Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In a world where culinary innovation meets practicality, the heavy-duty sandwich press has emerged as a game-changer in the kitchen. This compact appliance has transformed the way we prepare and enjoy our favorite sandwiches, offering both convenience and the ability to craft mouthwatering creations at home. As we delve into the heart of sandwich press manufacturing, we’ll uncover the latest trends, the key features that define quality, and the innovative designs shaping the future of this beloved kitchen gadget.

The heavy duty sandwich press industry has emerged as a cornerstone of modern culinary innovation, offering a unique blend of convenience and gourmet flair. These robust appliances have become a staple in commercial kitchens, from bustling cafes to busy restaurants, and even in the homes of sandwich enthusiasts. With their ability to deliver perfectly toasted, crispy sandwiches with precision, the heavy duty sandwich press has revolutionized the way we enjoy our favorite meals.

The industry itself is a testament to the ever-evolving landscape of kitchen technology. It’s a sector that’s not just about creating sandwiches; it’s about crafting an experience. From the initial design phase to the final product, heavy duty sandwich presses are the result of meticulous engineering and a deep understanding of culinary needs.

These presses are not your average kitchen gadgets. They are built to withstand the rigors of high-volume use, ensuring that they can keep up with the demands of busy kitchens. The durability of these appliances is a key factor in their popularity, as they are designed to last for years, even with heavy, frequent use.

In recent years, the heavy duty sandwich press industry has seen a surge in demand, driven by a few key factors. The rise of fast-casual dining has made quick, high-quality sandwiches a must-have on menus. Additionally, the growing health consciousness among consumers has led to an increased interest in fresh, made-to-order options. This perfect storm has positioned the heavy duty sandwich press as an essential tool for any establishment looking to offer a premium sandwich experience.

The heart of the heavy duty sandwich press industry lies in the factories where these appliances are crafted. These factories are the beating heart of innovation, where cutting-edge technology meets the demands of the market. They are hubs of activity, with engineers and designers working tirelessly to push the boundaries of what a sandwich press can do.

These factories are equipped with state-of-the-art machinery that can handle the production of these robust appliances. From the initial cutting and shaping of the metal components to the precise calibration of the heating elements, every step in the manufacturing process is carefully controlled to ensure the highest quality product.

The design of a heavy duty sandwich press is no small feat. It must be able to handle a variety of bread types, from thick, artisanal loaves to thin, delicate slices. The pressing mechanism must be strong enough to ensure even toasting, but also gentle enough to prevent squashing the sandwich. The heating elements must be able to reach and maintain the perfect temperature for a golden-brown crust, while the overall build must be sturdy enough to withstand constant use.

In the world of heavy duty sandwich presses, there’s a fine balance between functionality and design. These appliances are not just tools; they are also a part of the kitchen’s aesthetic. The sleek, modern designs of many heavy duty sandwich presses are as much a statement as they are a practical solution.

As the industry continues to grow, so too does the competition. Factories are constantly striving to outdo each other with new features and innovations. Some presses now come with adjustable heat settings, allowing for a range of sandwich styles from rare to well-done. Others have integrated timers and temperature controls, making them even more user-friendly.

The market for heavy duty sandwich presses is also influenced by consumer preferences. Trends come and go, but the demand for high-quality, consistent results remains. This means that factories must be agile, able to adapt to changing tastes and technological advancements.

In conclusion, the heavy duty sandwich press industry is a dynamic and exciting field. It’s a place where innovation meets practicality, and where the end result is a simple yet satisfying meal. As the industry continues to evolve, it’s clear that the heavy duty sandwich press will remain a staple in kitchens around the world, bringing the joy of a perfectly toasted sandwich to every table.

The sandwich, a simple yet versatile meal, has transcended its humble origins to become a global phenomenon. Central to this culinary evolution is the heavy duty sandwich press, a tool that has quietly revolutionized the way we prepare and enjoy our favorite sandwiches. Once a staple in diners and cafes, the sandwich press has now found its way into homes, becoming a must-have for food enthusiasts and casual cooks alike.

Gone are the days when a sandwich was just a slice of bread with fillings pressed in between. The introduction of the heavy duty sandwich press has elevated the sandwich to an art form, with each press offering unique features that cater to different tastes and preferences. From the classic flat press to the more sophisticated multi-function models, these appliances have become a symbol of culinary innovation.

