally, the cool-to-the-touch exteriors mean that there’s no risk of burns, even after extended use.

Innovative heating elements within the press ensure even distribution of heat, eliminating cold spots and hot spots that can result in unevenly toasted sandwiches. The rapid heating capabilities mean that the press is ready to use almost instantly, reducing downtime and keeping the line moving smoothly.

The NSF sandwich press also boasts a variety of features that enhance its functionality. Some models come with removable drip trays that catch any excess moisture, preventing messes and keeping the workspace clean. Others have built-in timers that allow for precise control over the toasting and pressing times, ensuring consistency across every batch.

Another notable feature is the inclusion of different plate designs, from the classic flat top for regular sandwiches to grooved plates for paninis and even convex plates for heartier items. This versatility means that one press can handle a variety of sandwich types, from breakfast to lunch to dinner options.

The innovative use of materials in the construction of these presses is also noteworthy. Lightweight yet robust, these materials not only make the presses easier to handle but also contribute to their longevity. The quality of the build is evident in every aspect, from the sturdy handles to the heavy-duty hinges that ensure years of reliable service.

The attention to detail in the design of the NSF sandwich press is impressive. The thoughtfulness behind every feature, from the user-friendly control panel to the convenient storage space for accessories, reflects a commitment to improving the efficiency and comfort of the operator.

Lastly, the energy-efficient nature of these presses cannot be overstated. With their advanced heating technology, these sandwich presses not only produce perfect sandwiches but also do so with minimal energy consumption, making them an environmentally friendly choice for commercial kitchens.

In summary, the NSF sandwich press is a marvel of modern design and functionality. With its versatile features, user-friendly design, safety features, and innovative heating technology, it’s clear why it stands out from the crowd. Whether it’s in a busy café or a high-end restaurant, the NSF sandwich press is a reliable companion that enhances the quality and speed of sandwich preparation, setting a new standard for commercial kitchen equipment.

In recent years, the demand for quick and convenient food options has surged, and the sandwich has emerged as a favorite among consumers. The rise of fast-casual dining concepts has further propelled this trend, making the NSF-approved commercial sandwich press a crucial tool for any establishment aiming to meet these evolving preferences. Here’s why now is the perfect time to invest in one:

The surge in demand for grab-and-go meals has created a competitive landscape where speed and efficiency are paramount. With an NSF-approved commercial sandwich press, operators can streamline their service and reduce wait times, ensuring a smoother dining experience for customers. This efficiency is especially valuable in high-traffic areas where time is a precious commodity.

Consumers are increasingly health-conscious, seeking balanced meals that are both satisfying and nutritious. An NSF-approved sandwich press allows for customizable sandwiches, where operators can offer a variety of breads, fillings, and condiments, catering to diverse dietary preferences. This flexibility not only satisfies customers but also positions the establishment as a provider of fresh, made-to-order options.