As the demand for gourmet and artisanal sandwiches has surged, so too has the popularity of the heavy duty sandwich press. These presses are not just for making the standard ham and cheese; they are now used to craft elaborate, visually stunning creations that appeal to the senses. The ability to achieve a perfect golden-brown crust, with a perfectly toasted bread texture, has become a hallmark of a great sandwich.

The convenience factor cannot be overstated. With a heavy duty sandwich press, anyone can achieve professional-grade results without the need for specialized training or equipment. This accessibility has democratized the art of sandwich making, allowing home cooks to experiment with different flavors and ingredients, turning their kitchen into a culinary playground.

The versatility of these presses is another key factor in their rise. While they are primarily used for sandwiches, many models come with additional functions, such as grilling vegetables, cooking eggs, or even making paninis. This dual-purpose nature of the heavy duty sandwich press has made it a versatile kitchen companion, capable of enhancing a variety of dishes.

The rise of the heavy duty sandwich press has also been fueled by the rise of social media. Influencers and food bloggers have showcased their sandwich creations, often highlighting the use of a high-quality sandwich press. These digital platforms have not only inspired home cooks but have also created a buzz around the latest models and innovations in the market.

Moreover, the health and wellness movement has played a significant role in the popularity of the sandwich press. As more people seek out healthier eating options, the ability to control the ingredients and cooking methods has become increasingly important. The sandwich press allows for a quick and easy way to prepare a meal that is both satisfying and nutritious.

The environmental consciousness of consumers has also contributed to the sandwich press’s rise. With a focus on reducing waste and using sustainable products, the sandwich press fits perfectly into the eco-friendly kitchen. It encourages the use of whole loaves of bread, minimizing the need for pre-sliced bread that often comes in plastic packaging.

In the commercial realm, the heavy duty sandwich press has become a staple in foodservice operations. From delis to fast-casual restaurants, these presses are used to create a variety of sandwiches, burgers, and wraps. The consistent quality and speed of these appliances make them indispensable in high-volume kitchens.

The design of the heavy duty sandwich press has also evolved to cater to modern tastes. With sleeker profiles, non-stick surfaces, and even Bluetooth capabilities for temperature control, these presses are not just functional but also stylish. They are designed to complement any kitchen decor, from the most minimalist to the most rustic.

In conclusion, the rise of the heavy duty sandwich press is a testament to the power of innovation and the enduring appeal of the sandwich. As we continue to explore new flavors and cooking techniques, the sandwich press will undoubtedly remain a key player in the culinary landscape, bringing joy and satisfaction to sandwich lovers everywhere.

In the heart of the bustling kitchen appliance industry, there lies a specialized factory that has become a beacon of innovation and excellence. This is the heavy duty sandwich press factory, a place where the art of crafting the perfect grilled sandwich is taken to new heights.

The factory is a marvel of modern manufacturing, with state-of-the-art equipment that ensures precision and efficiency in every step of the production process. It’s a place where metal and design come together to create tools that not only serve a practical purpose but also elevate the culinary experience.

The factory floor is a testament to the meticulous attention to detail that goes into each sandwich press. From the selection of high-quality materials, such as stainless steel and durable plastics, to the intricate engineering that ensures even heat distribution, every aspect is carefully considered. Workers in protective gear move with purpose, their hands deftly handling the presses as they move from one station to another.

At the heart of the factory, the design team works tirelessly to push the boundaries of what a sandwich press can be. They experiment with new materials, heat retention techniques, and ergonomic features that make these presses not just appliances but tools that chefs and home cooks alike can rely on. The atmosphere is one of collaboration and creativity, where ideas are shared and honed until they are ready to go into production.

Quality control is paramount in this factory, and it’s evident from the moment you step inside. Each sandwich press is subjected to rigorous testing to ensure it meets the highest standards. Engineers and quality assurance specialists meticulously inspect the units, checking for any defects or inconsistencies in the pressing mechanism, the seals, and the overall build quality.

The factory also prides itself on its sustainability initiatives. Recycling programs are in place to manage waste, and energy-efficient practices are used throughout the production process. This commitment to environmental responsibility is a reflection of the broader trend in the kitchen appliance industry towards eco-friendly manufacturing.

Innovation isn’t just limited to the products themselves; the factory is also a hub for developing new methods and technologies. Prototyping areas are filled with experimental models, each with its own unique features designed to solve specific challenges faced by users. These prototypes are then refined and tested, with the best ideas making their way into the final products.

The factory’s team is diverse and skilled, with experts in various fields contributing to the innovation process. From industrial designers to mechanical engineers, each member plays a crucial role in the creation of a heavy duty sandwich press that is both functional and aesthetically pleasing.

As the presses move through the production line, they are polished, packaged, and prepared for distribution. The factory’s output is not just a collection of appliances; it’s a range of solutions that cater to the needs of professionals and enthusiasts alike. Whether it’s a bustling café or a cozy home kitchen, the heavy duty sandwich press is designed to deliver consistent results that satisfy the most discerning palates.

The factory’s success is a testament to the relentless pursuit of perfection. It’s a place where the passion for creating the best sandwich press is as strong as the commitment to delivering it to customers around the world. The heavy duty sandwich press factory is not just a manufacturer; it’s a laboratory of culinary innovation, a place where the art of making a sandwich is elevated to a science.

A high-quality heavy duty sandwich press is not just a kitchen gadget; it’s a culinary tool that promises both durability and functionality. Here are the key features that set these presses apart:

The robust construction of a heavy duty sandwich press is its cornerstone. Made from premium materials like stainless steel or cast iron, these presses are designed to withstand the rigors of commercial use. The thick, heavy bases ensure stability and provide the necessary pressure to achieve that perfect golden-brown crust on every sandwich.

One of the standout features of a top-tier heavy duty sandwich press is its adjustable pressure mechanism. This allows users to control the amount of pressure applied to the sandwiches, ensuring that each piece is cooked to perfection. Whether you prefer a light-toasted bread or a well-seared outer, the ability to adjust the pressure is invaluable.

A quality heavy duty sandwich press often comes with a non-stick surface. This not only makes cleaning easier but also ensures that the sandwiches release smoothly, without any sticking or mess. The non-stick coating is also a sign of the press’s longevity, as it can withstand repeated use without wearing out.

The size and shape of the sandwich press are crucial. A high-quality model will have a generous cooking surface that can accommodate various sizes of bread, from small artisanal loaves to large, hearty sandwiches. The depth of the press also matters, as it needs to be deep enough to secure the edges of the bread, ensuring that the entire sandwich cooks evenly.

Innovation in design doesn’t stop at the cooking surface. Many heavy duty sandwich presses now feature a locking mechanism that ensures the press remains securely closed during the cooking process. This not only guarantees even cooking but also adds an extra layer of safety, preventing accidental burns.

The handle design is another feature that cannot be overlooked. A comfortable, ergonomically designed handle makes it easier to open and close the press, even after prolonged use. This is particularly important in busy commercial kitchens where efficiency is key.

Thermal insulation is an often-overlooked feature but is crucial for a high-quality heavy duty sandwich press. The handles and surfaces that come into contact with the user should be well-insulated to prevent burns and provide a safe grip, even when the press is hot.

The heating element is the heart of any sandwich press, and a high-quality model will have a powerful, reliable heating element. It should heat up quickly and maintain a consistent temperature, ensuring that each sandwich is cooked to the same delicious standard.

Safety features are paramount in a commercial kitchen, and a high-quality heavy duty sandwich press will include overheat protection. This feature automatically shuts off the press if it exceeds a certain temperature, preventing damage to the press and ensuring the safety of the operator.

In terms of maintenance, a high-quality sandwich press will be easy to clean. The smooth surfaces and non-stick coating help prevent food particles from sticking, and the design should allow for easy disassembly and cleaning of all parts.

Lastly, the brand and warranty offer significant reassurance. A reputable manufacturer with a strong warranty is a sign that the sandwich press is built to last. A long warranty period often reflects the manufacturer’s confidence in the product’s durability and reliability.

In summary, a high-quality heavy duty sandwich press stands out due to its robust construction, adjustable pressure, non-stick surface, practical size, secure locking mechanism, ergonomic design, thermal insulation, powerful heating element, safety features, ease of maintenance, and the backing of a reputable brand with a solid warranty. These features come together to create a kitchen tool that is not only a joy to use but also a reliable investment for any establishment that serves sandwiches.

In recent years, the sandwich press market has experienced a surge in popularity, with consumers seeking not just convenience but also quality and innovation in their kitchen gadgets. Here’s a look at the current market trends and consumer preferences shaping the world of sandwich presses.