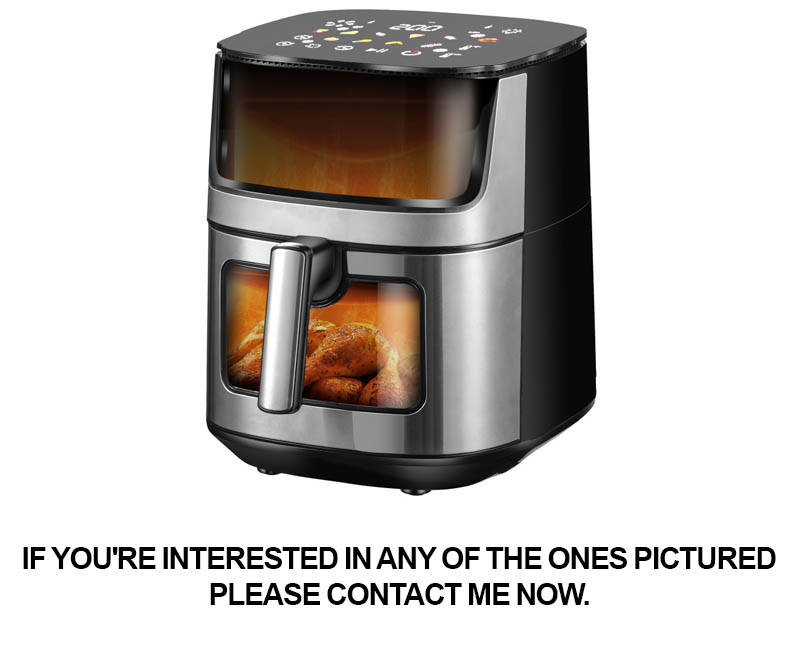

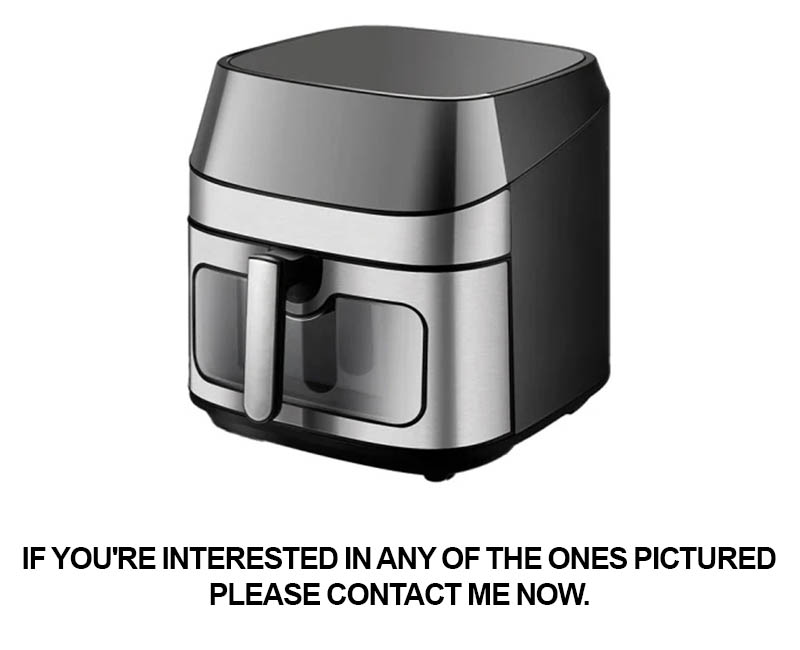

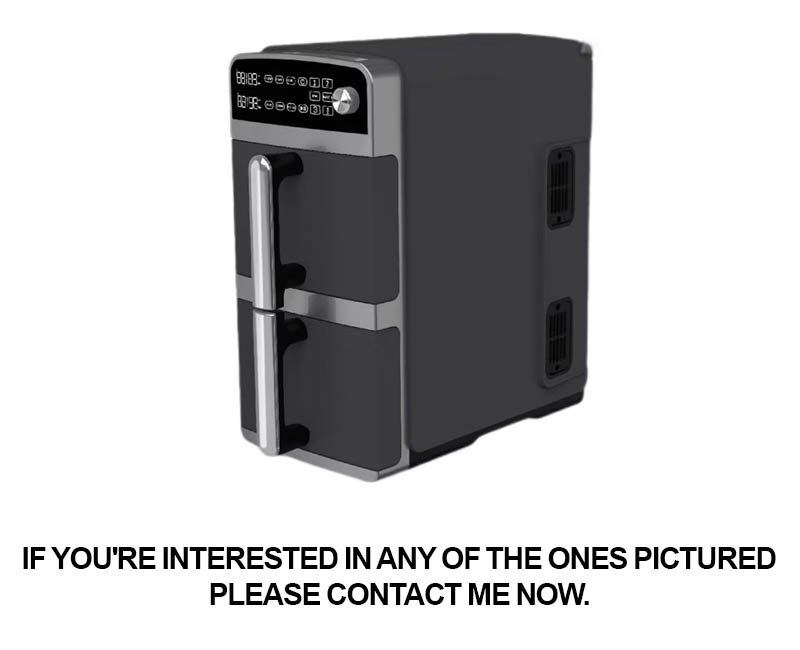

The convenience of a sandwich press extends beyond the kitchen. It’s a versatile tool that can be used to create a range of food items, from breakfast sandwiches to gourmet paninis. This adaptability means that establishments can diversify their menu without the need for multiple specialized appliances, optimizing kitchen space and reducing equipment costs.

In an era where sustainability is a key concern, the use of an NSF-approved sandwich press aligns with eco-friendly practices. These presses are designed for durability, meaning they can withstand heavy use without compromising performance. By investing in a quality sandwich press, businesses contribute to a longer lifespan of their equipment, reducing the need for frequent replacements and the subsequent waste.