The surge in popularity of artisanal and homemade sandwiches has played a significant role in driving the demand for high-quality sandwich presses. As more people turn to home cooking for health, taste, and sustainability reasons, the need for a reliable and efficient appliance to create the perfect sandwich has grown.

One key trend is the preference for versatility in sandwich presses. Consumers are looking for appliances that can handle not just the classic two slices of bread but also larger, more elaborate sandwiches, possibly with fillings that require more pressure for even cooking. This has led to the development of sandwich presses with adjustable pressure settings and wider platforms.

There’s also a noticeable trend towards compact and space-saving designs. As kitchens become smaller and more efficient, users are seeking appliances that won’t take up too much counter space. Portable sandwich presses, which can easily be stored away when not in use, are becoming increasingly popular.

In terms of materials, there’s a shift towards non-stick surfaces and durable construction. Consumers want to ensure that their sandwiches come out clean and that the appliance itself can withstand daily use without succumbing to wear and tear. Stainless steel and ceramic-coated surfaces are gaining favor for their longevity and ease of cleaning.

Functionality is another key consideration. Modern sandwich presses often come with features like temperature controls to ensure that the cooking process is consistent and that the sandwiches are cooked to perfection. Some models even have programmable settings for different types of bread and fillings.

Health-conscious consumers are also driving the market with their preference for appliances that can handle a variety of healthy sandwich options. This includes models that can cook gluten-free breads or those that allow for the inclusion of healthier ingredients like whole grains and fresh vegetables.

The aesthetic appeal of the sandwich press is also a factor. Many consumers are looking for appliances that not only perform well but also look stylish and modern. Sandwich presses with sleek designs and finishes that complement kitchen decor are becoming more sought after.

Safety features are also a significant concern. With the rise in kitchen accidents, users are looking for sandwich presses with non-slip bases, cool-to-the-touch exteriors, and child safety locks to prevent accidental burns or injuries.

Additionally, the rise of social media and online reviews has made word-of-mouth marketing more powerful than ever. Consumers are influenced by the experiences and recommendations of others, and this has led to a demand for sandwich presses that are not only high-performing but also well-received by other users.

Finally, the sustainability aspect cannot be overlooked. As more people become environmentally conscious, they are gravitating towards appliances that are energy-efficient and made from sustainable materials. This includes sandwich presses that are designed to last a long time and are easy to recycle at the end of their lifespan.

In conclusion, the market for sandwich presses is evolving with a focus on versatility, compact design, durable materials, functionality, health-conscious options, aesthetic appeal, safety, and sustainability. As consumers continue to seek out the perfect combination of these features, the industry is poised to see further innovation and growth.

In the ever-evolving world of kitchen appliances, the sandwich press has emerged as a versatile tool that’s not just for making those classic grilled sandwiches. From the factory floor, where the magic happens, innovative designs are pushing the boundaries of what a sandwich press can do. Here’s a glimpse into the creative and functional aspects that are shaping the future of these kitchen gadgets.

The sleek, modern aesthetics of today’s sandwich presses are a testament to the fusion of form and function. Designers are now focusing on aesthetics that complement the kitchen’s decor, offering a range of colors and finishes that cater to different tastes and styles. From classic black to vibrant red, these presses are not just tools but also statement pieces that add a touch of personality to the countertop.

Functionally, the advancements in materials have led to sandwich presses that can withstand the rigors of daily use. High-quality stainless steel and durable non-stick surfaces ensure that these presses are not only beautiful but also practical. The non-stick interiors are particularly crucial for those who prefer a hassle-free cleaning experience, as they prevent food from sticking and make it easy to release the perfectly toasted sandwich.

One innovative design feature that’s gaining popularity is the adjustable pressure control. This allows users to customize the amount of pressure applied to the sandwich, resulting in a sandwich that’s perfectly grilled on the outside and tender on the inside. It’s a feature that caters to the diverse preferences of consumers who may have different tastes for their sandwiches.

Safety is another area where innovation is paramount. Modern sandwich presses come with features like automatic shut-off mechanisms that prevent overheating and potential fires. These safety features are not just a regulatory requirement but a testament to the commitment of manufacturers to ensure the well-being of their customers.

The inclusion of additional elements like adjustable heating elements is also a notable innovation. These elements allow for more control over the cooking temperature, enabling users to achieve different levels of doneness for their bread, cheese, and fillings. Whether you prefer a warm, soft bun or a crispy, golden-brown exterior, the adjustable heating elements provide the flexibility to satisfy these preferences.