The rise of mobile and online ordering platforms has made it easier for customers to place orders from anywhere, at any time. An NSF-approved sandwich press ensures that the food prepared is consistent and of high quality, regardless of the channel through which it’s ordered. This consistency is vital for building a strong brand reputation and fostering customer loyalty.

With the growing popularity of artisanal and gourmet food, the sandwich has become a canvas for creativity. An NSF-approved commercial sandwich press allows chefs to experiment with different cooking temperatures and pressures, resulting in unique textures and flavors. This capability not only attracts food enthusiasts but also sets the establishment apart from competitors.

The technology behind modern sandwich presses has advanced significantly. Features like adjustable heat settings, non-stick surfaces, and rapid heating capabilities ensure that operators can achieve the perfect sandwich every time. These innovations not only improve the quality of the product but also reduce the risk of food waste due to undercooking or overcooking.

The cost-effectiveness of an NSF-approved sandwich press cannot be overstated. Despite the initial investment, the long-term savings from reduced energy consumption, lower maintenance costs, and increased productivity make it a smart financial decision. Moreover, the ability to offer a variety of sandwich options at a competitive price point can lead to higher sales and greater profitability.

In conclusion, the market trends and consumer demand for quick, healthy, and customizable food options make the NSF-approved commercial sandwich press an invaluable asset. By investing in this equipment, businesses can capitalize on current dining trends, enhance customer satisfaction, and achieve operational excellence. The time is ripe for embracing the sandwich press as a cornerstone of modern foodservice.

In a bustling café, the sandwich press stands out as a cornerstone of efficiency, its NSF approval a testament to its reliability. The café’s owner, Mark, has seen a surge in breakfast and lunch sales since the installation. Customers appreciate the consistent, golden-brown toasted sandwiches, a stark contrast to the unevenly toasted fare of the past. The press’s ability to handle high volumes without compromising quality has been a game-changer for the café’s operation.

At a corporate office, the sandwich press has become a favorite among employees during lunch breaks. Its compact design fits seamlessly into the small kitchenette, and its quick-to-heat element ensures that fresh, hot sandwiches are ready in minutes. The convenience has spurred a shift in office culture, with many employees opting for a homemade meal over takeout, thus saving time and reducing waste.

A local sports club has embraced the NSF sandwich press for its post-workout meals. Athletes find the press’s even heating ideal for creating melt-in-your-mouth cheese sandwiches that complement their post-exercise protein needs. The press’s durability and ease of cleaning have made it a staple in the club’s kitchen, ensuring that every meal is both nutritious and satisfying.

A high-end hotel has taken the sandwich press to new heights by using it to craft gourmet sandwiches for guests. The hotel’s executive chef, Maria, has developed a range of sophisticated recipes that highlight the press’s ability to create a perfect crust while keeping the interior tender. The press’s versatility has become a key component in the hotel’s culinary offerings, enhancing the dining experience for guests who seek both quality and convenience.

In a food truck culture that’s rapidly growing, the sandwich press has found its niche. Vendors like Alex, who runs a popular gourmet food truck, rely on the press to deliver high-quality, artisanal sandwiches to customers on the go. The press’s portability and ease of use have allowed Alex to offer a premium product that stands out from the competition, solidifying his brand as a beacon of quality in the food truck scene.

A vegan café has seen a significant increase in business since incorporating the NSF sandwich press into its menu. The café’s owner, Jamie, has crafted a variety of plant-based sandwiches that appeal to a diverse clientele. The press’s ability to toast bread without the need for additional fats or oils has been crucial in creating vegan-friendly options that are just as satisfying as their meat-containing counterparts.

In a school cafeteria, the sandwich press has become a favorite among students. Its quick heating and even toasting have reduced the time spent in line, allowing students to grab a hot, delicious sandwich before heading to class. The cafeteria staff has noticed a decrease in complaints about cold or overcooked sandwiches, and the press’s consistent performance has been a hit with both students and staff alike.

A gourmet grocery store has turned to the NSF sandwich press to offer a unique in-store experience. Shoppers can witness the creation of their custom sandwiches, freshly toasted to order, as they browse the aisles. This interactive element has added an educational aspect to the shopping experience, encouraging customers to explore new flavors and ingredients.