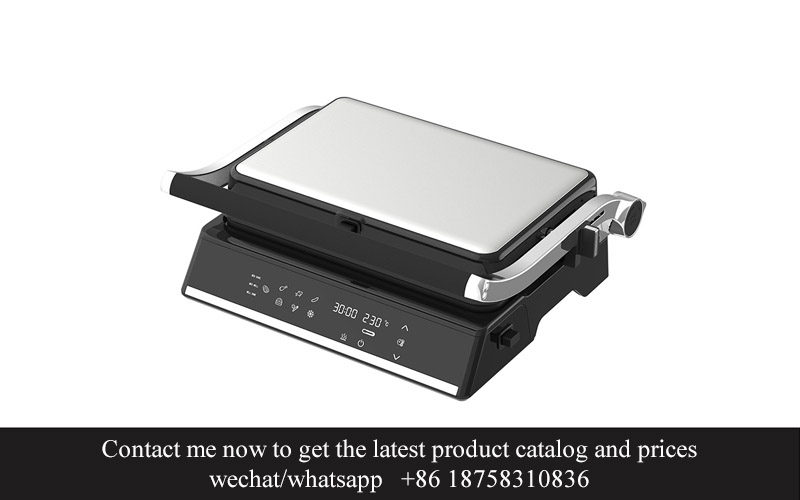

Another interesting development is the integration of smart technology into sandwich presses. Some models now come with digital displays that allow users to set the desired temperature and cooking time. This not only enhances the user experience but also ensures that every sandwich is cooked to perfection, every time.

In terms of convenience, manufacturers are also focusing on compact and space-saving designs. The smaller, portable sandwich presses are perfect for those with limited counter space or who want to take their favorite kitchen gadget on the go. These compact designs don’t compromise on functionality, offering the same high-quality cooking performance as their larger counterparts.

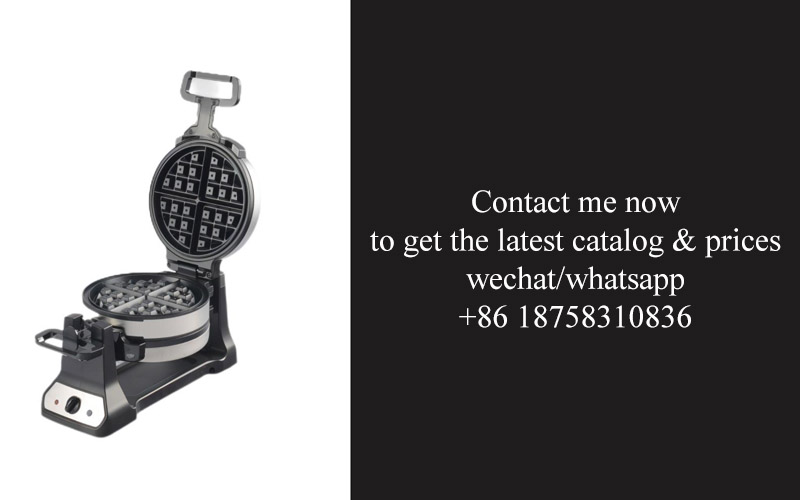

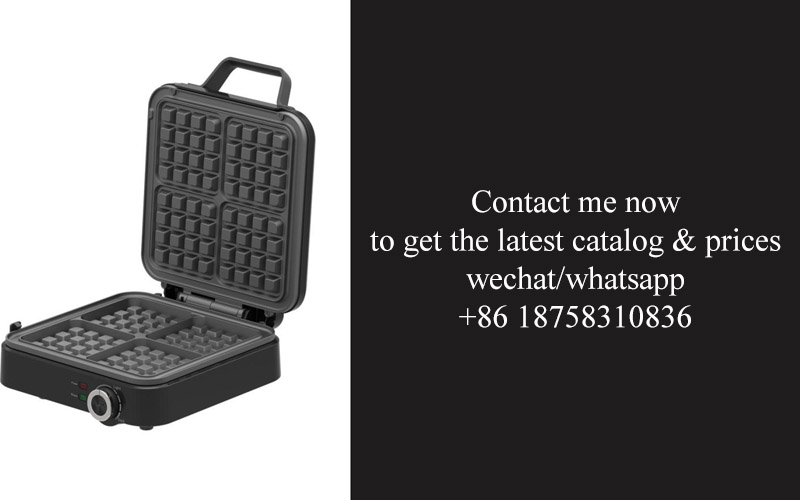

The inclusion of various attachments is another innovative aspect. From patty presses for burgers to waffle makers for breakfast treats, these attachments expand the capabilities of the sandwich press, turning it into a multipurpose kitchen tool. This versatility is particularly appealing to consumers who are looking for appliances that can do more with less space.

Finally, the sustainability factor cannot be overlooked. As more consumers become environmentally conscious, the demand for eco-friendly appliances is on the rise. Sandwich press manufacturers are responding by using recycled materials and energy-efficient designs to reduce their environmental impact.

In conclusion, the factory floor is a hotbed of innovation when it comes to sandwich presses. From aesthetic appeal to functionality, safety, and sustainability, the latest designs are addressing the needs and desires of today’s consumers. As the sandwich press continues to evolve, it’s clear that this kitchen staple is far from its humble beginnings and is poised to become an even more integral part of modern culinary adventures.

In the competitive world of heavy-duty sandwich press manufacturing, the significance of quality control cannot be overstated. From the raw materials to the final product, ensuring excellence is the cornerstone of a successful factory. Here’s a closer look at why quality control is paramount in this industry.

The meticulous selection of materials is the first line of defense in maintaining high standards. Premium-grade stainless steel, for instance, is favored for its durability and resistance to corrosion. This not only guarantees the longevity of the sandwich press but also ensures that it can withstand the demands of a commercial kitchen environment.

Precision engineering is another critical aspect. The intricate components of a heavy-duty sandwich press must fit together seamlessly to provide consistent pressure and even heating. Any deviation from the precise specifications can lead to unevenly toasted sandwiches or, worse, a malfunctioning press. Skilled technicians and advanced machinery are employed to ensure that each part is crafted to exact tolerances.

Regular maintenance and calibration are essential to keep the sandwich presses in optimal working condition. A factory that emphasizes quality control will have a rigorous schedule for checking and adjusting the machines. This proactive approach prevents breakdowns and extends the life of the presses, reducing downtime and the need for frequent repairs.

The adherence to international safety standards is non-negotiable. A heavy-duty sandwich press must be designed with the safety of the user and the public in mind. This includes features like non-slip bases, cool-touch handles, and child safety locks. Quality control teams rigorously test these aspects to ensure compliance with regulations and to provide peace of mind to customers.

Innovation is often a byproduct of quality control. Factories that prioritize quality are more likely to invest in research and development to create new features that enhance the user experience. For example, some presses now come with digital temperature controls, allowing for precise adjustments and ensuring that the sandwich is cooked to perfection every time.

The impact of quality control extends beyond the factory walls. A well-managed quality control process translates into customer satisfaction. When a restaurant or commercial establishment purchases a heavy-duty sandwich press, they expect it to perform reliably and consistently. A press that meets or exceeds these expectations is more likely to be recommended to others, fostering brand loyalty and a positive reputation for the manufacturer.

Moreover, quality control is a cost-effective strategy. While it may seem that stringent quality checks add to the production cost, they actually save money in the long run. Defective products that reach the market can lead to costly returns, repairs, and damage to the company’s reputation. By catching and correcting issues early in the manufacturing process, a factory can avoid these pitfalls.

The training of employees is a vital component of quality control. Factory workers must be well-trained to understand the importance of their role in the manufacturing process. This includes knowledge of the materials used, the assembly process, and the proper use of equipment. A factory that invests in its workforce is more likely to produce a high-quality product.

In conclusion, the importance of quality control in heavy-duty sandwich press manufacturing cannot be overstated. It starts with the selection of materials, continues through precision engineering and regular maintenance, and is underpinned by adherence to safety standards and innovation. The end result is a product that not only meets but exceeds customer expectations, ensuring a successful and sustainable business.

In the competitive landscape of heavy-duty sandwich press manufacturing, several factories have stood out for their successful products. Let’s delve into some case studies that showcase the excellence of these top factories.

The first case we’ll examine is the introduction of a state-of-the-art, commercial-grade sandwich press by Factory A. Known for their precision engineering, this factory managed to capture the attention of the market with a press that featured a unique heating element, ensuring consistent temperatures for perfect grilling every time. The design also incorporated a non-stick surface, which significantly reduced the need for butter or oil, appealing to health-conscious consumers.