A health-conscious café has found a perfect match in the NSF sandwich press for its low-carb, high-protein menu. The press’s ability to toast gluten-free breads without burning has been instrumental in the café’s ability to cater to a wide range of dietary needs. The café’s popularity has soared, with health-conscious consumers lining up for their nutrient-rich, toasted sandwiches.

In a busy hospital kitchen, the sandwich press has become a savior for meal service staff. The ability to quickly prepare warm, comforting sandwiches for patients has helped improve morale and patient satisfaction. The press’s ease of cleaning and its ability to maintain consistent heat have made it an essential tool in a fast-paced environment where every minute counts.

Each of these case studies showcases the versatility and reliability of the NSF sandwich press in a variety of settings. From cafes and corporate offices to sports clubs and gourmet grocery stores, the press has proven to be a valuable asset in creating high-quality, quick-to-prepare sandwiches that cater to diverse tastes and needs. Its NSF approval stands as a guarantee of quality and safety, making it an investment that pays off in both customer satisfaction and operational efficiency.

Investing in an NSF-approved commercial sandwich press is a strategic move that offers a multitude of advantages. Here’s a breakdown of the cost-benefit analysis that underscores why this choice is not just about the initial price tag, but a smart long-term investment.

The upfront cost of an NSF-approved sandwich press may seem steep, especially when compared to lesser-quality or non-certified models. However, this initial expense is often offset by the durability and longevity of the appliance. These presses are built to withstand heavy commercial use, which means they are less likely to break down and require frequent repairs or replacements. The savings over time on maintenance and the replacement of cheaper, less reliable equipment can add up significantly.

Energy efficiency is another critical factor in the cost-benefit equation. NSF-approved commercial sandwich presses are designed with energy conservation in mind, leading to lower electricity bills. This feature is not only environmentally friendly but also contributes to your bottom line by reducing operational costs.

In the world of foodservice, safety is paramount. NSF certification ensures that the sandwich press meets stringent health and safety standards. This peace of mind is invaluable, as it minimizes the risk of recalls, fines, or legal actions that could result from using non-compliant equipment. The cost of avoiding these potential liabilities far outweighs the cost of the press itself.

Maintaining a high standard of food quality is essential for customer satisfaction and repeat business. An NSF-approved sandwich press guarantees consistent cooking temperatures and even pressure distribution, resulting in a perfectly toasted sandwich every time. The value of a satisfied customer base cannot be overstated, as it directly impacts your restaurant’s reputation and revenue.

The lifespan of a commercial appliance is a significant consideration. NSF-certified sandwich presses are built to last, which means you won’t need to invest in new equipment as frequently. This longevity translates into savings on the purchase price of new appliances over time.

Another aspect of the cost-benefit analysis is the potential for increased sales. A high-quality sandwich press can enhance your menu offerings and attract customers who are looking for that perfect toasted sandwich. The increased foot traffic and sales volume can lead to a substantial return on investment, especially in high-traffic areas like food courts, stadiums, or airports.

The reputation of your business is on the line every time you serve a sandwich. An NSF-approved sandwich press not only ensures food safety but also enhances the perceived quality of your products. This perception can lead to higher prices for your sandwiches, as customers are willing to pay more for a product they trust.

From a customer service standpoint, having a reliable and efficient sandwich press can reduce wait times. Happy customers who receive their food quickly are more likely to leave positive reviews and return to your establishment. The indirect benefits of improved customer satisfaction and loyalty are hard to quantify but are substantial in the long run.

Lastly, consider the versatility of an NSF-approved sandwich press. These appliances are not just for sandwiches; they can be used for a variety of food items, from burgers to paninis to grilled cheese. The ability to offer a diverse menu can attract a wider audience and potentially increase sales across your entire foodservice operation.

In conclusion, while the initial cost of an NSF-approved commercial sandwich press may seem high, the long-term savings, efficiency gains, and benefits to your business’s reputation and customer satisfaction make it a sound investment. The cost-benefit analysis clearly shows that the peace of mind, operational savings, and potential for increased sales justify the initial expense, solidifying the sandwich press as a worthwhile investment for any foodservice establishment.

In the bustling world of commercial kitchens, where efficiency and hygiene are paramount, maintaining the longevity of your NSF-approved sandwich press is crucial. Here’s how to keep it in top shape:

The heat elements of a sandwich press are its beating heart. Regularly inspect these components for any signs of wear or damage. Cracks, discoloration, or loose connections could indicate the need for repair or replacement. Cleaning the heat elements thoroughly after each use ensures they distribute heat evenly, preserving the integrity of your sandwiches.

The hinges and pressure mechanisms are often the unsung heroes of a sandwich press. These parts bear the brunt of the sandwich-making process and can succumb to wear over time. Keep them lubricated with food-grade grease to ensure smooth operation. Periodic checks for alignment can prevent uneven pressure and maintain the quality of your output.

The exterior of your NSF sandwich press should also be maintained. Wipe down the surfaces with a damp cloth after each use to prevent food residue from becoming a stubborn stain. If the surface is non-stick, use gentle cleaners to avoid damaging the coating. For stainless steel or other metals, opt for a cleaner designed to prevent corrosion.

The non-stick coating inside the press is a game-changer for convenience and hygiene. However, it requires special care. Avoid using abrasive cleaners or steel wool, as they can scratch the surface. Opt for a non-abrasive cleaner and a soft cloth. If the coating starts to degrade, it’s best to replace the press rather than risk food sticking or bacteria growth.

The electrical components of your sandwich press are not only critical for safety but also for the longevity of the appliance. Regularly check the power cord for any signs of fraying or damage. If you notice anything amiss, disconnect the press immediately and have it repaired or replaced. Never use a sandwich press with a damaged power cord, as it poses a significant safety hazard.

Sanitary conditions are a must in commercial kitchens, and your sandwich press is no exception. After each use, ensure that the press is completely dry before storing it. Moisture can lead to rust and corrosion, which can compromise the press’s performance and lifespan. Additionally, store the press in a cool, dry place away from direct sunlight to prevent overheating and potential damage.

For those who use their sandwich press extensively, it’s wise to invest in a second one for backup. In the event that one press needs maintenance or repair, you won’t be left without the ability to serve your customers. This redundancy also allows for more frequent cleaning and maintenance, keeping both presses in optimal condition.

If you find that your NSF sandwich press is not performing as well as it used to, it might be time to replace it. Over time, even the highest-quality sandwich presses can wear out. Look for signs like uneven heating, inconsistent pressure, or difficulty in opening and closing. These are clear indicators that it’s time for a new unit.

In conclusion, the key to maintaining your NSF sandwich press lies in regular cleaning, proper lubrication, and prompt attention to any signs of wear or damage. By following these steps, you can ensure that your sandwich press remains a reliable and efficient workhorse in your kitchen for years to come.

In the ever-evolving world of commercial kitchen appliances, the sandwich press has emerged as a staple in both quick-service restaurants and high-end eateries. As we look ahead to the next decade, several trends and technological advancements are poised to redefine the future of commercial sandwich presses. From smart features to sustainable materials, here’s what you can expect in the coming years.

The integration of smart technology is likely to become a norm in commercial sandwich presses. Imagine a unit that can monitor its own performance, predict maintenance needs, and even adjust its heat settings based on the type of bread being used. This level of intelligence would not only improve efficiency but also ensure consistent quality in every sandwich prepared.

With the growing emphasis on sustainability, the next generation of sandwich presses may be crafted from eco-friendly materials. Recycled metals, sustainable woods, and biodegradable plastics could become the new standard, aligning with the broader shift towards greener operations in the foodservice industry.

Energy efficiency is another key area where we can anticipate significant advancements. As businesses strive to reduce their carbon footprint, sandwich presses that consume less energy will become more attractive. Innovations like heat recovery systems and improved insulation could lead to substantial savings on energy bills while keeping the presses running smoothly.

Customization will play a crucial role in the future of sandwich presses. The ability to cater to diverse dietary preferences and restrictions will be a hallmark of the next decade. From gluten-free to vegan options, the presses will likely feature adjustable settings that allow for precise control over the cooking process, ensuring that every sandwich meets the specific requirements of various customers.

The convenience of touchless operation is also expected to gain traction. In an era where hygiene is paramount, sandwich presses that can be activated and operated without physical contact will be a hit. This not only minimizes the risk of cross-contamination but also enhances the overall cleanliness of the kitchen.