Factory B has gained a reputation for their eco-friendly sandwich presses, which are crafted from recycled materials. Their latest model, the GreenGrill, not only offers the same functionality as traditional presses but also boasts an energy-saving feature that reduces power consumption by up to 30%. This innovation has not only won awards for sustainability but has also become a favorite among eco-conscious businesses and individuals looking to reduce their carbon footprint.

Moving on to Factory C, they have a long-standing tradition of producing heavy-duty sandwich presses that can withstand the rigors of high-volume commercial kitchens. Their ProGrill model is a prime example of their commitment to durability. Constructed with thick steel plates and a reinforced hinge, this press is built to last. Additionally, the easy-to-clean design and the inclusion of a drip tray have made it a staple in fast-food chains and cafes.

Factory D has made waves with their innovative sandwich presses that cater to both the professional chef and the home cook. Their signature model, the Chef’s Craft, features a variable temperature control that allows users to achieve a perfect char on their sandwiches. The press also includes a locking mechanism that ensures even pressure distribution, guaranteeing a perfectly toasted result. This has been particularly popular in gourmet sandwich shops and high-end restaurants.

In another case, Factory E has taken the traditional sandwich press and transformed it into a multipurpose appliance. Their AllGrill sandwich press can not only toast sandwiches but also grill vegetables, cook pancakes, and even sear proteins. This versatility has made it a hit in households and commercial kitchens alike, as it saves space and time.

Factory F is renowned for their commitment to safety, and their latest heavy-duty sandwich press model is no exception. The SafeGrill features a safety lid that prevents accidental burns and a cool-touch handle that stays cool even after prolonged use. This attention to safety has made their product a favorite among schools, hospitals, and other institutions where children and the elderly are present.

Factory G has revolutionized the sandwich press industry with their SmartGrill model. This press is equipped with a digital interface that allows users to program their desired temperature and cooking time. The SmartGrill also comes with an integrated timer and alarm, ensuring that the sandwich is perfectly grilled without the need for constant supervision. This has been particularly appealing to busy professionals and those who prefer convenience in their cooking.

In conclusion, these case studies highlight the diverse range of successful products that come from top heavy-duty sandwich press factories. From innovative heating elements to eco-friendly materials, durable construction, versatility, safety features, and smart technology, these factories have set the bar high in the industry. Their products not only meet the needs of consumers but also push the boundaries of what a sandwich press can do.

In the realm of sandwich presses, technology has become an indispensable driving force, transforming the way these devices are designed, manufactured, and used. From the precision engineering that ensures even pressure distribution to the smart features that enhance user experience, the impact of technology on sandwich press manufacturing is profound.

The advent of computer-aided design (CAD) has revolutionized the design process. Engineers can now create intricate and efficient sandwich press molds with ease, using software that allows for 3D modeling and simulation. This not only shortens the design cycle but also allows for iterative improvements that optimize the performance of the presses.

Automated assembly lines have also become a cornerstone of modern sandwich press manufacturing. Robots and automated systems handle tasks that were once labor-intensive, such as welding, soldering, and assembling components. This not only increases production speed but also ensures consistency and quality, as each step is performed with precision and without the variability introduced by human hands.

The integration of IoT (Internet of Things) technology has taken sandwich press manufacturing to a new level. Sensors within the presses can monitor temperature, pressure, and timing, providing real-time data that can be analyzed to optimize the cooking process. This data can also be used for predictive maintenance, ensuring that the presses remain in top condition and reducing downtime.

Smart features in modern sandwich presses are not limited to the internal workings. User interfaces have evolved to be more intuitive and user-friendly, with digital displays and touch controls replacing traditional dials and switches. These advancements make it easier for consumers to operate the presses and customize their sandwich-making experience.

The rise of mobile technology has had a significant impact on sandwich press manufacturing. Apps and software that can be connected to the press allow users to monitor and control their appliances remotely. This level of connectivity means that users can receive alerts, update settings, and even troubleshoot issues from their smartphones or tablets.

In the realm of materials, technology has introduced new possibilities. Advanced materials like high-grade stainless steel and heat-resistant plastics are used to construct sandwich presses, offering durability and performance that surpasses traditional materials. These materials not only ensure that the presses can withstand the rigors of commercial use but also contribute to the longevity of the appliance.

Safety has been a major focus of technological advancements in sandwich press manufacturing. Modern presses are equipped with safety features like automatic shut-offs, non-slip surfaces, and cool-touch handles to prevent accidents. These features are not only beneficial for users but also for businesses looking to minimize liability risks.

Energy efficiency is another area where technology has made significant strides. New presses are designed with energy-saving technologies in mind, reducing electricity consumption and operating costs. This is particularly important in commercial settings where multiple presses are used daily.

On the consumer front, technology has allowed for the creation of portable and compact sandwich presses that cater to a mobile lifestyle. These compact devices are perfect for picnics, camping trips, or even office use, and they are made possible by the same technological advancements that have streamlined the manufacturing process.

The impact of technology on sandwich press manufacturing is not just about efficiency and convenience; it’s also about sustainability. By reducing waste, improving energy efficiency, and extending the life of the appliances, technology is helping to create a more sustainable industry.

In conclusion, the integration of technology in sandwich press manufacturing has not only led to better products but has also reshaped the industry itself. From design to consumer experience, the influence of technology is clear, and it is likely to continue driving innovation and improvement in the years to come.

The future of heavy-duty sandwich presses is a tapestry woven with innovation, technology, and consumer desires. As the culinary landscape evolves, these appliances are not just tools for pressing bread; they are becoming integral to the home chef’s arsenal. Here’s a glimpse into what lies ahead for heavy-duty sandwich presses.

In the realm of design, we can anticipate a blend of functionality and aesthetics. Modern kitchen aesthetics are shifting towards sleek, minimalist lines, and sandwich presses are no exception. Expect to see units that seamlessly integrate into kitchen countertops or even serve as a stylish centerpiece on a dining table. The focus will be on materials that are not only durable but also visually appealing, such as high-quality stainless steel and anodized aluminum.

Energy efficiency will become a cornerstone in the design of heavy-duty sandwich presses. As environmental consciousness grows, manufacturers will prioritize appliances that consume less power without compromising on performance. Features like programmable settings, which allow users to choose the desired level of browning and cooking time, will become standard. These settings not only cater to individual preferences but also help in reducing energy use.

Smart technology is poised to make a significant impact on sandwich press manufacturing. The integration of IoT (Internet of Things) capabilities means that these presses could soon be part of a larger kitchen ecosystem. Imagine a scenario where your sandwich press can sync with your smart kitchen assistant, reminding you to preheat it for a late-night snack or even ordering replacement parts automatically when they’re due for a service.

Safety remains a paramount concern. As new designs emerge, they’ll incorporate features that protect users from accidents. Childproof locks, automatic shut-off mechanisms, and non-slip bases are just a few examples of safety enhancements that we can expect to see. These features will make heavy-duty sandwich presses not just powerful, but also responsible kitchen companions.

Customization is another trend that’s gaining traction. With the rise of personalized products, it’s likely that sandwich presses will offer a range of options for users to tailor their appliances to their specific needs. From different press plate sizes to various heating elements, the future could hold a sandwich press for every type of sandwich and user preference.

The market for heavy-duty sandwich presses is also expanding into new segments. As health consciousness grows, we may see an increase in models designed for vegan, vegetarian, or gluten-free sandwiches. These presses could come with features that ensure even cooking of different types of bread and fillings, accommodating a wider array of dietary requirements.

E-commerce has democratized the appliance market, and this trend is likely to continue. Online shopping means that customers can access a broader range of products from different corners of the world. For heavy-duty sandwich presses, this could mean that consumers have more choices and can purchase from brands that offer the latest in design and technology.

Globalization has its perks, but it also presents challenges. The future of heavy-duty sandwich presses will need to address the complexities of international trade, including compliance with various safety and quality standards across different regions. This will require manufacturers to be agile and adaptable, ensuring that their products meet the diverse needs of a global customer base.

Sustainability is a buzzword that’s here to stay. As consumers become more environmentally aware, they’re increasingly looking for products that are eco-friendly. The future of heavy-duty sandwich presses could include more sustainable materials and manufacturing processes, such as the use of recycled plastics and energy-efficient production methods.

Lastly, the rise of content creators and influencers is shaping the way products are marketed and consumed. For heavy-duty sandwich presses, this could mean a shift towards storytelling and brand narratives that resonate with the values and aspirations of today’s consumers. The future may not just hold new products, but also new ways of engaging with customers.

In conclusion, the future of heavy-duty sandwich presses is bright with possibilities. From innovative designs to smart technology and sustainability, these appliances are set to evolve in ways that not only enhance the culinary experience but also reflect the broader cultural shifts and technological advancements of our time.