In terms of design, compactness will be a key feature. As kitchen space becomes more premium, sandwich presses that are sleek and space-saving will be in high demand. These compact units will be designed to fit seamlessly into various kitchen layouts, from bustling cafes to busy fast-food chains.

Another trend to watch for is the inclusion of advanced safety features. With the potential for high heat and pressure, ensuring the safety of both operators and customers will be a top priority. Features like automatic shut-off mechanisms, temperature control systems, and safety locks will be standard in the next decade’s sandwich presses.

The ability to handle a variety of bread types and thicknesses will also be a hallmark of future commercial sandwich presses. From artisanal loaves to thin buns, these units will be engineered to deliver consistent results across the board, making them versatile tools for any kitchen.

Lastly, the integration of data analytics may become a part of the sandwich press’s future. With the ability to track usage patterns, maintenance schedules, and performance metrics, businesses will gain valuable insights that can inform operational decisions and improve customer satisfaction.

In conclusion, the commercial sandwich press of the next decade will be a testament to innovation, sustainability, and customer-centric design. As the industry continues to evolve, the sandwich press will undoubtedly play a pivotal role in shaping the future of quick-service and full-service kitchens alike.

In embracing the NSF-approved commercial sandwich press, kitchen operators are not just investing in a piece of equipment; they’re making a strategic move towards profitability and efficiency. Here’s why this choice is a game-changer for any kitchen environment.

Consider the rise in demand for fast, high-quality sandwiches. With consumers seeking convenience without compromising on taste, the sandwich press has emerged as a cornerstone of quick-service restaurants, delis, and cafes. By choosing an NSF-approved model, you’re not just meeting a standard; you’re exceeding it, ensuring that your offerings stand out in a crowded market.

The NSF label is more than just a certification; it’s a promise of quality and safety. It means that the sandwich press has been rigorously tested and meets stringent standards for material safety, structural integrity, and performance. This level of assurance can significantly boost customer confidence, as they know they’re getting a product that has been vetted by a trusted third party.

One of the key advantages of an NSF-approved sandwich press is its versatility. These presses are designed to handle a variety of breads and fillings, from classic ham and cheese to gourmet creations with unique ingredients. This adaptability is crucial in a market where trends change rapidly, and customers have diverse preferences.

Efficiency is another critical factor in the kitchen, and the NSF sandwich press is engineered to maximize productivity. With features like adjustable heat settings and quick heat-up times, operators can serve more customers in less time. The consistent cooking results ensure that every sandwich is cooked to perfection, reducing waste and increasing customer satisfaction.

In terms of cost, the initial investment in an NSF-approved sandwich press might be higher than a generic model. However, when you consider the long-term benefits, the cost-effectiveness becomes clear. The durability of these presses means fewer repairs and replacements, saving money over time. Plus, the increased sales and customer loyalty due to the high-quality product can significantly outweigh the initial expense.

The maintenance aspect of an NSF sandwich press is also worth noting. These models are designed with ease of cleaning in mind, which is essential in a commercial kitchen where hygiene is paramount. Regular maintenance not only prolongs the life of the press but also ensures consistent performance, which is key to maintaining a smooth operation.

In the world of commercial sandwich presses, innovation is not just a buzzword; it’s a driving force. Manufacturers are continuously pushing the boundaries with new designs and features that make these presses even more efficient and user-friendly. From non-stick surfaces that simplify cleanup to programmable settings that allow for precise temperature control, the future of sandwich presses is bright.

When it comes to investing in a sandwich press, the NSF label is a beacon of trust. It’s a signal that you’re choosing a product that has been scrutinized and approved by experts in the field. This level of assurance is invaluable, especially in the foodservice industry where safety and quality are non-negotiable.

In a competitive market, the ability to offer a unique, high-quality product can set a business apart. The NSF-approved commercial sandwich press allows operators to do just that. It’s not just about making a sandwich; it’s about providing an experience that keeps customers coming back for more.

In conclusion, the NSF-approved commercial sandwich press is a smart investment for any kitchen looking to enhance its offerings. With its combination of quality, safety, efficiency, and innovation, this piece of equipment is poised to be a staple in commercial kitchens for years to come. By choosing an NSF-approved model, you’re not just buying a sandwich press; you’re buying into a future where your kitchen operations are more profitable and efficient than ever before.